Method for measuring blending uniformity of cigarette cut tobacco

A technology of uniformity and shredded tobacco, which is applied in the field of tobacco processing, can solve problems such as large task load, certain requirements for reagent consumables, complex data processing, etc., and achieve the effect of small sample size, objective experimental results, and simple equipment and operation processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

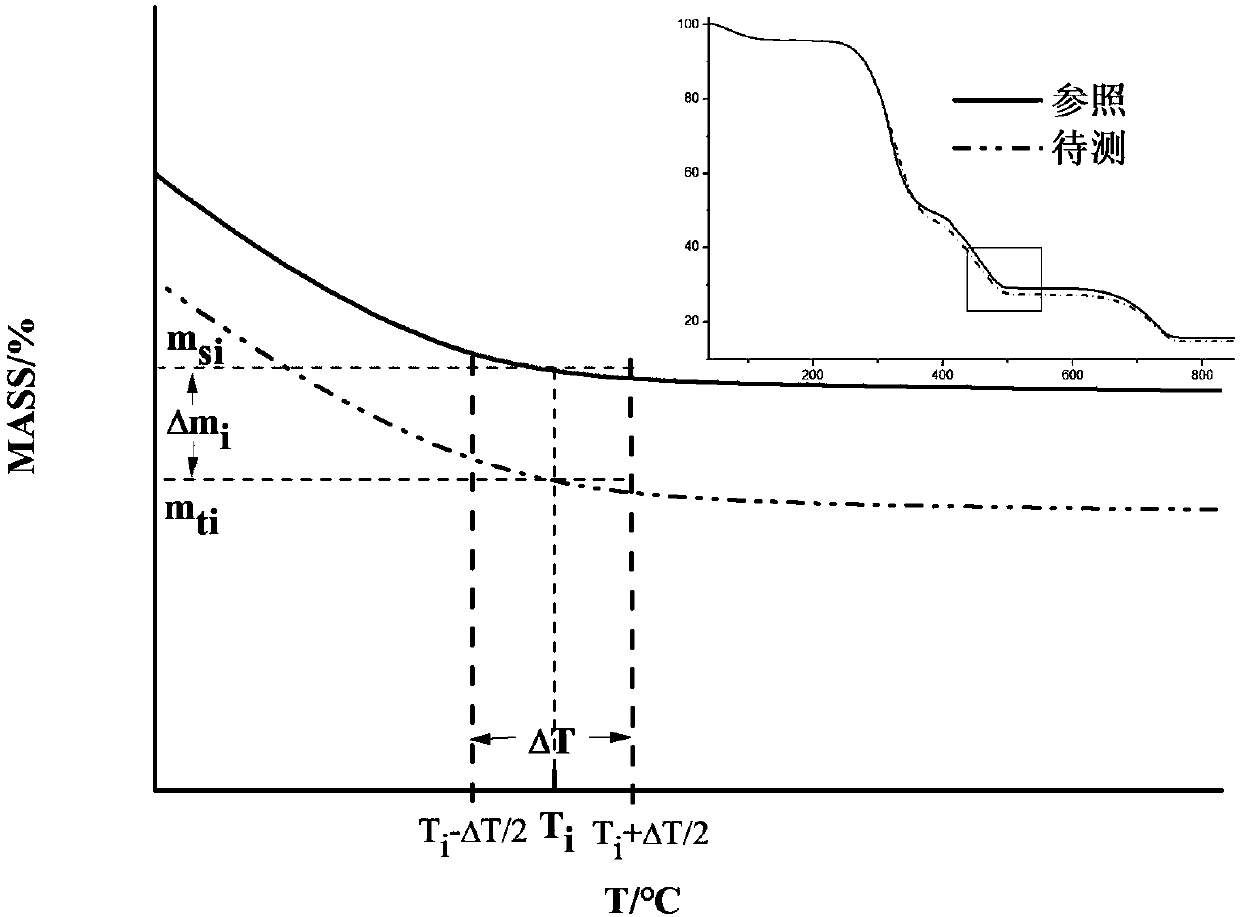

Method used

Image

Examples

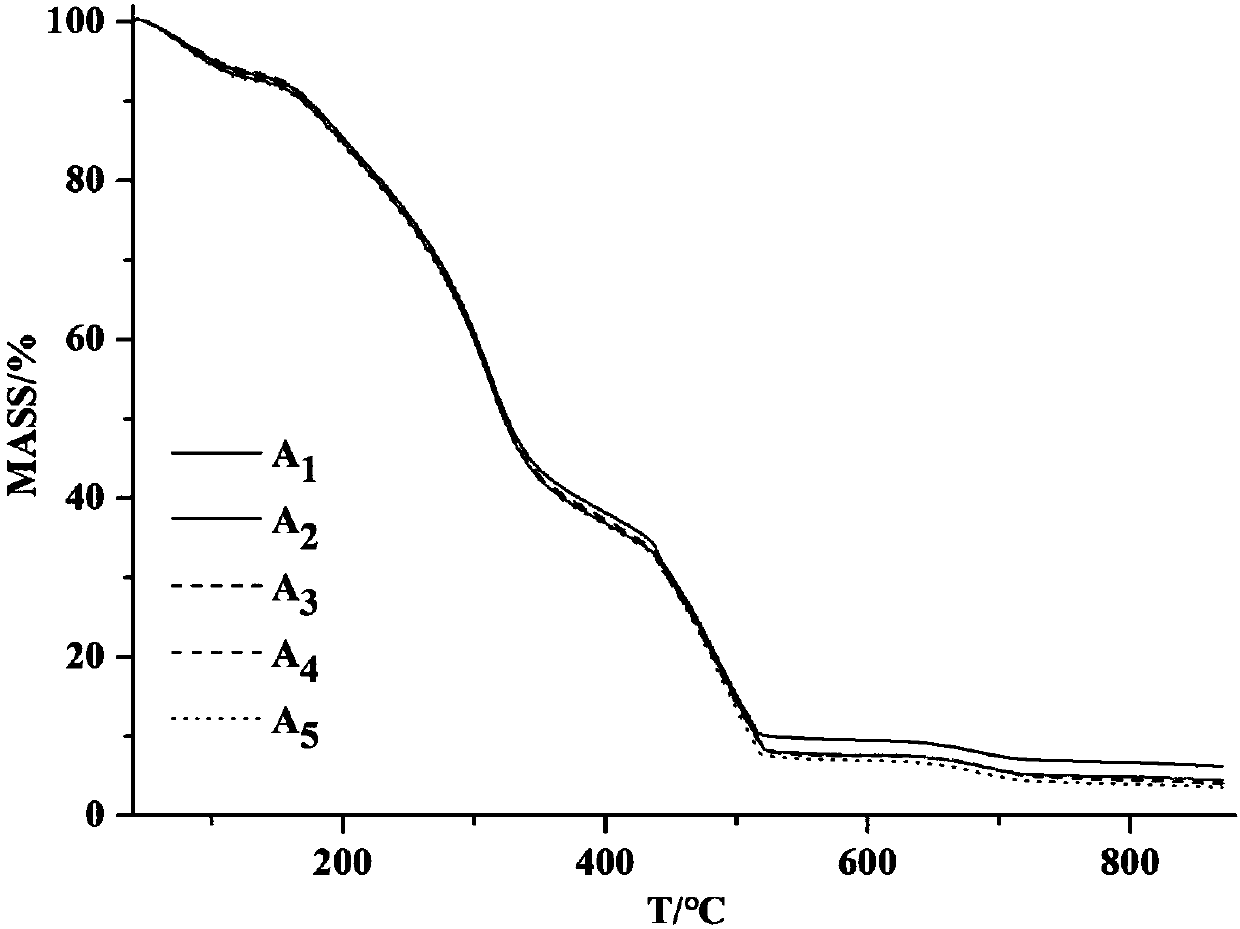

Embodiment 1

[0036] Embodiment 1. In this embodiment, a certain cigarette specification A is taken as an example to measure the blending uniformity of shredded tobacco. The specific operation includes the following steps:

[0037] (1) Sampling and pretreatment of cut tobacco blending samples

[0038] In the production time of a batch, take a sample at the cross-section of the vibrating groove at the flavoring outlet of blended shredded tobacco, take a sample every 1 hour, take a sample 5 times in total, take a sample of 20g each time, and use it as a sample each time; The samples were respectively placed in a constant temperature and humidity environment at (22±1)°C and a relative humidity of (60±2)% to equilibrate for 48 hours before use.

[0039] (2), thermogravimetric analysis test of blended shredded tobacco sample

[0040] Grind the balanced blended cut tobacco sample through a 40-mesh sieve, weigh (10±1) mg of the sample, and place it in an alumina crucible of a thermogravimetric an...

