Continuous casting and rolling method for preparing wire rod for 5183 aluminum alloy welding wire

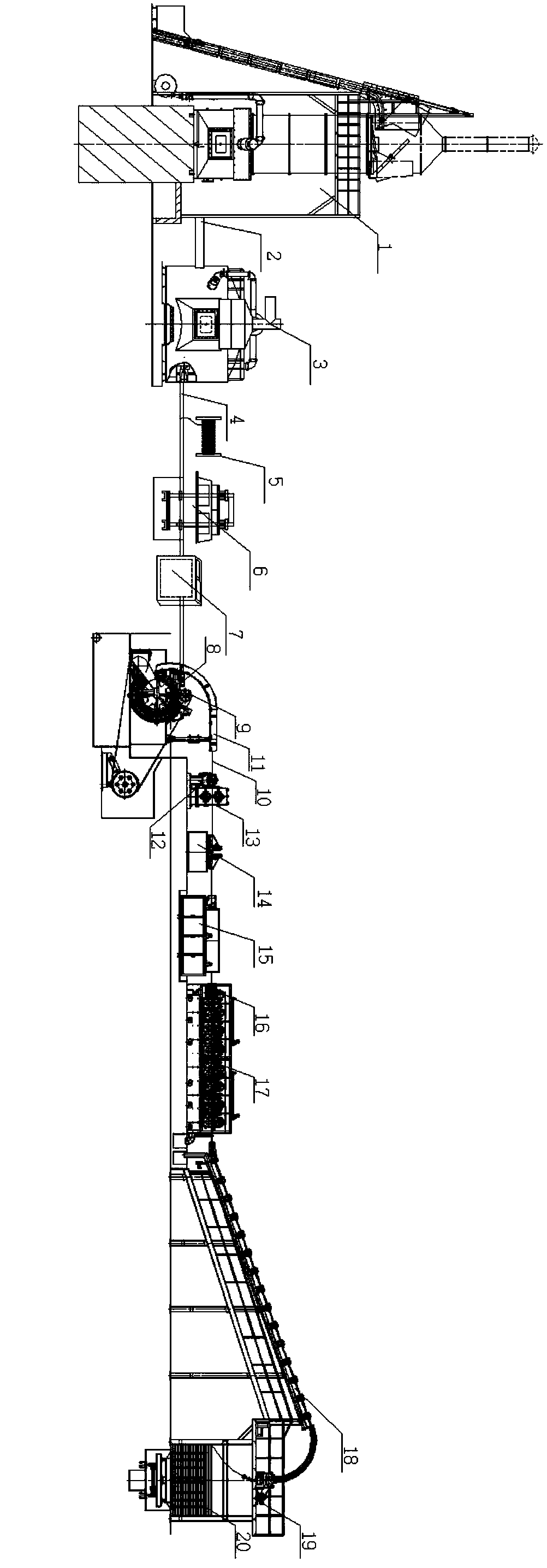

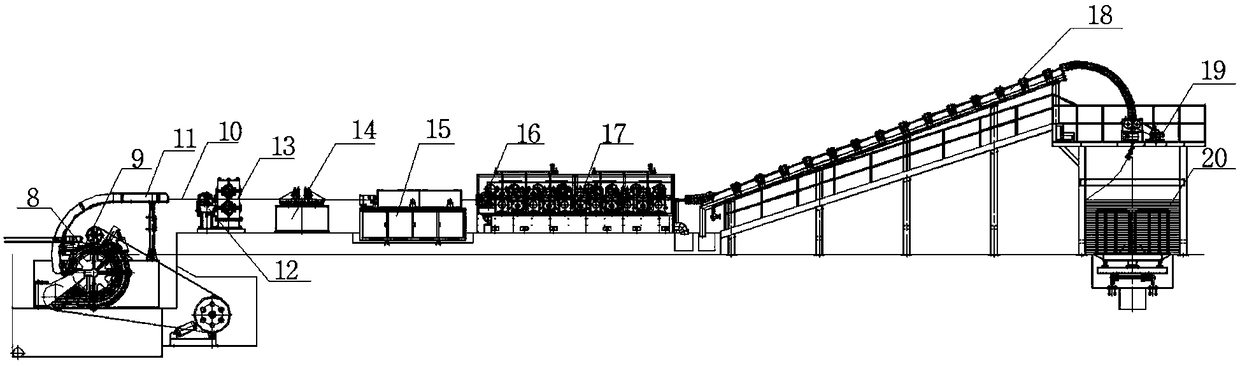

A technology of aluminum alloy welding wire, continuous casting and rolling, which is applied in the field of continuous casting and rolling for the preparation of wire rods for 5183 aluminum alloy welding wire, which can solve the problems of high tool and mold consumption and energy consumption, low product yield, and large floor space. problems, to achieve the effects of high production efficiency, low product scrap rate, and small hidden dangers of safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

