Preparation method of thin-strip continuous casting low-magnetic anisotropy non-oriented silicon steel

A technology of magnetic anisotropy, oriented silicon steel, applied in the field of metallurgy, can solve the problem of affecting the rotation loss of the motor, not involving the anisotropy of magnetic properties, etc., to achieve low production cost, low anisotropy, and improved plate shape and plasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

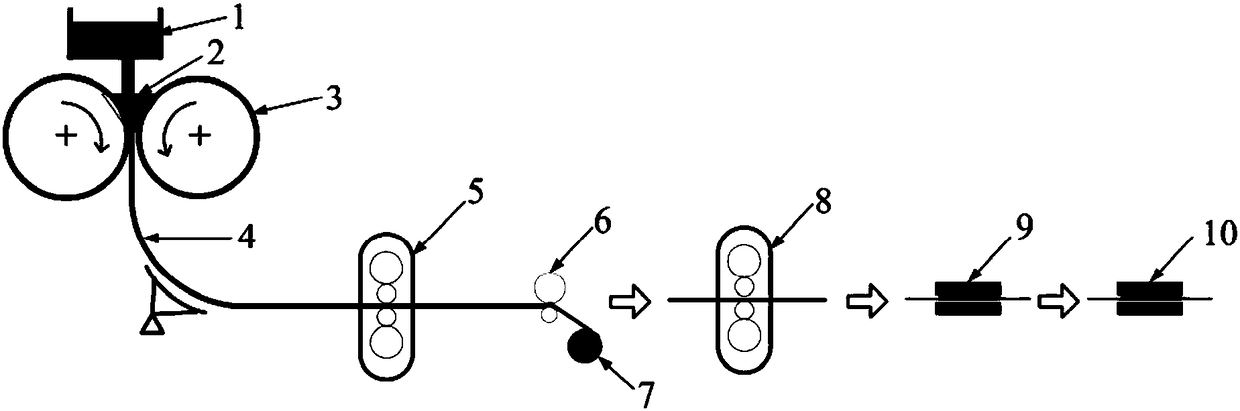

[0031] In this embodiment, the preparation method of thin strip continuous casting low magnetic anisotropy non-oriented silicon steel is carried out according to the following steps:

[0032] According to chemical composition (mass percentage) C 0.004%, Si 1.4%, Mn 0.10%, Al 0.4%, S0.003%, N0.003%, Sn 0.03%, P 0.008%, Nb+V+Ti≤0.008%, The rest is Fe. The molten steel is smelted. The superheated degree of the molten steel is 55°C. It is cast and rolled into a 1.70mm cast strip by a thin strip continuous casting machine. The casting rolls in the casting and rolling process are copper rolls.

