Preparing method of xylitol

A technology of xylitol and xylose, applied in the field of preparation of xylitol, can solve problems such as large amount of coenzyme, and achieve the effects of saving production cost and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

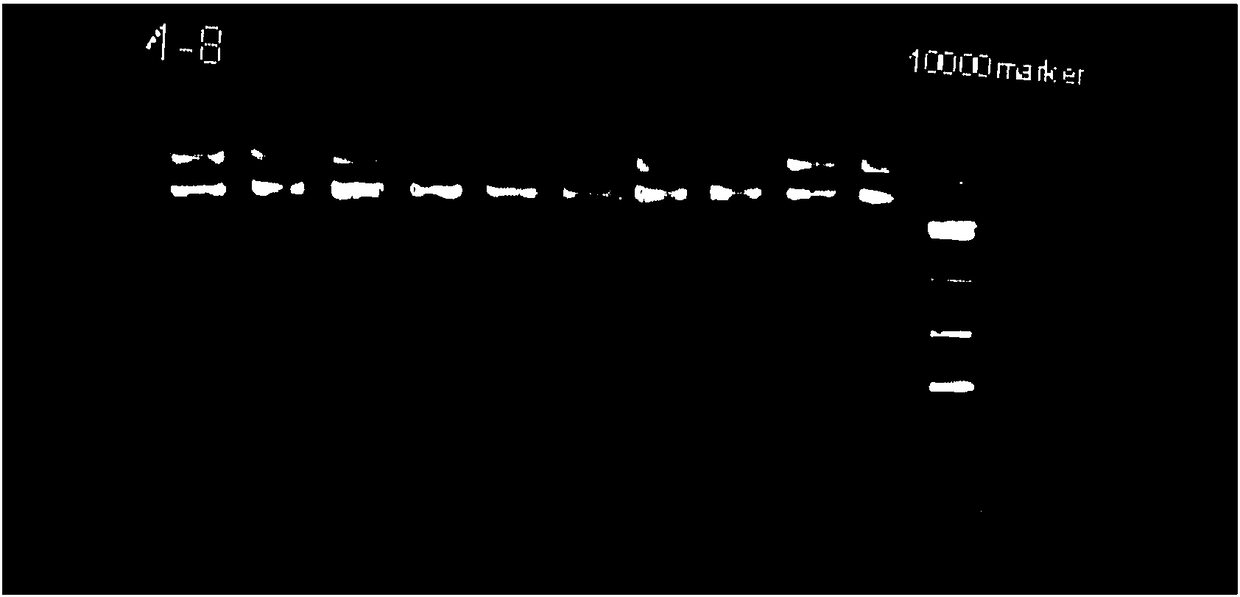

[0032] Induction and expression of embodiment 1 xylose reductase

[0033]1. The xylose reductase gene sequence (GenBank: AB002105.2) of Candida tropicalis IFO 0618 was found in the NCBI database, and the xylose reductase gene sequence was optimized according to the codon preference of Escherichia coli. After optimization The nucleotide sequence is shown in SEQ ID NO: 1, and the nucleotide sequence was synthesized by Jinweizhi Company.

[0034] Analysis of rare codons: The rare codons were mainly analyzed by the software E.coli Codon Usage Analysis 2.0 to obtain the codons whose relative frequency of use in Escherichia coli was lower than the threshold (10‰).

[0035] Optimize rare codons: optimize the codons whose usage frequency is lower than the threshold according to the usage frequency of different codons in E. coli.

