A kind of nifedipine sustained-release tablet and preparation method thereof

A technology of nifedipine and sustained-release tablets, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve problems such as difficult bioequivalence and unstudied release behavior, and achieve The effect of increasing the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] 20mg nifedipine sustained-release tablet prescription (300,000 / batch) and preparation method thereof:

[0070]

[0071] Preparation Process:

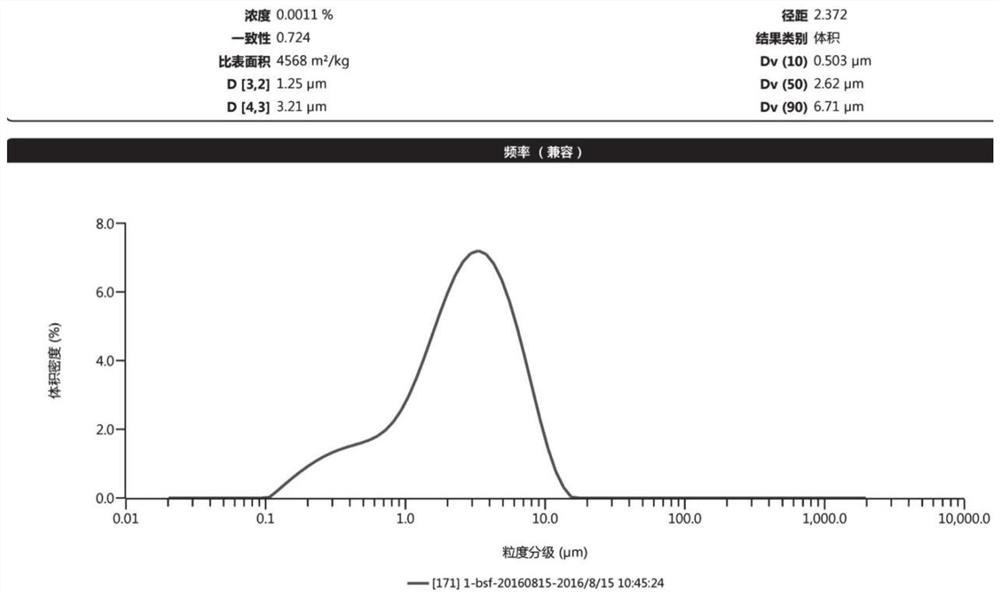

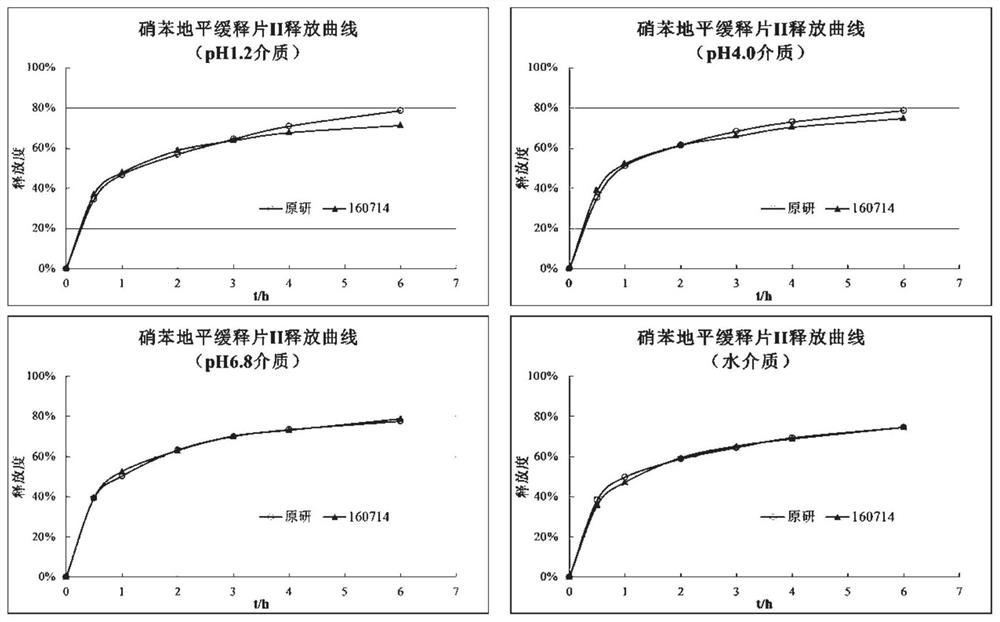

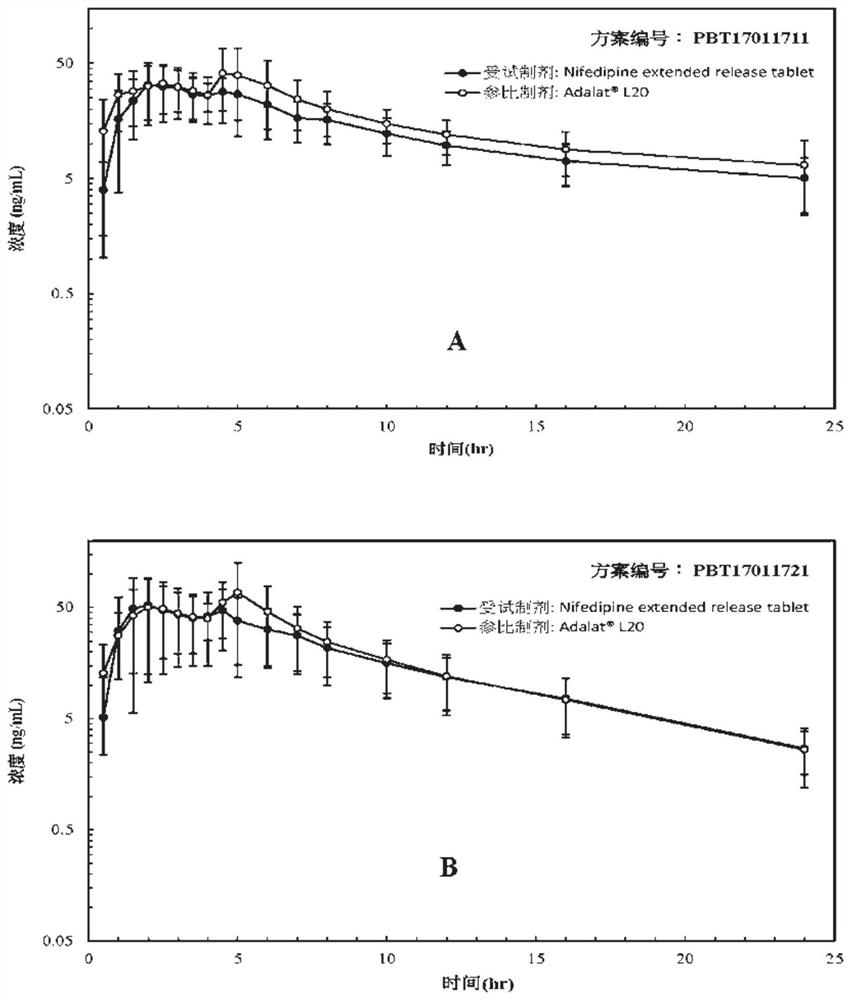

[0072] Pass the prescribed amount of microcrystalline cellulose, hypromellose, and hypromellose through an 80-mesh sieve, and control the particle size of ethyl cellulose to D 90 200 ~ 300um, standby; hypromellose, hypromellose, ethyl cellulose mixed uniformly as blocker composition; blocker composition, anhydrous calcium hydrogen phosphate and raw materials (D 90 5 ~ 10um) into the wet granulator, after stirring at speed I for 10 minutes, add microcrystalline cellulose and continue stirring for 5 minutes; add an appropriate amount of 95% ethanol to dissolve Tween 80, stir at speed I and chop at speed II during the liquid addition process 4min, out of the pan; after drying in an oven at 30°C for 1h, increase the temperature to 50°C and continue drying for 1h until the water content is lower than 3%, and granulate; add dry gr...

Embodiment 2

[0074] 20mg nifedipine sustained-release tablet prescription (300,000 / batch) and preparation method thereof:

[0075]

[0076] Preparation Process:

