A high-strength carrier material for sewage treatment and its preparation method

A carrier material and sewage treatment technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, anaerobic digestion treatment, etc., can solve the problems of inappropriate porosity, small specific surface area, short life, etc., to achieve Appropriate porosity, high strength and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation of the above-mentioned carrier material also includes:

[0020] Add activated clay and activated carbon together with hydroxyethyl methacrylate and water and mix evenly, then add porogen and stir quickly, then add crosslinking agent and catalyst, and proceed to the subsequent steps.

[0021] In the preparation of the above-mentioned carrier material, adding the uniformly mixed material into the mold for heat treatment is as follows: adding the uniformly mixed material into the mold and sealing it, and heating at a temperature of 60-80°C for 2-12 hours;

[0022] The water washing process is as follows: soak the pelletized material in deionized water for 7 days, and replace the deionized water every 24 hours.

[0023] The embodiment of the present invention also provides a method for preparing a high-strength carrier material for sewage treatment, which is used to prepare the above-mentioned high-strength carrier material, comprising the following steps: ...

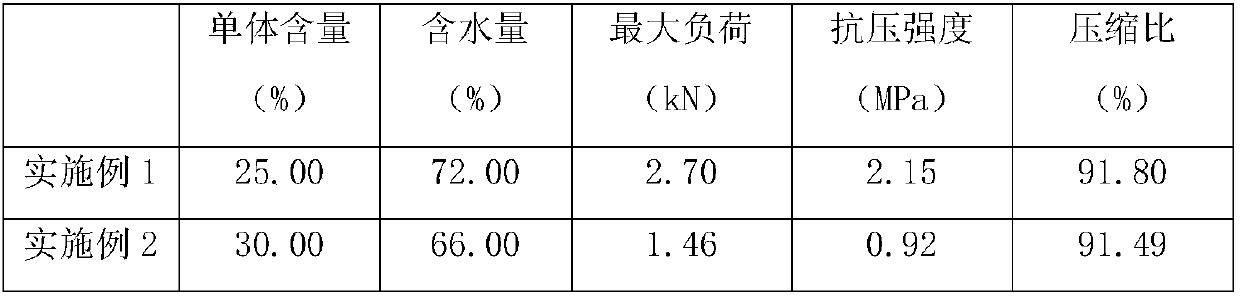

Embodiment 1

[0041] This embodiment provides a high-strength carrier material for sewage treatment, which is a biological carrier, which consists of: 25 g of hydroxyethyl methacrylate, 1 g of activated clay, 1 g of activated carbon, 0.25 g of sodium lauryl sulfate, 0.25 g of N,N'-methylenebisacrylamide, 0.25 g of ammonium persulfate, 0.25 g of sodium bisulfite, and 72 g of water.

Embodiment 2

[0043] This embodiment provides a high-strength carrier material for sewage treatment, which is a biological carrier, which consists of: 30g of hydroxyethyl methacrylate, 0.5g of activated clay, 2g of activated carbon, 0.3g of dodecanol, N, 0.3 g of N'-methylenebisacrylamide, 0.45 g of ammonium persulfate, 0.45 g of sodium bisulfite, and 66 g of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com