Odor-removing composition as well as preparation method and application thereof

A composition and plant extract technology, applied in the field of deodorization, can solve the problems of difficult to solve the problem of environmental pollution caused by peculiar smell, inability to ensure air quality, poor effect of removing peculiar smell, etc. Bacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

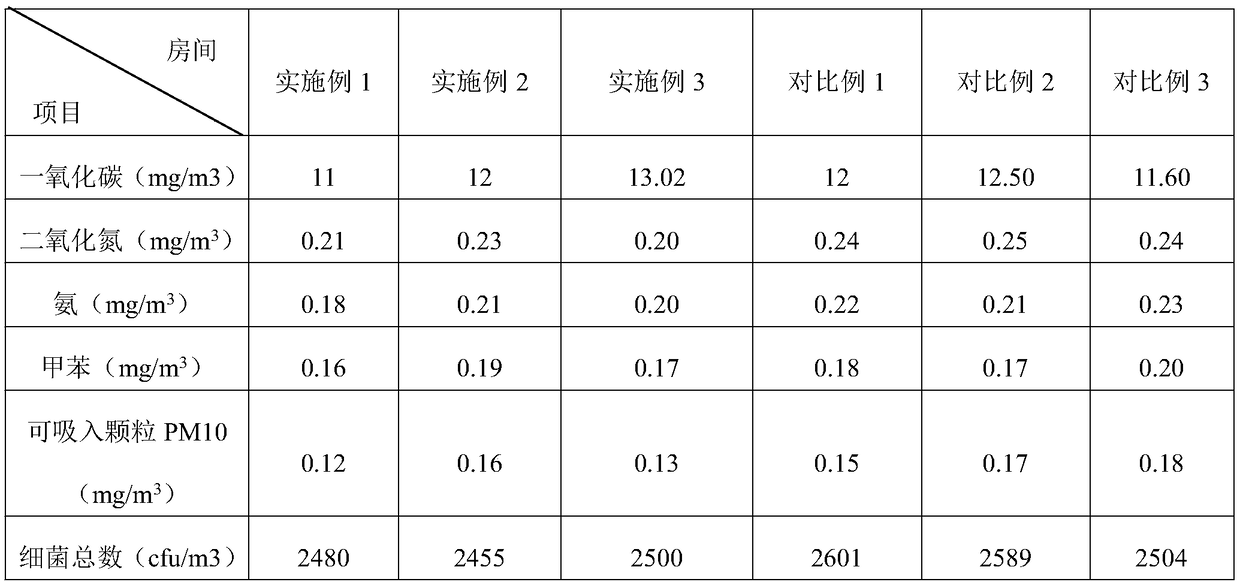

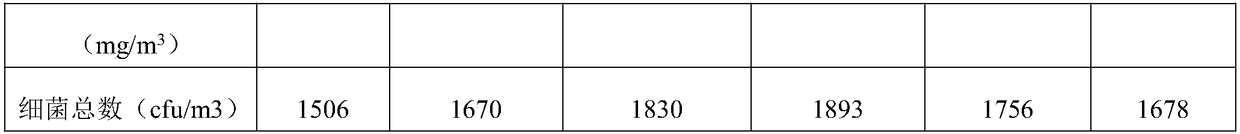

Examples

preparation example Construction

[0023] The preparation method of above-mentioned deodorant composition comprises:

[0024] S1: Put ultra-high fluidity thermoplastic elastomer, zeolite powder, stearic acid, wood chips, and medical stone into a mixer at a temperature of 120-135°C and a stirring speed of 200-300r / min and stir for 5-10 minutes to obtain a mixture A;

[0025] Before the step of preparing the mixture A in the step S1, grind the zeolite powder, medical stone, wood chips, and saponins to 300-600 mesh;

[0026] S2: Add 8-10 parts to the mixture A, cactus plant extract, negative ion powder, dioctyl sodium dibutyrate sulfonate, sodium lauryl sulfate, boric acid, and saponins. ℃, the stirring speed is 200-300r / min stirrer 10-15min to obtain the mixture B;

[0027] S3: put the mixture B into a single-screw extruder and granulate to obtain a deodorizing composition.

[0028] The above-mentioned deodorant composition can be used as a processing aid for automotive trim materials, an additive for building...

Embodiment 1

[0030] The deodorizing composition includes the following raw materials in parts by weight: 10 parts of ultra-high fluidity thermoplastic elastomer, 20 parts of zeolite powder, 2 parts of stearic acid, 0.5 part of dioctyl sodium dibutyrate, 10 parts 0.1 part of sodium dialkyl sulfate, 8 parts of medical stone, 12 parts of cactus plant extract, 4 parts of sawdust, 5 parts of negative ion powder, 3 parts of boric acid, 4 parts of saponins.

[0031] The preparation method of above-mentioned deodorant composition comprises:

[0032] S1: Put ultra-high fluidity thermoplastic elastomer, zeolite powder, stearic acid, and wood chips into a mixer at a temperature of 120°C and a stirring speed of 200r / min and stir for 5 minutes to obtain a mixture A;

[0033] Before the step of preparing the mixture A in the above-mentioned step S1, grind the zeolite powder, medical stone, wood chips, and saponins to 300 mesh;

[0034] S2: Add medical stone, cactus plant extract, negative ion powder, b...

Embodiment 2

[0038] The deodorant composition is in parts by weight, and includes the following raw materials: 60 parts of ultra-high fluidity thermoplastic elastomers, 40 parts of zeolite powder, 4 parts of stearic acid, 0.7 parts of dioctyl sodium dibutyrate, 12 0.3 parts of sodium alkyl sulfate, 10 parts of medical stone, 15 parts of cactus plant extract, 6 parts of sawdust, 8 parts of negative ion powder, 5 parts of boric acid, and 5 parts of saponins.

[0039] S1: Put the ultra-high fluidity thermoplastic elastomer, zeolite powder, stearic acid, and wood chips into a mixer at a temperature of 130°C and a stirring speed of 250r / min and stir for 8 minutes to obtain a mixture A;

[0040] Before the step of preparing the mixture A in the above-mentioned step S1, grind the zeolite powder, medical stone, wood chips, and saponins to 450 mesh;

[0041] S2: Add medical stone, cactus plant extract, negative ion powder, boric acid, saponin, sodium dioctyl sulfonate dibutyrate, and sodium lauryl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com