High frequency induction heating assisted cold spraying deposition metal 3D printing method and device

A high-frequency induction heating, 3D printing technology, applied in the direction of additive processing, can solve the problems of high equipment cost, expensive laser system, restrict promotion and application, etc., achieve simple equipment, low maintenance and use costs, improve heating The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

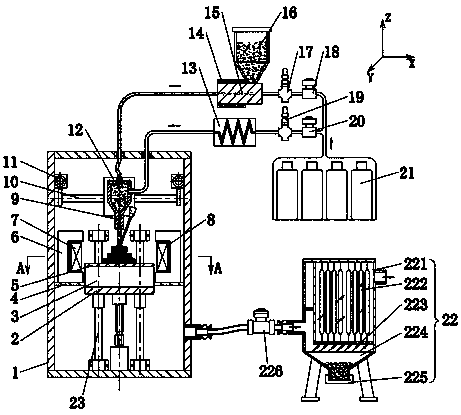

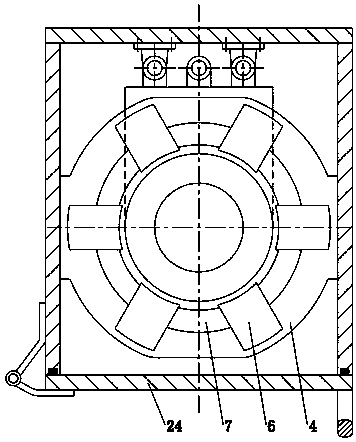

[0045] Such as figure 1 and figure 2 As shown, it is a high frequency induction heating assisted cold spray deposition metal 3D printing method, including:

[0046] Step 1 Preparation

[0047] ① Put the pure copper metal powder for 3D printing into the metal powder storage tank 16 of the 3D printer;

[0048] Pack the bottled compressed working gas into the gas supply device 21;

[0049] ②Put the printing tray 5 on the printing tray mounting seat 3 in the chassis 1 and lock it. The printing tray mounting seat 3 is set on the Z-direction movement component and located in the chassis 1. Close and lock the sealing door 24 of the chassis, and the chassis 1 The exhaust port of the exhaust port communicates with the one-way valve 226 of the metal powder collecting device 22;

[0050] ③ Import the 3D model data of the parts to be printed, and perform layered slice processing on the model;

[0051] Step 2 Preprocessing

[0052] ①Open the one-way valve 226, set the pressure value...

Embodiment 2

[0071] Such as figure 1 and figure 2 As shown, it is a high frequency induction heating assisted cold spray deposition metal 3D printing method, including:

[0072] Step 1 Preparation

[0073] ① Put the aluminum metal powder used for 3D printing into the metal powder storage tank 16 of the 3D printer; put the bottled compressed working gas into the gas supply device 21;

[0074] ②Put the printing tray 5 on the printing tray mounting seat 3 in the chassis 1 and lock it. The printing tray mounting seat 3 is set on the Z-direction movement component and located in the chassis 1. Close and lock the sealing door 24 of the chassis, and the chassis 1 The exhaust port of the exhaust port communicates with the one-way valve 226 of the metal powder collecting device 22;

[0075] ③ Import the 3D model data of the parts to be printed, and perform layered slice processing on the model;

[0076] Step 2 Preprocessing

[0077] ① The one-way valve 226 is opened, the pressure value of the...

Embodiment 3

[0094] Such as figure 1 and figure 2 As shown, it is a high frequency induction heating assisted cold spray deposition metal 3D printing method, including:

[0095] Step 1 Preparation

[0096] ① Put the zinc metal powder used for 3D printing into the metal powder storage tank 16 of the 3D printer; put the bottled compressed working gas into the gas supply device 21;

[0097] ②Put the printing tray 5 on the printing tray mounting seat 3 in the chassis 1 and lock it. The printing tray mounting seat 3 is set on the Z-direction movement component and located in the chassis 1. Close and lock the sealing door 24 of the chassis, and the chassis 1 The exhaust port of the exhaust port communicates with the one-way valve 226 of the metal powder collecting device 22;

[0098] ③ Import the 3D model data of the parts to be printed, and perform layered slice processing on the model;

[0099] Step 2 Preprocessing

[0100] ① The one-way valve 226 is opened, the pressure value of the one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com