Cloth storage tank and axial oblique-slip type high-temperature gas-liquid dyeing machine

A cloth storage tank and dyeing machine technology, applied in the field of dyeing machines, can solve the problems such as insufficient release of internal stress of synthetic fibers, limited use of horizontal cylindrical high-temperature dyeing machines, and no free relaxation space, and reduce mutual The effect of squeezing force, increasing productivity, avoiding squeezing creases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

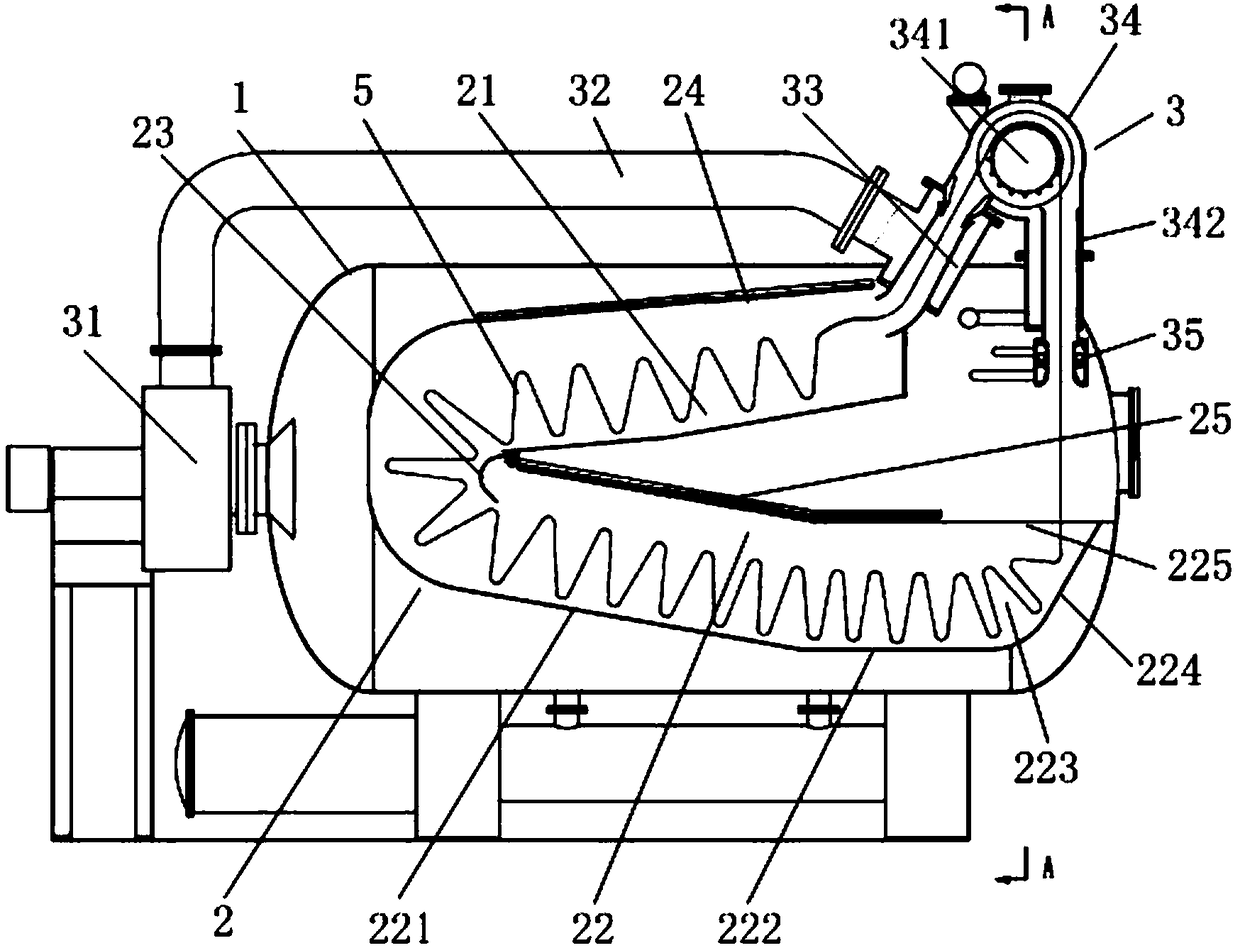

