Plate stacking device and plate palletizing equipment

A board and palletizing technology, which is applied in the field of board stacking devices and board palletizing equipment, can solve the problems of long length of conveying mechanism and large space occupation, and achieve the effects of shortening the conveying length, improving efficiency and high palletizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

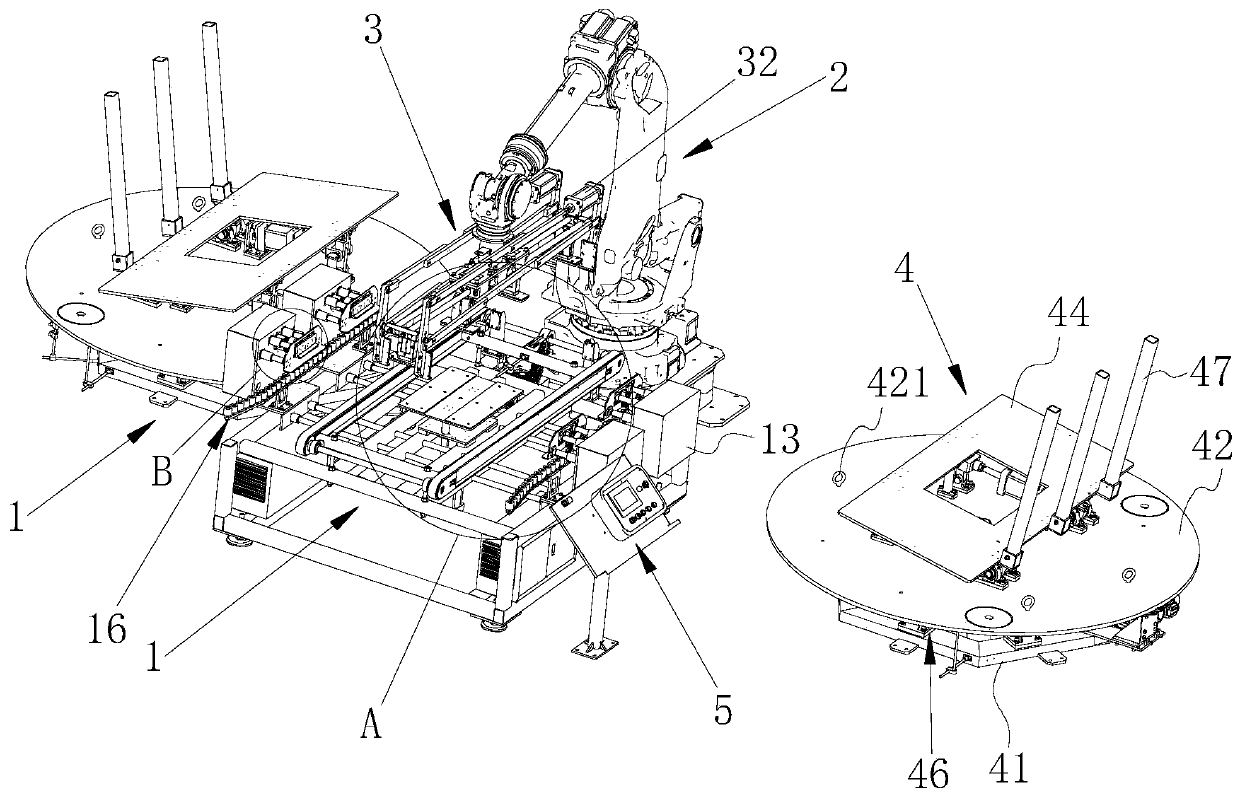

[0061] refer to figure 1 , this embodiment discloses a plate stacking device, including a plate stacking device 1, an industrial robot 2, a grabbing mechanism 3 and a plate palletizing auxiliary mechanism 4, two sets of plate auxiliary mechanisms are arranged, and the two sets of plate auxiliary mechanisms are arranged symmetrically On both sides of the plate stacking device 1 , the grabbing mechanism 3 is arranged on the end effector of the industrial robot 2 .