[0077] Pass the prescribed amount of microcrystalline cellulose, hypromellose, and hypromellose through an 80-mesh sieve, and control the particle size of ethyl cellulose to D 90 200 ~ 300um, standby; hypromellose, hypromellose, ethyl cellulose mixed uniformly as blocker composition; blocker composition, anhydrous calcium hydrogen phosphate and raw materials (D 90 5 ~ 10um) into the wet granulator, after stirring at speed I for 10 minutes, add microcrystalline cellulose and continue stirring for 5 minutes; add an appropriate amount of 95% ethanol to dissolve Tween 80, stir at speed I and chop at speed II during the liquid addition process 4min, out of the pan; after drying in an oven at 30°C for 1h, increase the temperature to 50°C and continue drying for 1h until the water content is lower than 3%, and granulate; add dry gr...

Embodiment 3

[0079] 20mg nifedipine sustained-release tablet prescription (300,000 / batch) and preparation method thereof:

[0080]

[0081] Preparation Process:

[0082] Pass the prescribed amount of microcrystalline cellulose, hypromellose, and hypromellose through an 80-mesh sieve, and control the particle size of ethyl cellulose to D 90200 ~ 300um, standby; hypromellose, hypromellose, ethyl cellulose mixed uniformly as blocker composition; blocker composition, anhydrous calcium hydrogen phosphate and raw materials (D 90 5 ~ 10um) into the wet granulator, after stirring at speed I for 10 minutes, add microcrystalline cellulose and continue stirring for 5 minutes; add an appropriate amount of 95% ethanol to dissolve Tween 80, stir at speed I and chop at speed II during the liquid addition process 4min, out of the pan; after drying in an oven at 30°C for 1h, increase the temperature to 50°C and continue drying for 1h until the water content is lower than 3%, and granulate; add dry gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com