Lithium Ni-Co aluminate positive electrode material co-doped with negative ions and positive ions and preparation method of positive electrode material

A technology of nickel cobalt lithium aluminate, anion and cation, used in battery electrodes, electrical components, circuits, etc., can solve the problems of cycle life and poor capacity of ternary cathode materials, and achieve enhanced electrochemical performance, reduced oxygen evolution, stable The effect of material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

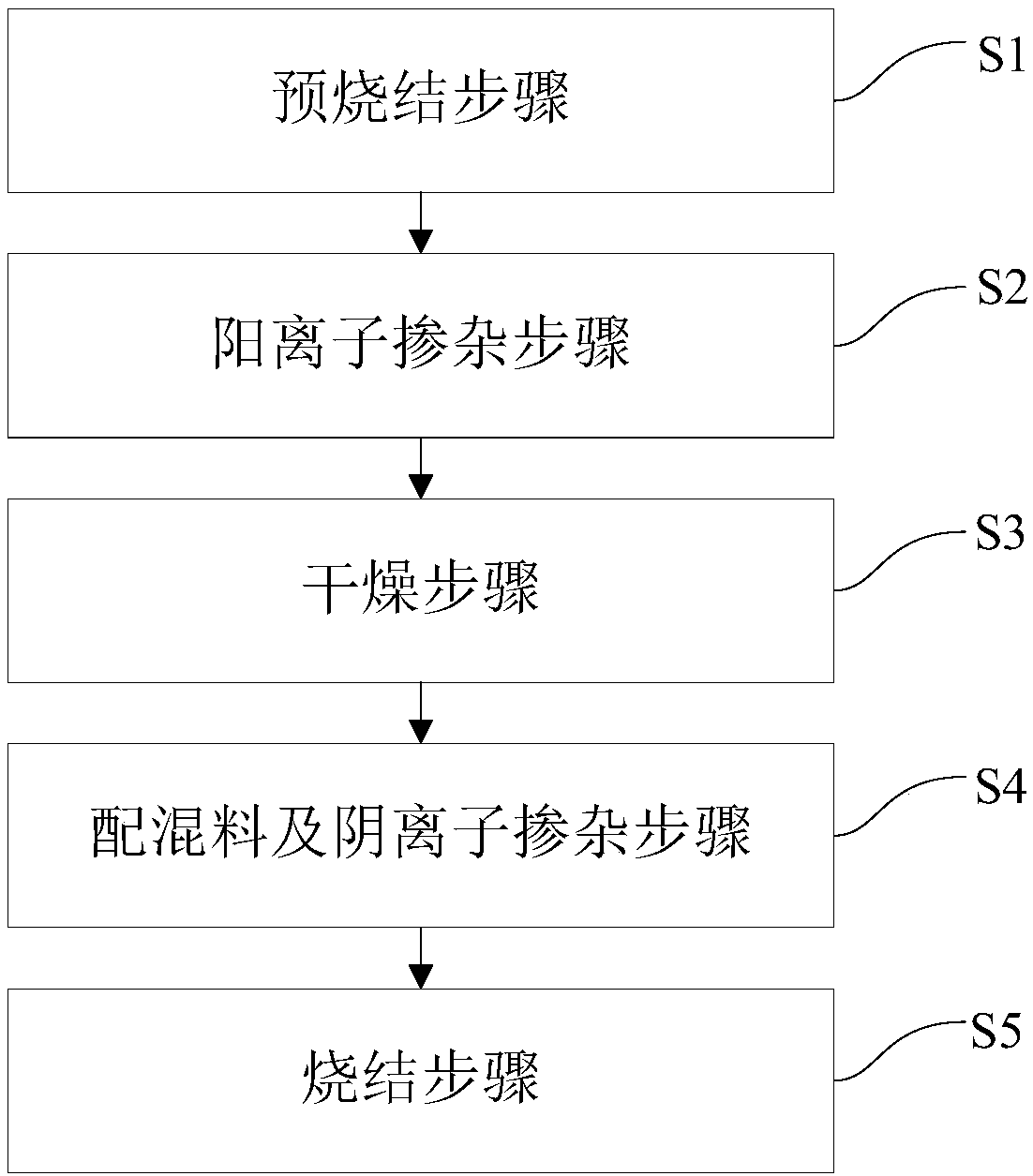

[0022] Such as figure 1 As shown, the preparation method of the nickel-cobalt-lithium-aluminate positive electrode material provided by the invention provided by mixed anion and cation doping comprises the following steps:

[0023] S1. Pre-sintering step: Weigh the nickel-cobalt-lithium-aluminate precursor, spray a certain amount of baking soda solution and F solution, then mix evenly, transfer to the sintering furnace for low-temperature pre-sintering, and then rapidly heat up for a period of time Pre-sintering at high temperature to obtain a porous pre-sintered precursor.

