Electronic component manufacturing method

A technology of electronic components and manufacturing methods, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of resin overflowing to the bottom of the chip, easy impact leads, chip scrapping, etc., to prevent clogging and sealing Good performance, good injection molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

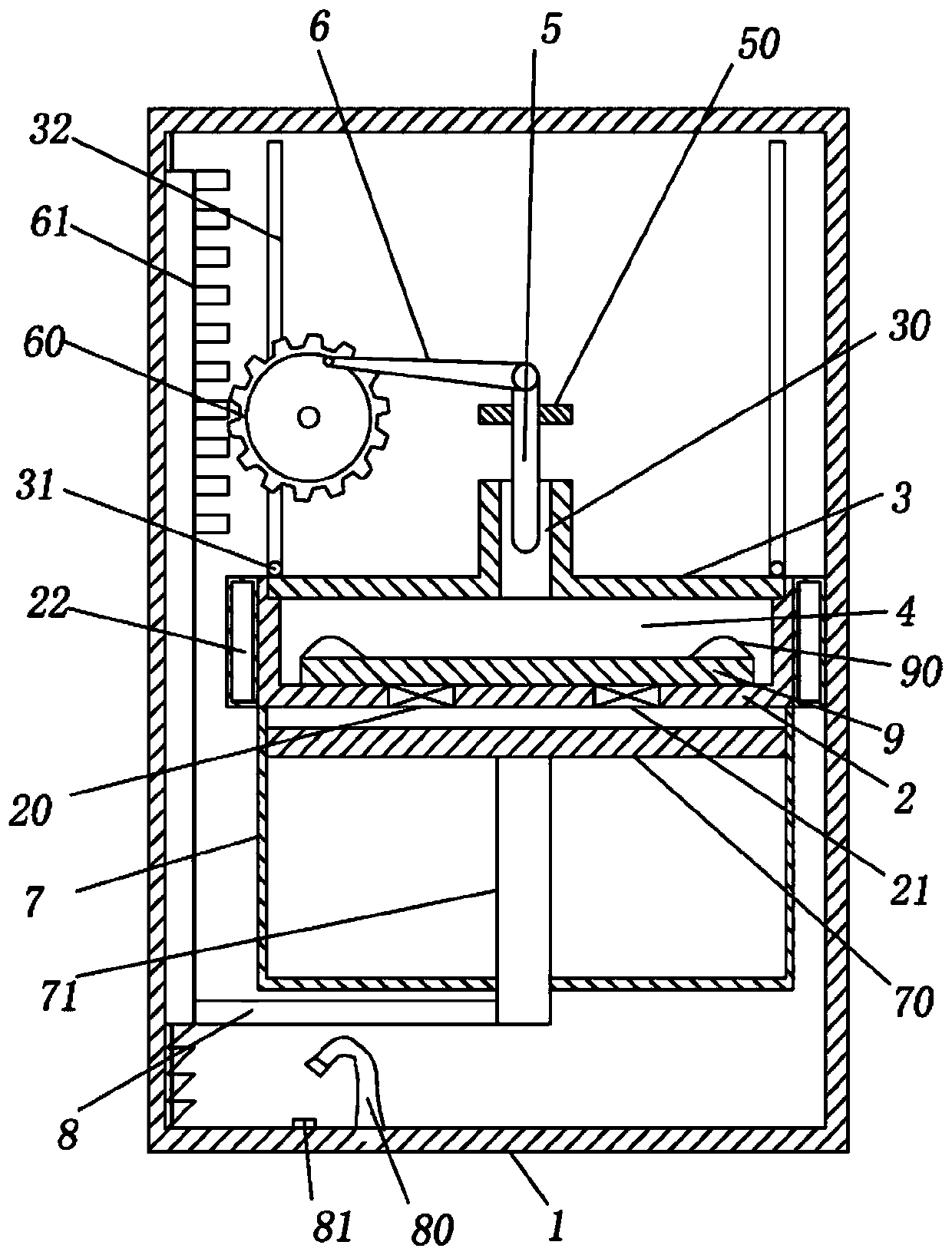

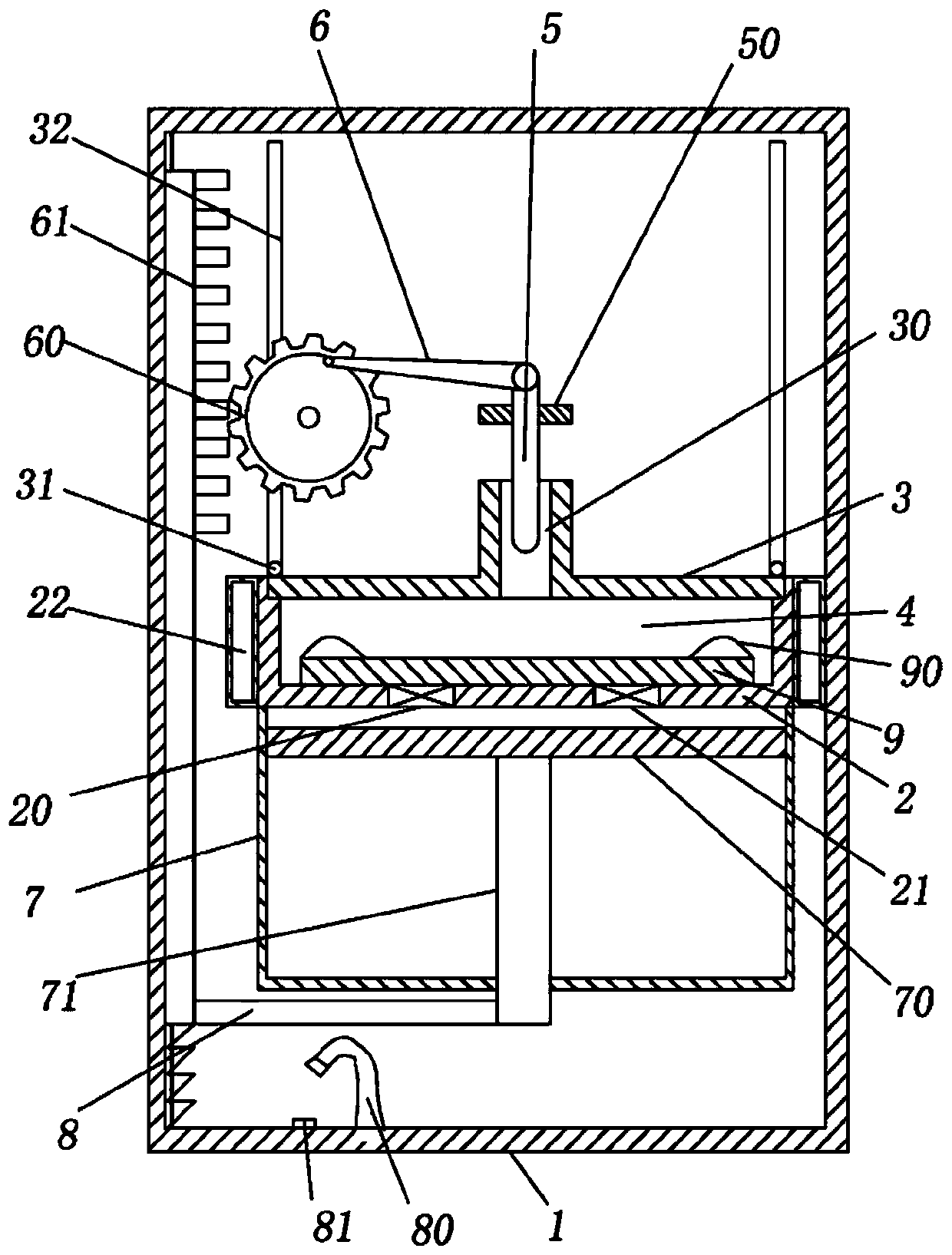

[0027] basically as attached figure 1 shown:

[0028] The electronic component manufacturing method adopts an injection mold for plastic sealing, and the injection mold includes a frame 1, a mold, a drainage mechanism and an air control mechanism.

[0029] The mold is in the shape of a cylinder as a whole, and includes a fixing groove 2 and a cover plate 3 . The top of the fixed groove 2 is open, and an annular groove is opened on the side wall of the top of the fixed groove 2; Port 21; Fixed groove 2 is provided with an annular cooling groove 22 on the outer circumference for cooling the mold. The cover plate 3 is used to cover the top of the fixing groove 2, and the cover plate 3 is slidably connected in the groove on the top of the fixing groove 2; the center of the cover plate 3 is provided with a raised injection port 30. An injection cavity 4 is formed between the fixing groove 2 and the cover plate 3 . In order to give the cover plate 3 enough sliding space, a slidi...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that: when the gas is preset in step A, the distance from the piston rod to the top of the cylinder when the piston rod is pulled down is equal to one-eighth of the height of the cylinder; Cool and shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com