Multi-element biological organic soil improved fertilizer and preparing method thereof

An organic soil and improved technology, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of bio-organic parts, can solve problems such as people's health, hidden dangers of rural economic development, harmful residues of chemical fertilizers in farming, and loss of nutrients. Reduce the content of heavy metal ions, improve the utilization rate of fertilizer, and promote the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

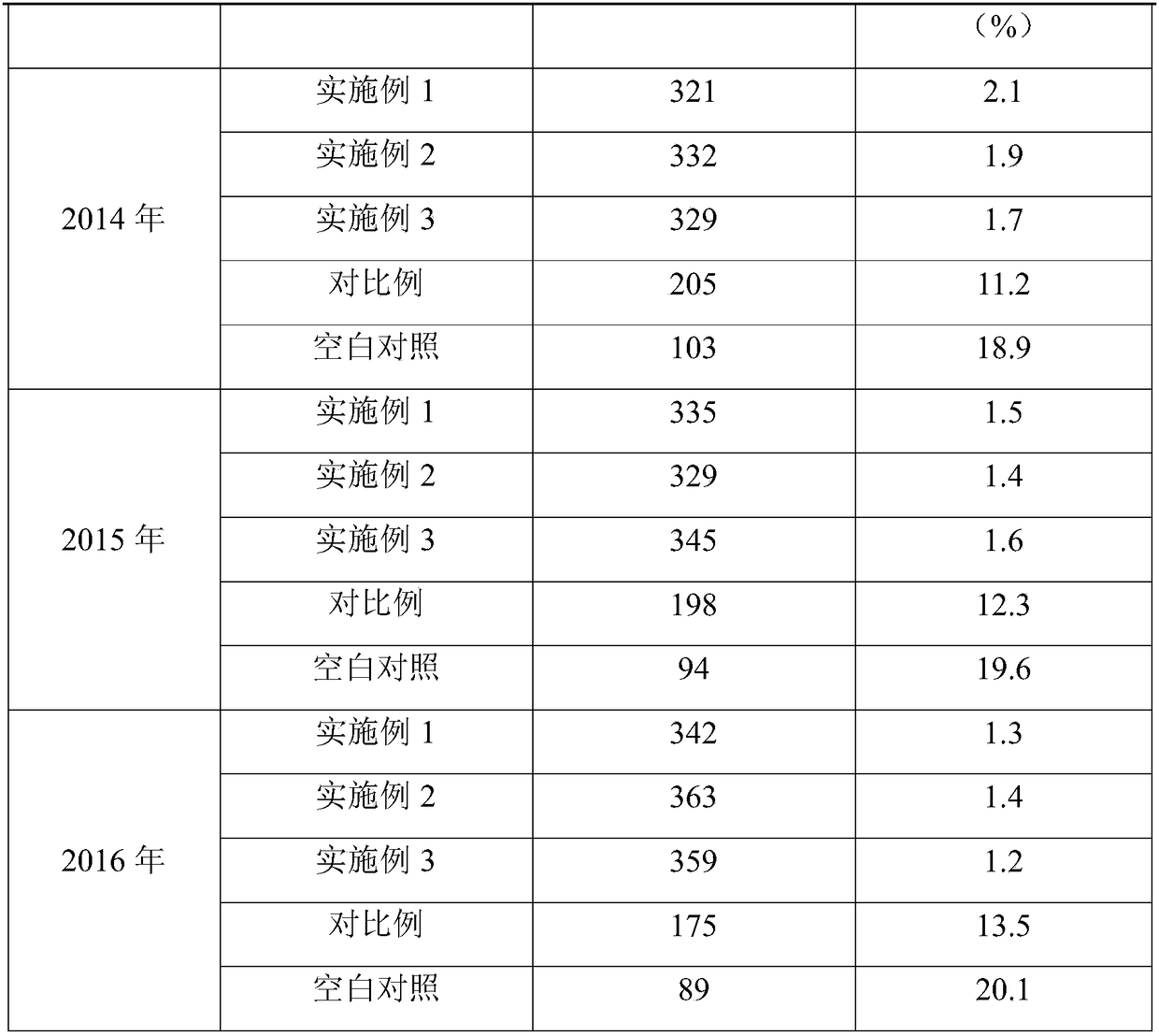

Examples

Embodiment 1

[0018] A multi-element bio-organic soil improvement fertilizer, which is made of the following raw materials in parts by weight: 80 parts of urea, 30 parts of monoammonium phosphate, 20 parts of potassium chloride, 100 parts of poultry slaughter waste, and 30 parts of humic acid , 20 parts of expanded perlite, 1 part of compound microbial agent, 60 parts of plant straw, 10 parts of potassium fulvic acid, 1 part of copper sulfate, 1 part of ferrous sulfate, 0.05 parts of zinc ion-porphyrin nanocomplex, nano 1 part of titanium dioxide powder.

[0019] The preparation method of above-mentioned fertilizer is as follows:

[0020] 1) 10ml 1mol / L zinc acetate solution and 1.5ml 0.05mmol / L acetic acid solution of tetrapyridine porphyrin were added to the reaction flask at room temperature and mixed and stirred for 24 hours to obtain the zinc ion-porphyrin nanocomplex, spare;

[0021] 2) After activating Bacillus circulans and Phanerochaete chrysosporium, culture them in liquid seed ...

Embodiment 2

[0025] A multi-element bio-organic soil improvement fertilizer, which is made of the following raw materials in parts by weight: 120 parts of urea, 50 parts of monoammonium phosphate, 40 parts of potassium chloride, 200 parts of poultry slaughter waste, and 50 parts of humic acid , 40 parts of expanded perlite, 5 parts of compound microbial agent, 150 parts of plant straw, 20 parts of potassium fulvic acid, 5 parts of copper sulfate, 5 parts of ferrous sulfate, 1 part of zinc ion-porphyrin nanocomplex, nano 5 parts of titanium dioxide powder.

[0026] The preparation method of above-mentioned fertilizer is as follows:

[0027] 1) 10ml 1mol / L zinc acetate solution and 1.5ml 0.05mmol / L acetic acid solution of tetrapyridine porphyrin were added to the reaction flask at room temperature and mixed and stirred for 24 hours to obtain the zinc ion-porphyrin nanocomplex, spare;

[0028] 2) After activating Bacillus circulans and Phanerochaete chrysosporium, culture them in liquid see...

Embodiment 3

[0032] A multi-element bio-organic soil improvement fertilizer, which is made of the following raw materials in parts by weight: 100 parts of urea, 40 parts of monoammonium phosphate, 30 parts of potassium chloride, 150 parts of poultry slaughter waste, and 40 parts of humic acid , 30 parts of expanded perlite, 3 parts of compound microbial agent, 90 parts of plant straw, 15 parts of potassium fulvic acid, 3 parts of copper sulfate, 3 parts of ferrous sulfate, 0.5 parts of zinc ion-porphyrin nanocomplex, nano 2 parts of titanium dioxide powder.

[0033] The preparation method of above-mentioned fertilizer is as follows:

[0034] 1) 10ml 1mol / L zinc acetate solution and 1.5ml 0.05mmol / L acetic acid solution of tetrapyridine porphyrin were added to the reaction flask at room temperature and mixed and stirred for 24 hours to obtain the zinc ion-porphyrin nanocomplex, spare;

[0035]2) After activating Bacillus circulans and Phanerochaete chrysosporium, culture them in liquid se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com