Minitype model for simulating oil reservoir and method for conducting petroleum displacement experiment by using minitype model

A technology for displacement experiments and oil simulation, which is used in material analysis by optical means, earthwork drilling, preparation of samples for testing, etc. It can solve problems such as high-cost visualization methods, hindering research and development, and huge experimental equipment. Achieve good visualization performance, simple processing process, and small equipment volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

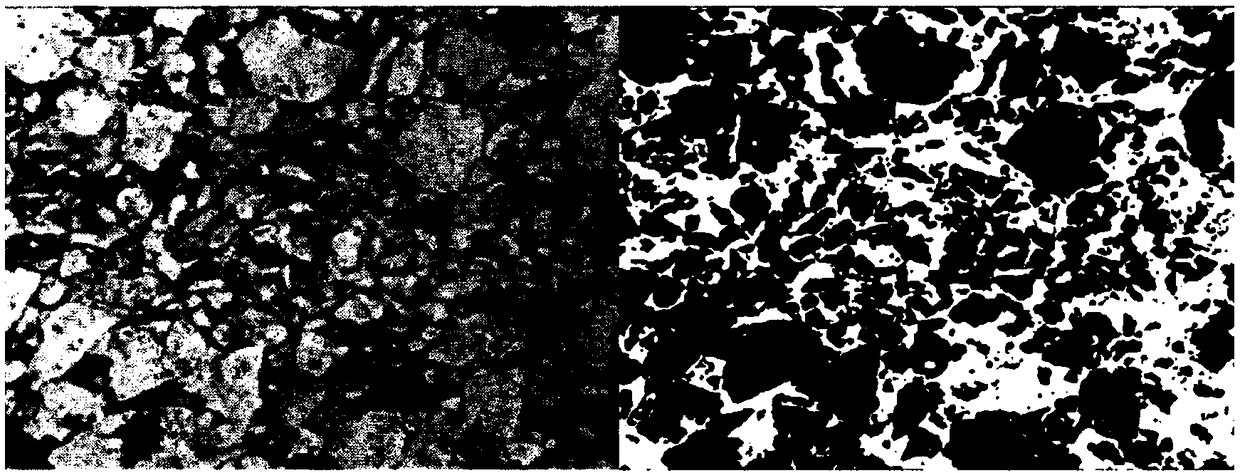

[0028] First, use Matlab software to process the rock formation photos, the rock formation photos and the processed photos are as follows figure 1 shown.

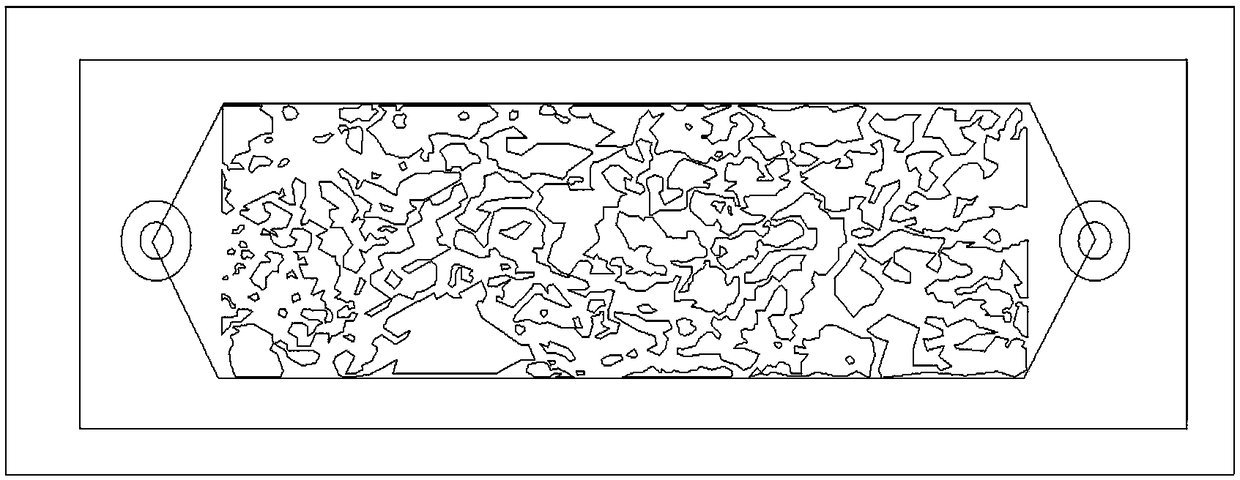

[0029] Use the image processing software Adobe Photoshop and Adobe Illustrator to make the processed photo into a photomask, and use su-8 photoresist to copy the rock formation structure on the surface of the silicon wafer. Choose PDMS as raw material, use molding method to make model structure layer, choose glass sheet as bonding layer, and use oxygen plasma bonding method to complete the bonding of micromodel. Chips that are eventually made into miniature models such as figure 2 , image 3 , Figure 4 As shown, the chip of the miniature model includes a PDMS structure layer 1, a glass bonding layer 2, a rock structure 3, an entrance and exit 4, and an entrance and exit buffer zone 5; the glass bonding layer 2 is set on the PDMS structure layer 1, and the rock structure 3 is set On the glass bonding layer 2 , an inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com