Method for supplying cross winding mechanisms of a spinning machine with sleeves and spinning machine

A technology for cross-winding, textile machines, used in the field of supplying bobbins and textile machines for cross-winding devices of textile machines, capable of solving difficulties, conflicts in conveying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

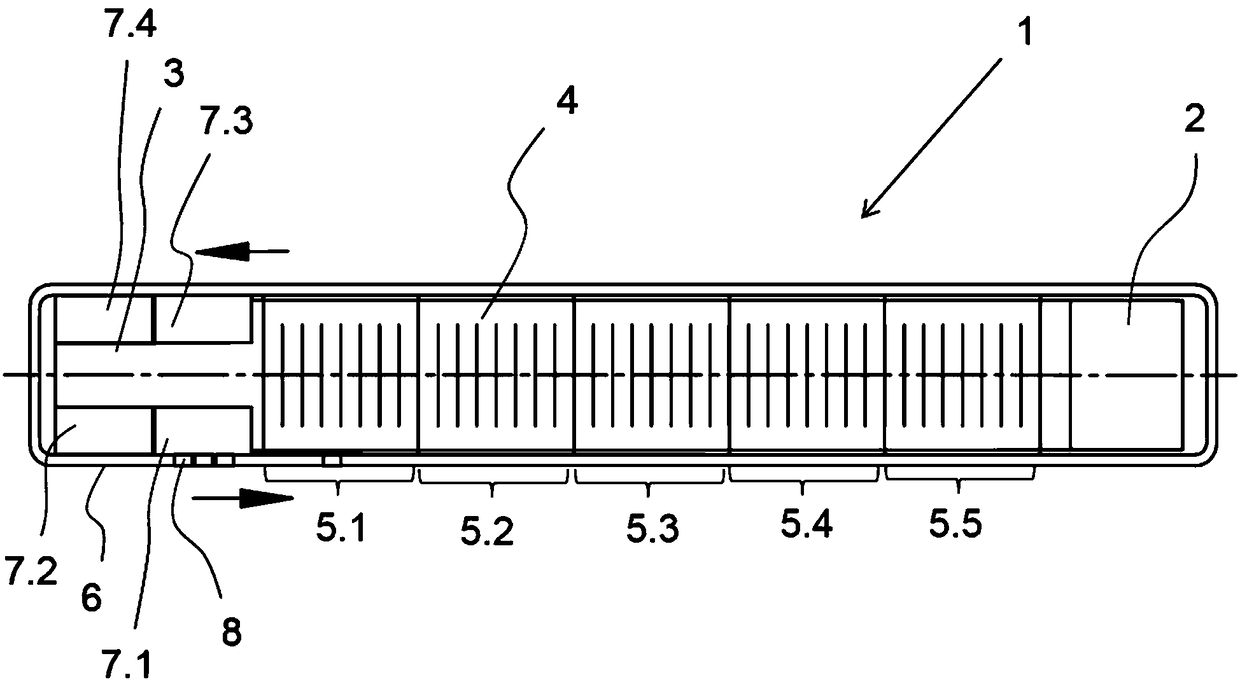

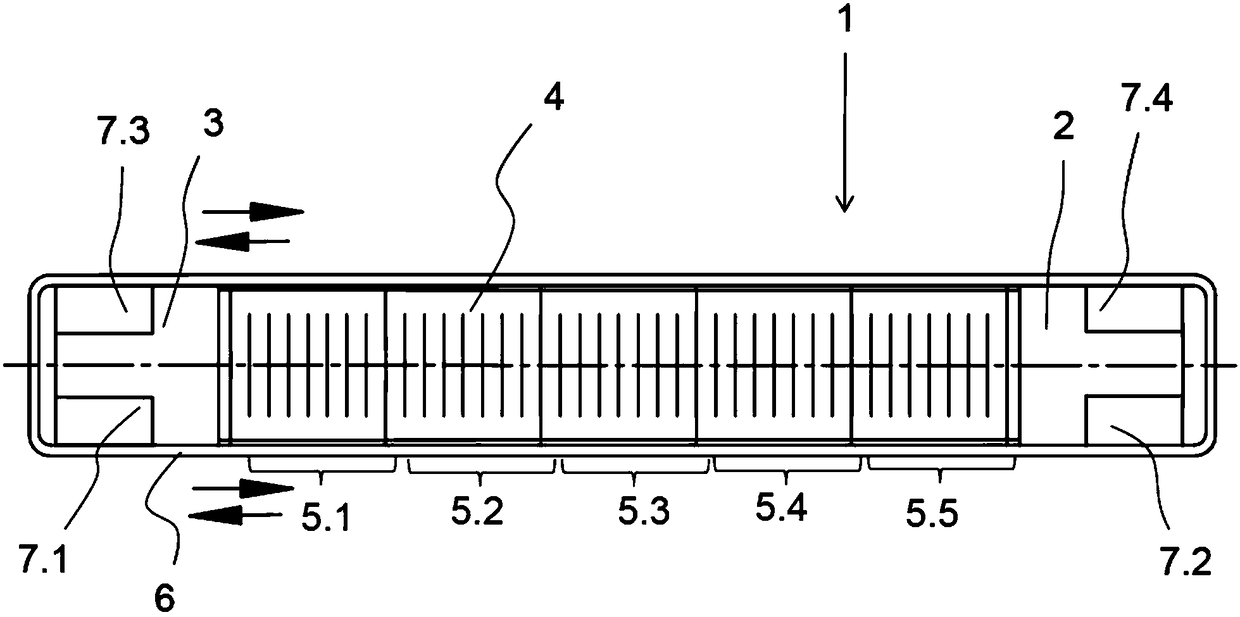

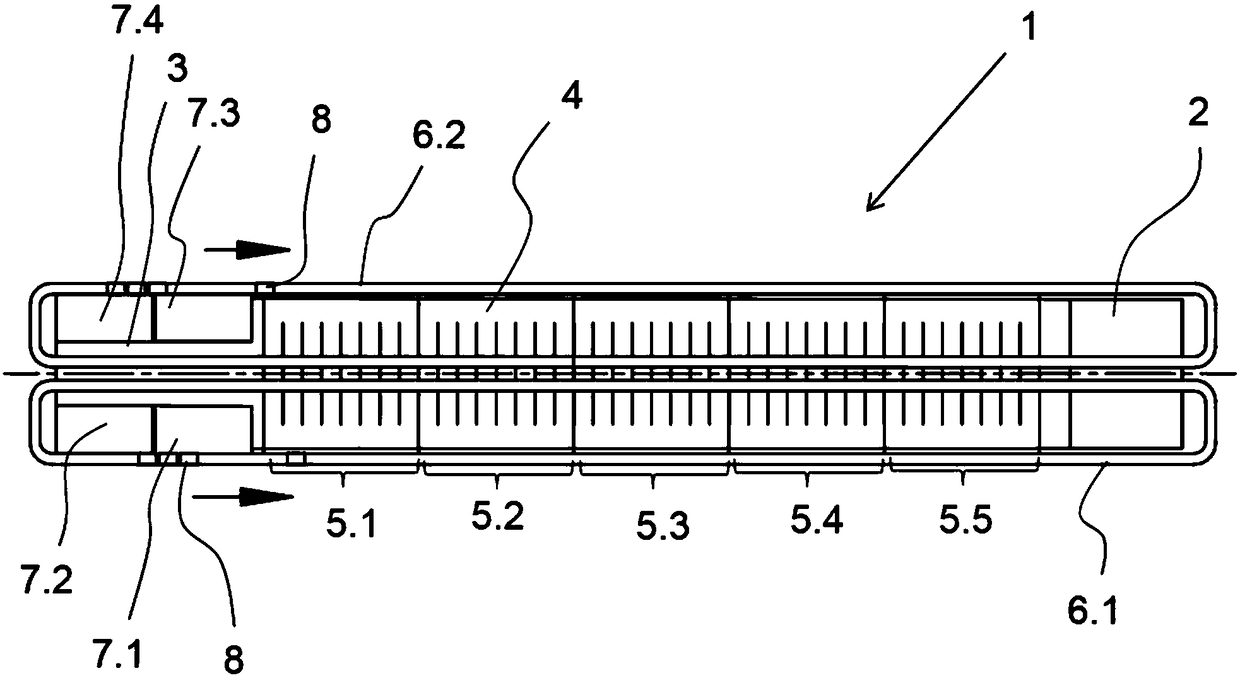

[0032] figure 1 A top view of a schematically drawn textile machine, such as an open rotor textile machine and a winding machine, is shown in . The textile machine 1 has a drive frame 2 and an end frame 3 which are each arranged at the end of the textile machine 1 . The textile machine 1 has two machine sides in the longitudinal direction, on which a plurality of crosswinding devices 4 are arranged between the drive frame 2 and the end frame 3 . For the sake of clarity, only one of the cross-winding devices 4 is provided with a reference number. A large number of cross-winding devices 4 are integrated in sections 5.1 to 5.5. In each section 5.1 to 5.5, eight cross-winding devices 4 are arranged on each machine side. In each of the cross-winding devices 4 there is provided a holder, not shown, for the bobbin 9 on which the yarn is wound in a cross-wise manner. Different bobbin types are required depending on the yarn type. This is necessary or at least helpful for later re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com