Buffer storage bottle conveying device for solid bottles in large bottle water production line

A technology for conveying devices and large bottles of water. It is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of solid bottle deformation, large installation space, and label scratches, so as to maintain uniform spacing and reduce installation space. , The effect of shortening the conveying length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

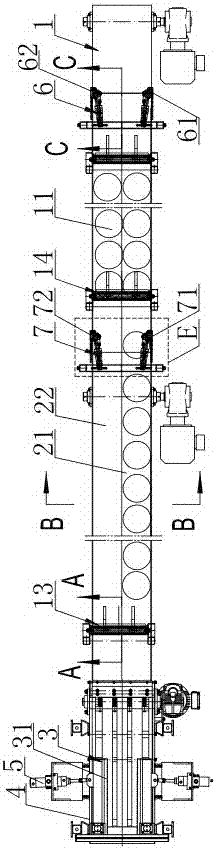

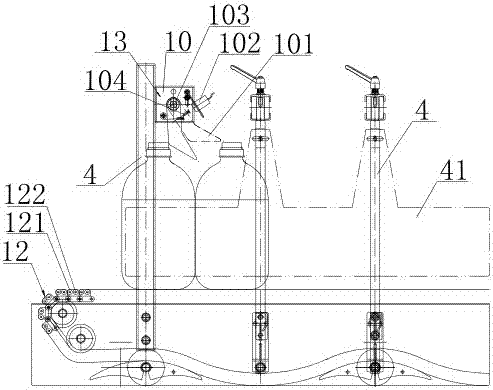

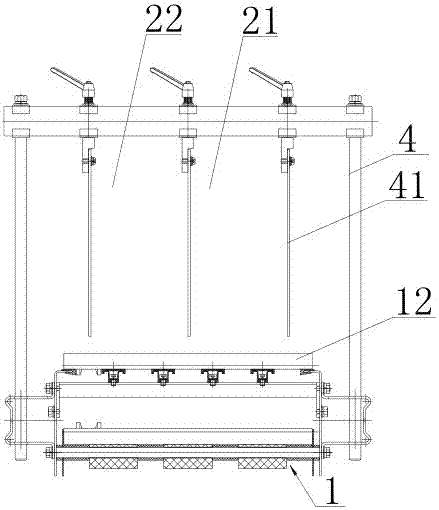

[0018] Such as figure 1 , figure 2 , image 3 As shown, the buffer storage bottle conveying device of the solid bottle in the large bottle water production line includes: a chain plate conveying mechanism 1, and the conveying chain plate 12 in the chain plate conveying mechanism 1 in the present embodiment adopts the surface laid with rotatable rollers 121 Roller chain plate, roller chain plate is a kind of conveyor chain plate commonly used in the field of transportation, each roller 121 is set on the installation shaft 122 on the chain plate mounting frame, and each roller 121 can be mounted on the corresponding Roll on shaft 122. The function of adopting the roller chain plate is that the friction between the solid bottle and the conveying chain plate is rolling friction, which can effectively reduce the friction force between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com