[0024] The mass percent concentration of the baking soda solution is 5%-10%, the spraying amount accounts for 1%-10% of the total mass of the nickel-cobalt lithium aluminate precursor, and the mass percent concentration of the F solution is 0.2%-1.5%, The F solution accounts for 1%-5% of the total mass of the nickel cobalt lithium aluminate precursor, and the F solution is NH4F, NaF, MgF 2 One of them; ...

Embodiment

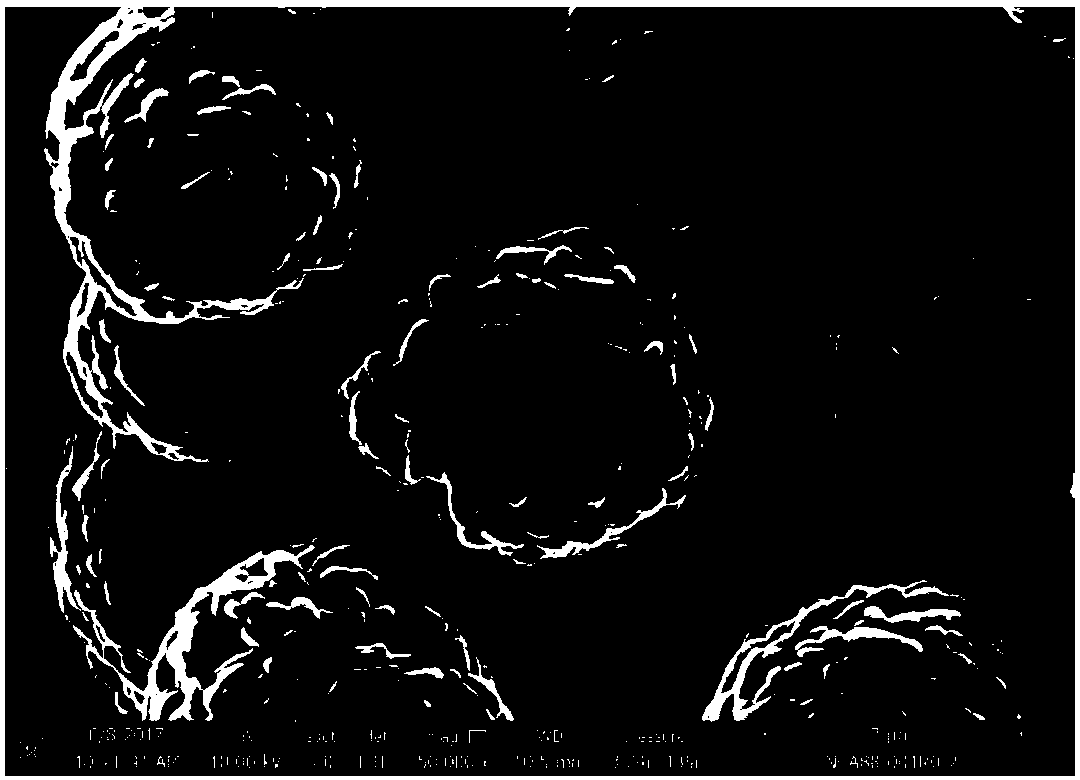

[0036] 1) Weigh 100g nickel cobalt lithium aluminate precursor, and spray 5% baking soda solution and 0.2% NH 4 F solution, mixed evenly, and then transferred to the sintering furnace for pre-sintering. The mass ratio of the amount sprayed on the baking soda solution to the precursor of lithium nickel cobalt aluminate is 5%, and the spray amount of F solution accounts for 2% of the total mass of the precursor of lithium nickel cobalt aluminate. The temperature was raised rapidly at 5°C / min, and the temperature was raised to 600°C for 10 hours to obtain a porous pre-calcined precursor.

[0037] 2) Weigh 100g of the pre-sintered precursor that has formed a hole shape, and add the pre-sintered precursor to 1% NbCl while stirring and heating 5 solution and 2% MgCl 2solution, and then mixed uniformly to obtain a spare sample. The mass ratio of the pre-calcined precursor to the mixed solution of Mg and Nb was 1:10, the stirring temperature was 40° C., and the stirring time was 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com