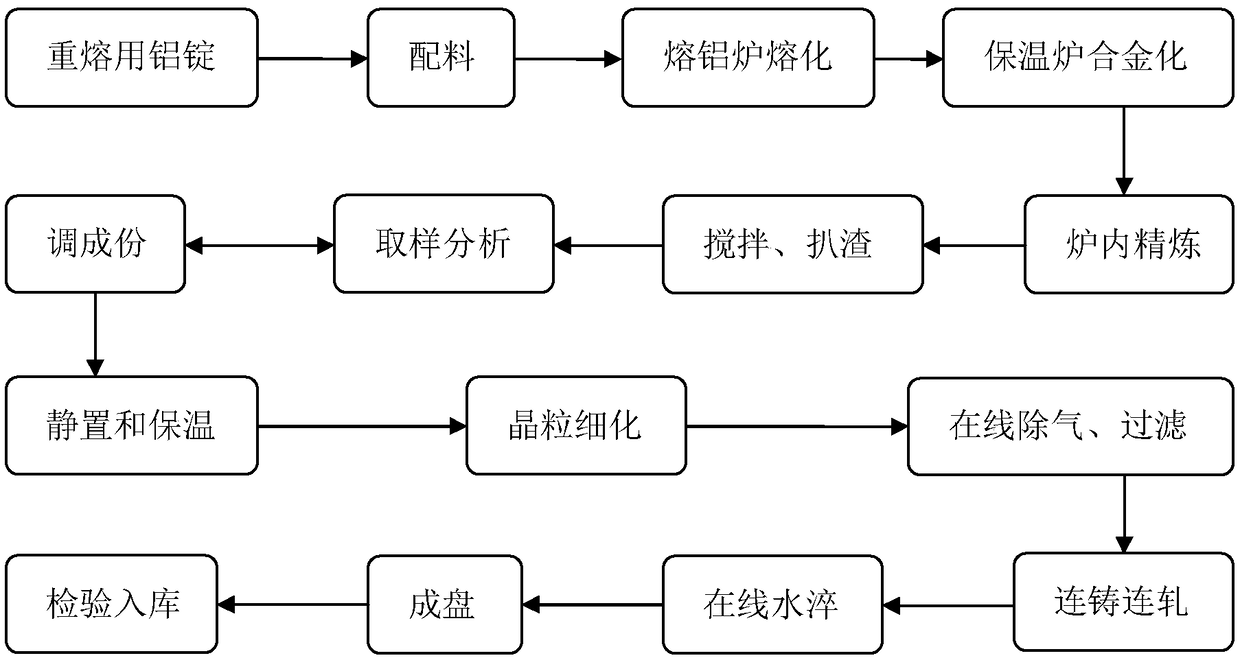

[0039] The concrete steps of the continuous casting and rolling method for preparing wire rods for 5183 aluminum alloy welding wire are as follows:

[0040] The first step is to carry out batching, calculate the returned materials, aluminum ingots for remelting, magnesium ingots and intermediate alloys, select the returned materials with a Si content of less than 0.06%, and the 5-ton grade is Al99.90 b (Wt, Si<0.06%) aluminum ingots for remelting,

[0041] The second step is smelting. The smelting equipment includes a vertical aluminum melting furnace and a holding furnace. The recycled material and aluminum ingots for remelting are loaded into the vertical aluminum melting furnace from the feeding port for smelting. The melting temperature is 700 ° C ~ 720 ° C. ℃, when the aluminum material in the shaft furnace is melted, the aluminum melt in the vertical aluminum melting furnace is introduced into the holding furnace through the diversion launder, and the alloying of the alu...

Embodiment 2

[0050] The concrete steps of the continuous casting and rolling method for preparing wire rods for 5183 aluminum alloy welding wire are as follows:

[0051] The first step is to carry out batching, calculate the returned materials, aluminum ingots for remelting, magnesium ingots and intermediate alloys, select the returned materials with a Si content of less than 0.06%, and the 5-ton grade is Al99.90 b (Wt, Si<0.06%) aluminum ingots for remelting,

[0052] The second step is smelting. The smelting equipment includes a vertical aluminum melting furnace and a holding furnace. The recycled material and aluminum ingots for remelting are loaded into the vertical aluminum melting furnace from the feeding port for smelting. The melting temperature is 710 ° C ~ 730 ° C ℃, when the aluminum material in the shaft furnace is melted, the aluminum melt in the vertical aluminum melting furnace is introduced into the holding furnace through the diversion launder, and the alloying of the alum...

Embodiment 3

[0061] The concrete steps of the continuous casting and rolling method for preparing wire rods for 5183 aluminum alloy welding wire are as follows:

[0062] The first step is to carry out batching, calculate the returned materials, aluminum ingots for remelting, magnesium ingots and intermediate alloys, select the returned materials with a Si content of less than 0.06%, and the 5-ton grade is Al99.90 b (Wt, Si<0.06%) aluminum ingots for remelting.

[0063] The second step is to smelt. The smelting equipment includes a vertical aluminum melting furnace and a holding furnace. The recycled material and aluminum ingots for remelting are put into the vertical aluminum melting furnace from the feeding port for melting. When the aluminum material in the vertical furnace melts After completion, the temperature of the aluminum melt in the water storage chamber is raised to 730°C to 750°C, and then the aluminum melt in the vertical aluminum melting furnace is introduced into the holding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com