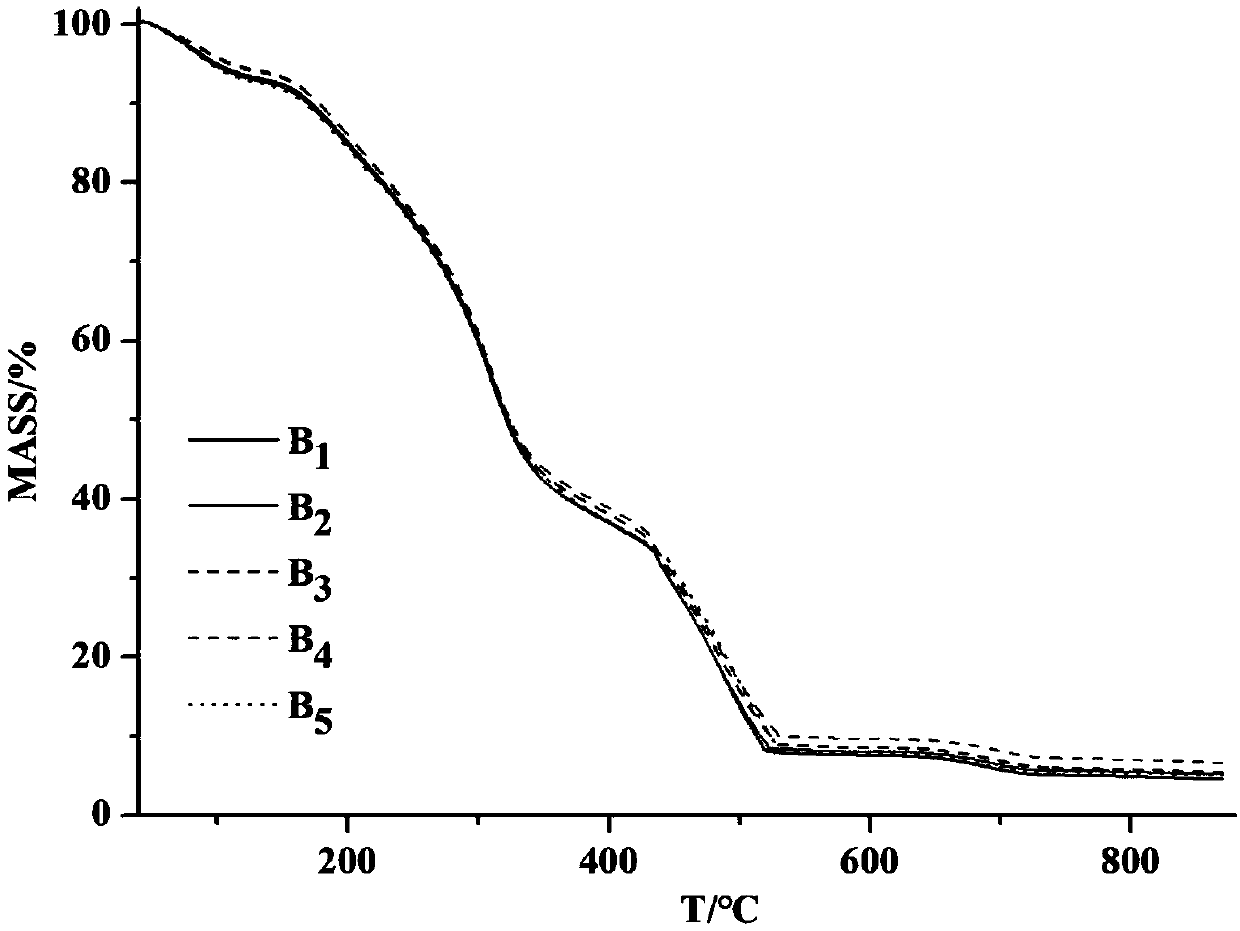

Embodiment 2

[0052] Embodiment 2. In this embodiment, a certain cigarette specification B is taken as an example to measure the blending uniformity of shredded tobacco. The specific operation includes the following steps:

[0053] (1) Sampling and pretreatment of cut tobacco blending samples

[0054] In the production time of a batch, take a sample at the cross-section of the vibrating groove at the flavoring outlet of blended shredded tobacco, take a sample every 1 hour, take a total of 5 samples, each sampling 20g, each time as a sample; The samples were placed in a constant temperature and humidity environment at (22±1)°C and a relative humidity of (60±2)% to equilibrate for 48 hours for later use.

[0055] (2), thermogravimetric analysis test of blended shredded tobacco sample

[0056] Grind the balanced blended cut tobacco sample through a 40-mesh sieve, weigh (10±1) mg of the sample, and place it in an alumina crucible of a thermogravimetric analyzer for thermal analysis testing. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com