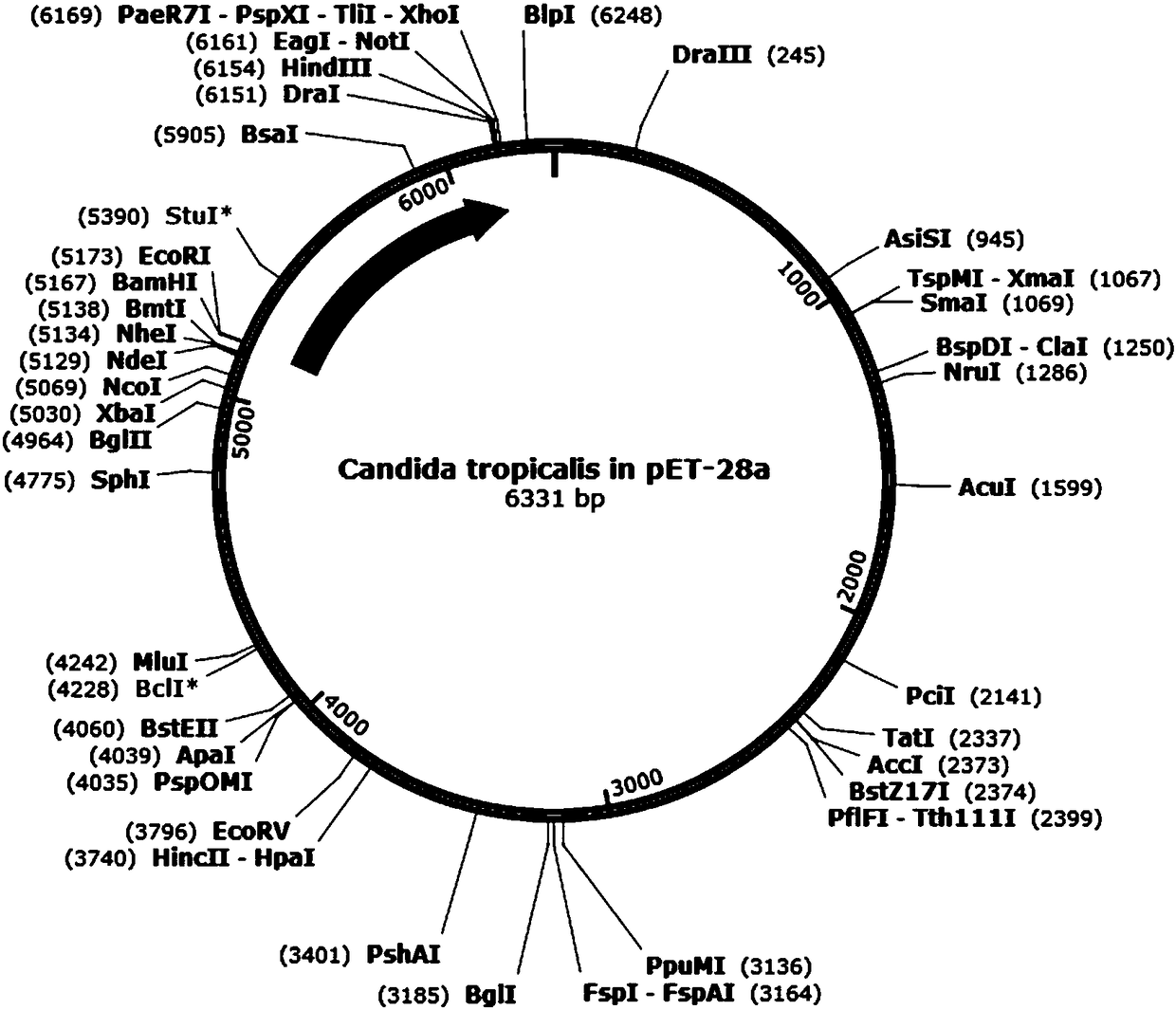

[0036] The optimized xylose reductase gene was subcloned between the EcoRI and HindIII restriction sites of plasmid pET-28a to form a recombinant plasmid. ...

Embodiment 2

[0064] The enzyme-catalyzed reaction is added according to the following system:

[0065]

[0066] After enzymolysis, heat to inactivate the enzyme, and then filter through the water-based membrane to detect the product components in the liquid phase. The liquid phase conditions: (1) The chromatography column is Aminex HPX-87C, the mobile phase is ultrapure water, and the flow rate is 0.6mL / min , the column temperature was 80°C, and detected with a refractometer RID. The results showed that xylose and glucose had been completely converted. (2) The chromatographic column is Aminex HPX-87H, and the mobile phase is 5mMH 2 SO 4 , flow rate 0.4mL / min, column temperature 45°C, detect xylitol content with a refractometer RID. The conversion rate of xylitol in the product is 98%, and the concentration can reach 146.23g / L; the conversion rate of gluconic acid is 95%, and the concentration can reach 185.05g / L, and a very small amount of sorbitol and xylonic acid are also generated...

Embodiment 3

[0071] The method is the same as in Example 2, adding and carrying out the enzyme-catalyzed reaction according to the following system:

[0072]

[0073]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com