A kind of preparation method of glass surface porous structure

A glass surface and porous structure technology, applied in the field of glass surface treatment, can solve the problems of short life and low structural bonding force, and achieve the effect of low cost, simple and easy method, and uniform porous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention relates to a method for preparing a porous structure on a glass surface, wherein the corrosion solution is atomized to form liquid droplets to corrode the glass, specifically comprising the following steps:

[0023] 1) Pretreatment of the glass surface: the glass surface is cleaned with a cleaning solution and dried;

[0024] 2) Atomized corrosion treatment: place the glass after step 1) in the mist atmosphere formed by the atomized corrosive liquid or use a pipeline to spray the atomized liquid on the glass surface, and contact the glass surface to treat the glass surface carry out corrosion reactions;

[0025] 3) post-corrosion treatment: the corroded glass after step 2) is ultrasonically cleaned with deionized water, cleaning solution and deionized water, and then dried to obtain glass with a porous structure on the surface.

[0026] The pretreatment in step 1) includes: cleaning and drying. Further preferably, ultrasonically clean with acetone and al...

Embodiment 1

[0037] The preparation method of the glass surface porous structure of the present embodiment comprises the following steps:

[0038] 1) Pretreatment of the glass surface: Put the ordinary silicate glass sheet with a thickness of 11±1mm and a size of 25mm×25mm into acetone, ethanol, and DI for 20 minutes, and then dry it with nitrogen at room temperature to remove Organic and inorganic pollutants on the surface of glass sheets;