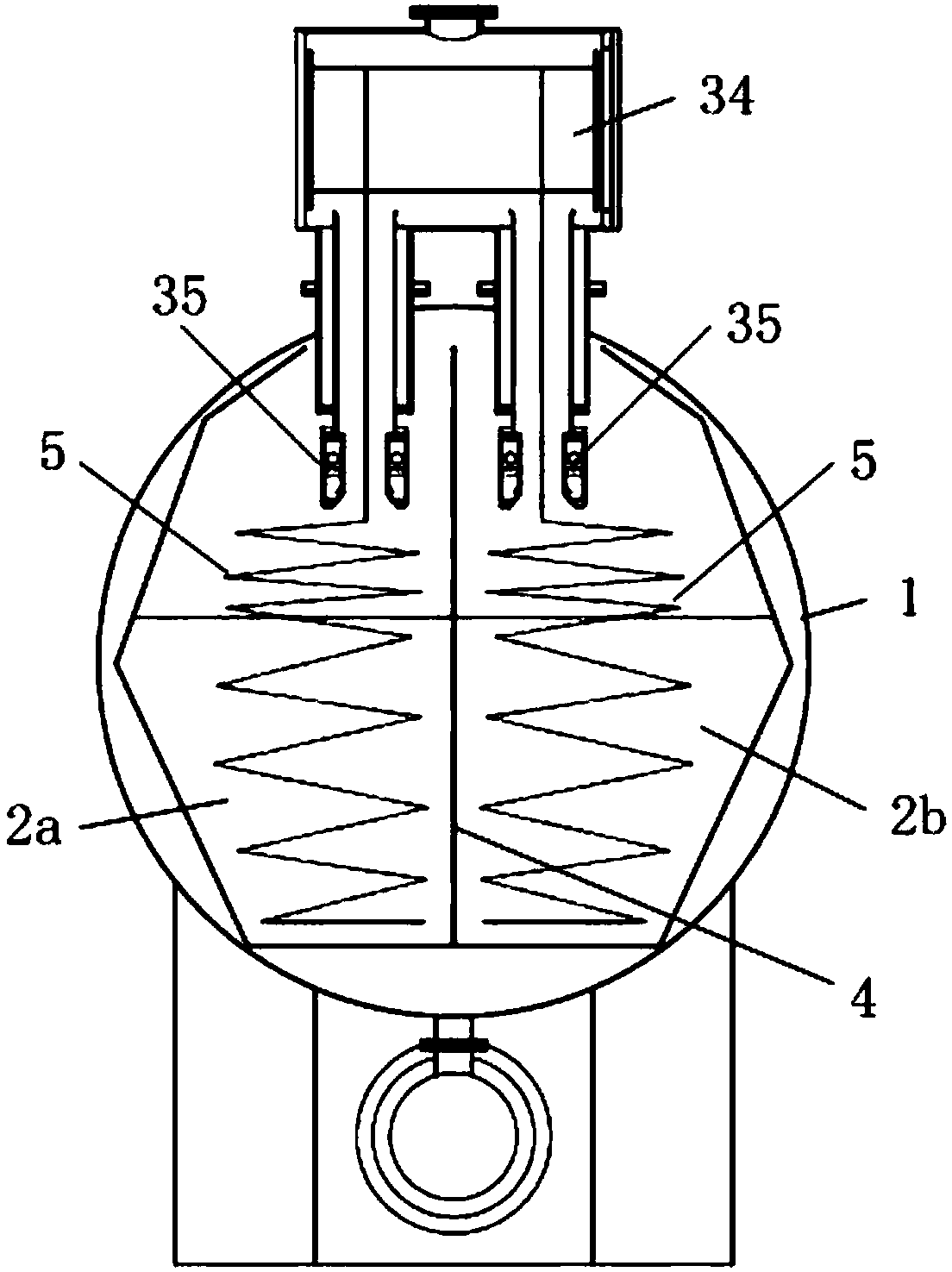

[0020] like figure 1 As shown, the first embodiment of the present invention provides an axially inclined high-temperature gas-liquid dyeing machine, including a main cylinder body 1 and a dyeing and finishing mechanism 3 for fabric dyeing and finishing. A cloth storage tank 2 is provided. The dyeing and finishing mechanism 3 includes a blower fan 31, an air duct 32, an air flow nozzle 33, a cloth lifting mechanism 34 and a front dye solution nozzle 35. The fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com