A kind of oxygen-coal ratio control method

A control method and technology of oxygen-to-coal ratio, applied in the field of control, can solve the problems of insufficiently comprehensive process control and insufficiently advanced gasification island control, and achieve the effects of high degree of automation, sensitive temperature adjustment, and avoidance of misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

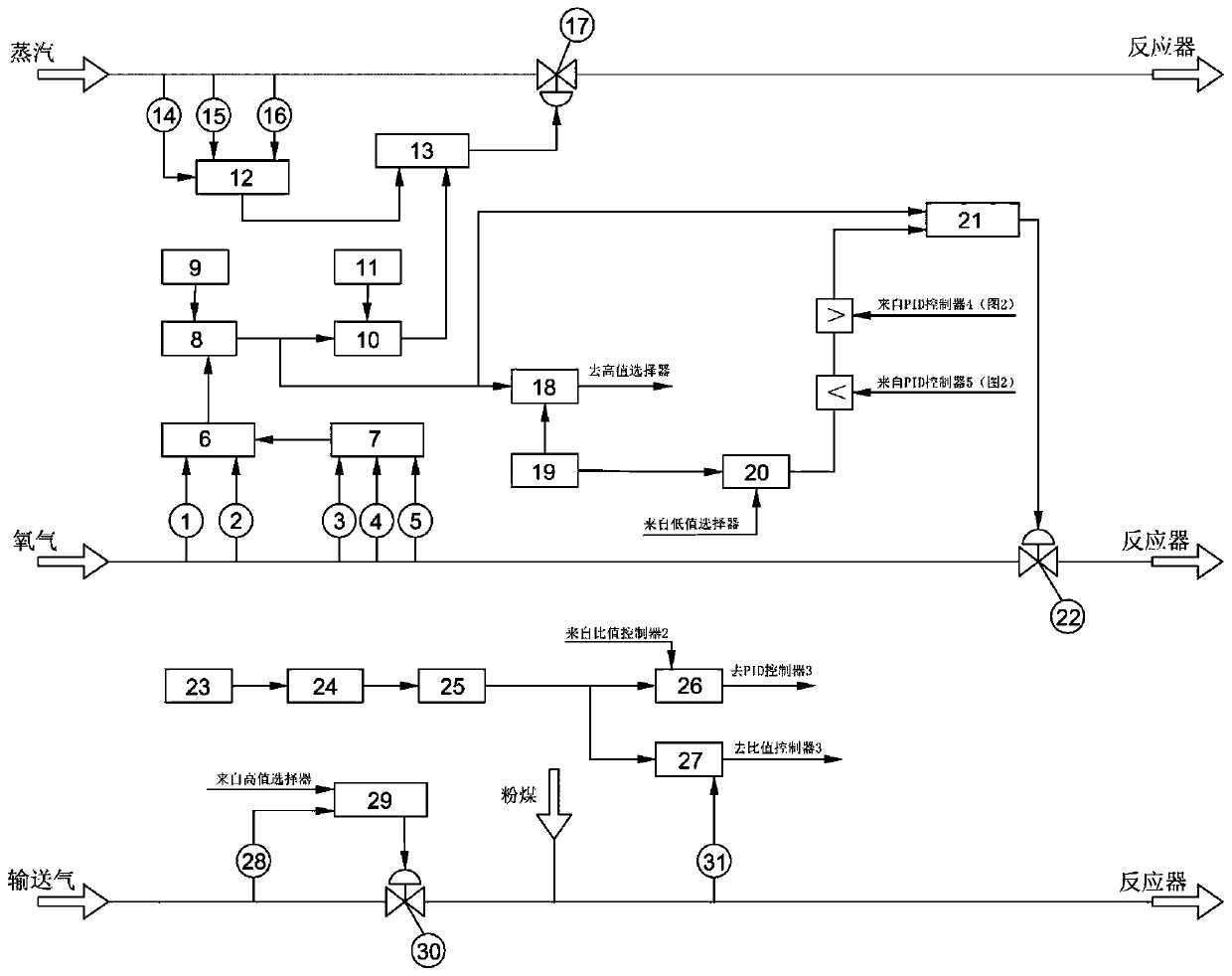

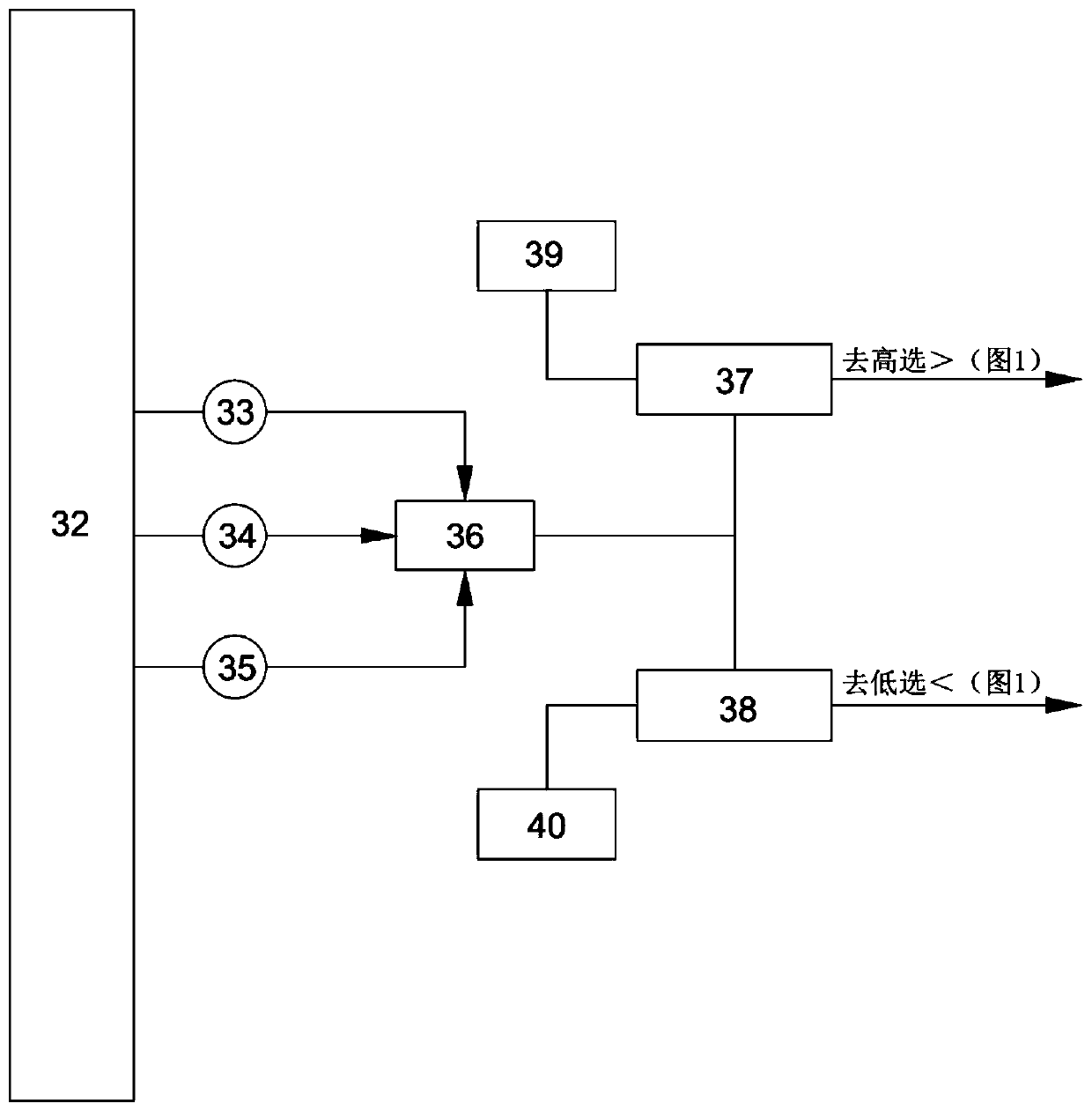

[0021] see figure 1 , 2, the control method of the present invention is as follows:

[0022] 1) Determination of oxygen flow:

[0023] First, oxygen enters the median value selector (7) through the flow transmitters FT1A(3), FT1B(4), and FT1C(5), and after taking the median value, it is combined with the pressure transmitter PT1(1) and temperature transmitter TT1 (2) enter the first temperature-pressure compensator (6) together, the result that is exported by the first temperature-pressure compensator (6) and oxygen purity input (9) enter oxygen purity controller (8) together, oxygen purity controller ( 8) The output value is the actual value of the oxygen flow;

[0024] 2) Oxygen / steam ratio control: The flow of steam changes with the flow of oxygen, and the relationship is ratio control. The oxygen purity controller (8) and the steam / oxygen ratio coeffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com