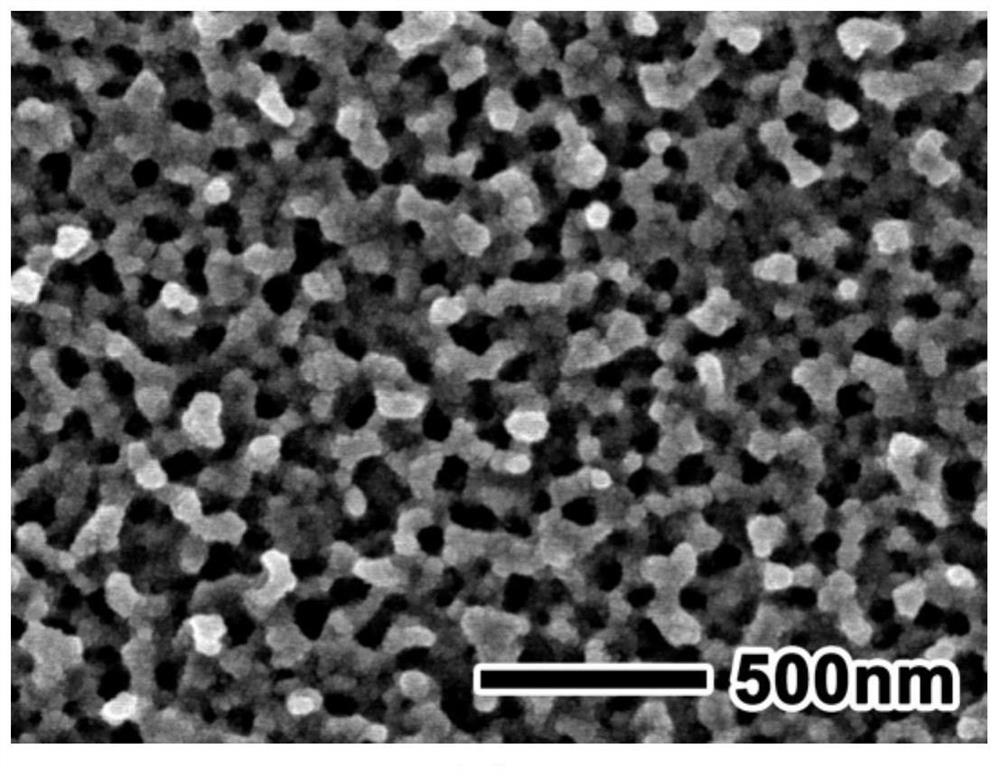

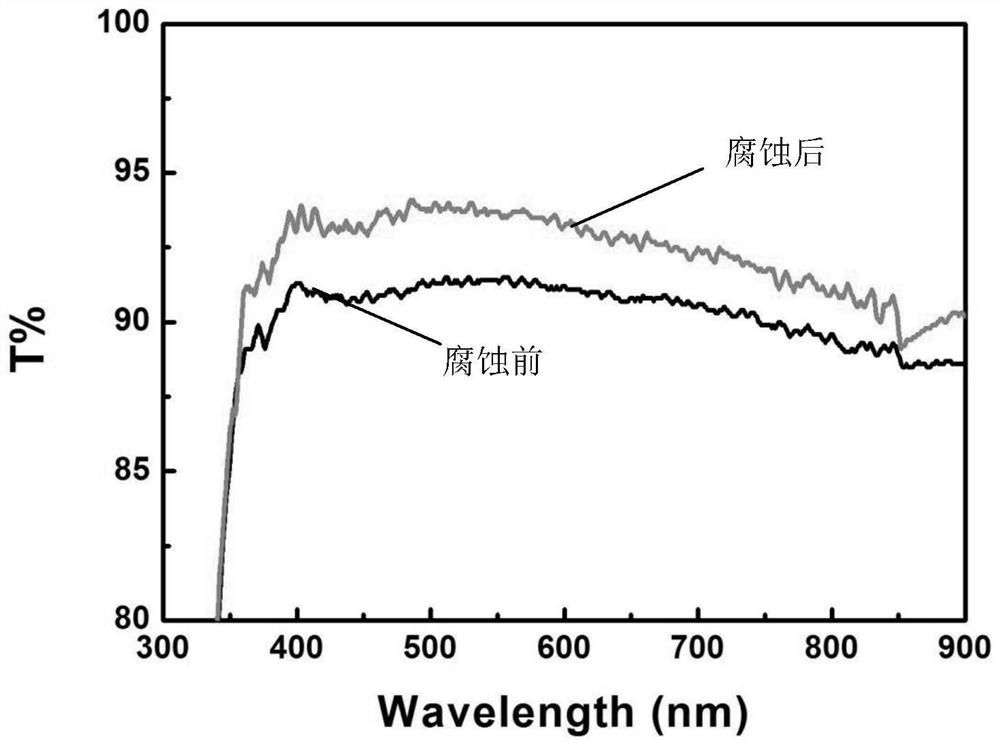

[0039] 2) Atomization corrosion treatment: Place the pretreated glass sheet horizontally in the PTFE pipe, put the corrosive liquid into the compressed air atomizer, and pass the generated corrosive acid mist into the front end of the pipe for corrosion , the diameter of the droplets obtained after atomization is 3.5 μm, and the mist volume of the corrosive acid mist is controlled as: 0.2ml / min. Heat the pipe so that the temperature reaches 80°C, ie the second preset temperature is 80°C. The corrosion solution is a mixed solution of HF and DI, and t...

Embodiment 2

[0044] The preparation method of the glass surface porous structure of the present embodiment comprises the following steps:

[0045] 1) Pretreatment of the glass surface: Put the ordinary silicate glass sheet with a thickness of 11±1mm and a size of 25mm×25mm into acetone, ethanol, and DI for 20 minutes, and then dry it with nitrogen at room temperature to remove Organic and inorganic pollutants on the surface of glass sheets;

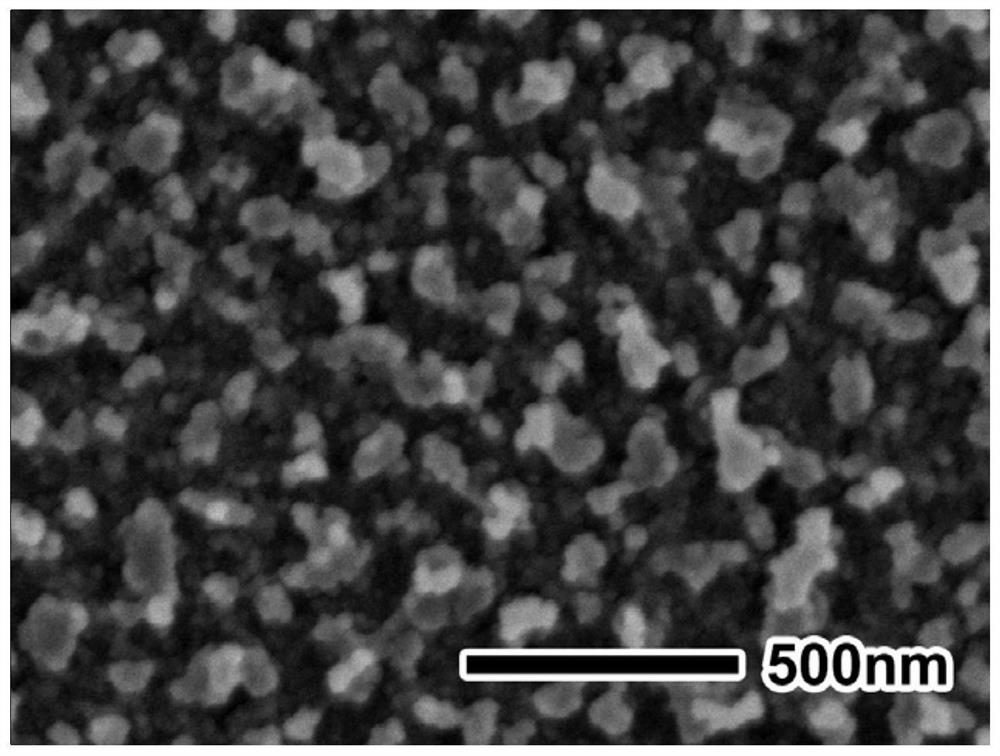

[0046] 2) Atomization corrosion treatment: place the pretreated glass sheet horizontally in a polytetrafluoroethylene container, put the corrosive liquid into a compressed air atomizer, and pass the generated corrosive acid mist into the container for corrosion , the median diameter of the droplets obtained after atomization is 3.5 μm, and the mist volume of the corrosive acid mist is controlled as: 0.2ml / min. Heat the bottom of the container so that the temperature reaches 60°C, even if the second predetermined temperature is 60°C, the reaction time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com