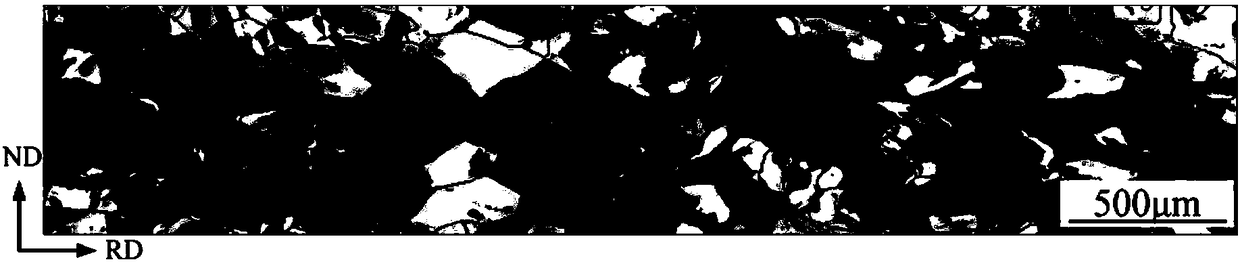

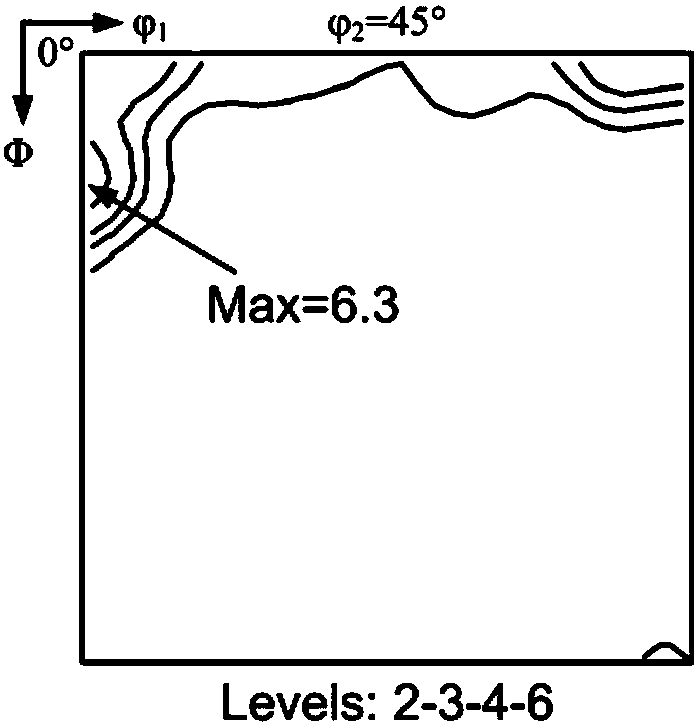

[0033] On-line hot rolling is carried out after the cast strip is rolled out, the hot rolling start temperature is 1020°C, the total hot rolling reduction is 55%, and it is cooled to room temperature after being crimped at 450°C. figure 2 It is the metallographic structure of cast strip hot-rolled sheet, image 3 It is the macroscopic texture of hot-rolled cast strip. It can be se...

Embodiment 2

[0051] In this embodiment, the preparation method of thin strip continuous casting low magnetic anisotropy non-oriented silicon steel is carried out according to the following steps:

[0052] According to chemical composition (mass percentage) C 0.004%, Si 2.0%, Mn 0.2%, Al 0.4%, S0.004%, N 0.003%, Sn 0.05%, P 0.01%, Nb+V+Ti≤0.008%, the rest For Fe. The molten steel is smelted, the superheated degree of the molten steel is 70°C, and it is cast and rolled into a 2.5mm cast strip by a thin strip continuous casting machine. The casting rolls in the casting and rolling process are copper rolls.

[0053] On-line hot rolling is carried out after the cast strip is rolled out, the hot rolling start temperature is 1180°C, the total reduction of hot rolling is 64%, and it is cooled to room temperature after being crimped at 500°C.

[0054] The hot-rolled cast strip was pickled to remove scale, and then cold-rolled to 0.50mm, with a cold-rolling reduction of 59%.

[0055] Col...

Embodiment 3

[0060] In this embodiment, the preparation method of thin strip continuous casting low magnetic anisotropy non-oriented silicon steel is carried out according to the following steps:

[0061] According to chemical composition (mass percentage) C 0.003%, Si 1.7%, Mn 0.06%, Al 0.3%, S0.003%, N 0.003%, Sn 0.03%, P 0.005%, Nb+V+Ti≤0.008%, the rest For Fe. The molten steel is smelted, the superheat of the molten steel is 40°C, and it is cast and rolled into a 2.0mm cast strip by a thin strip continuous casting machine. The casting rolls in the casting and rolling process are copper rolls.

[0062] On-line hot rolling is carried out after the cast strip is rolled out, the hot rolling start temperature is 1100°C, the total hot rolling reduction is 52%, and it is cooled to room temperature after being crimped at 480°C.

[0063] The hot-rolled cast strip was pickled to remove scale, and then cold-rolled to 0.50mm with a reduction of 48%.

[0064] Cold-rolled sheet at 40% N ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com