[0062] refer to figure 1 , the sheet palletizing device further includes a console 5, the console 5 is used to monitor or directly control the sheet stacking device 1, the industrial robot 2, the grabbing device and the sheet palletizing auxiliary mechanism 4.

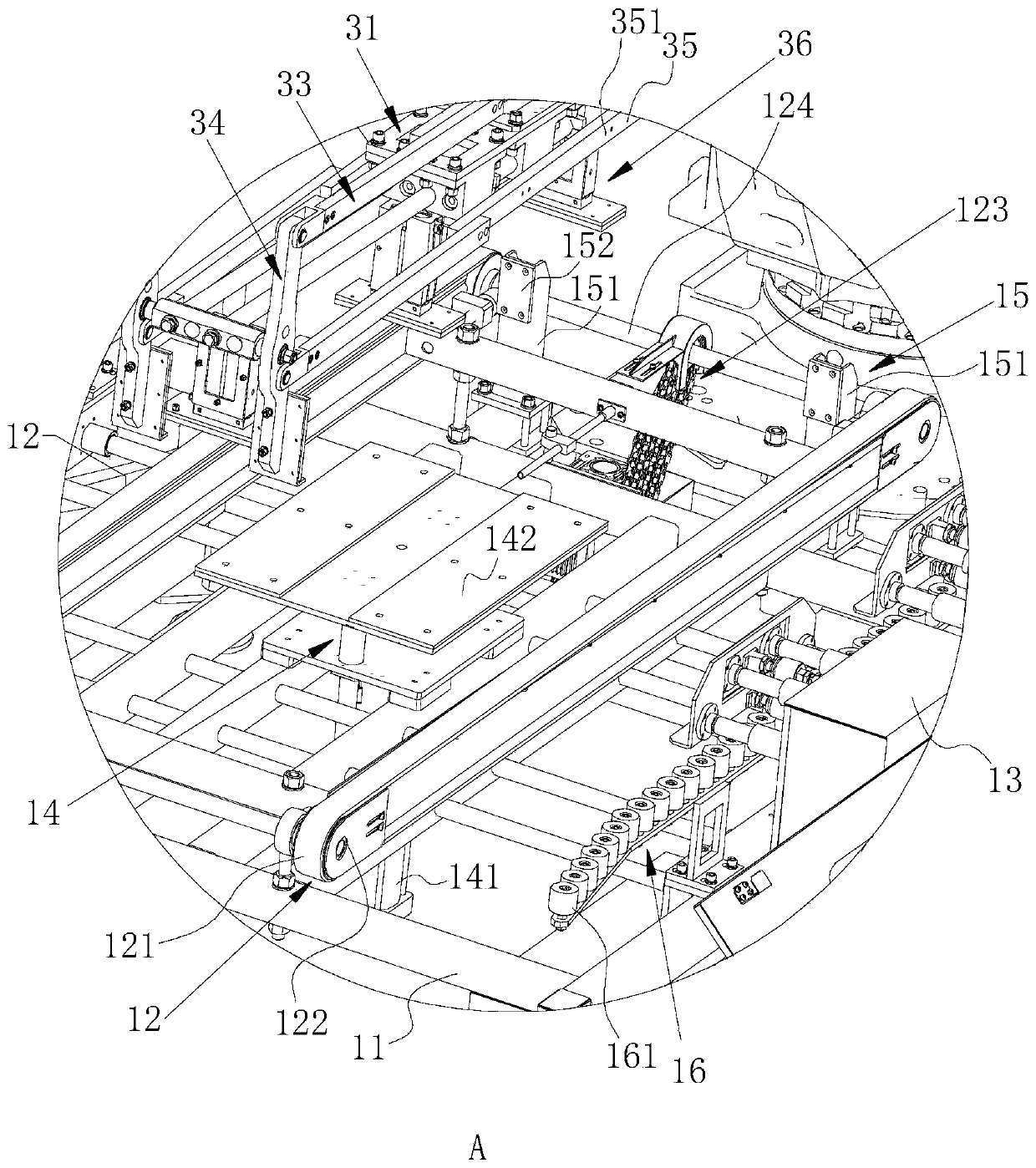

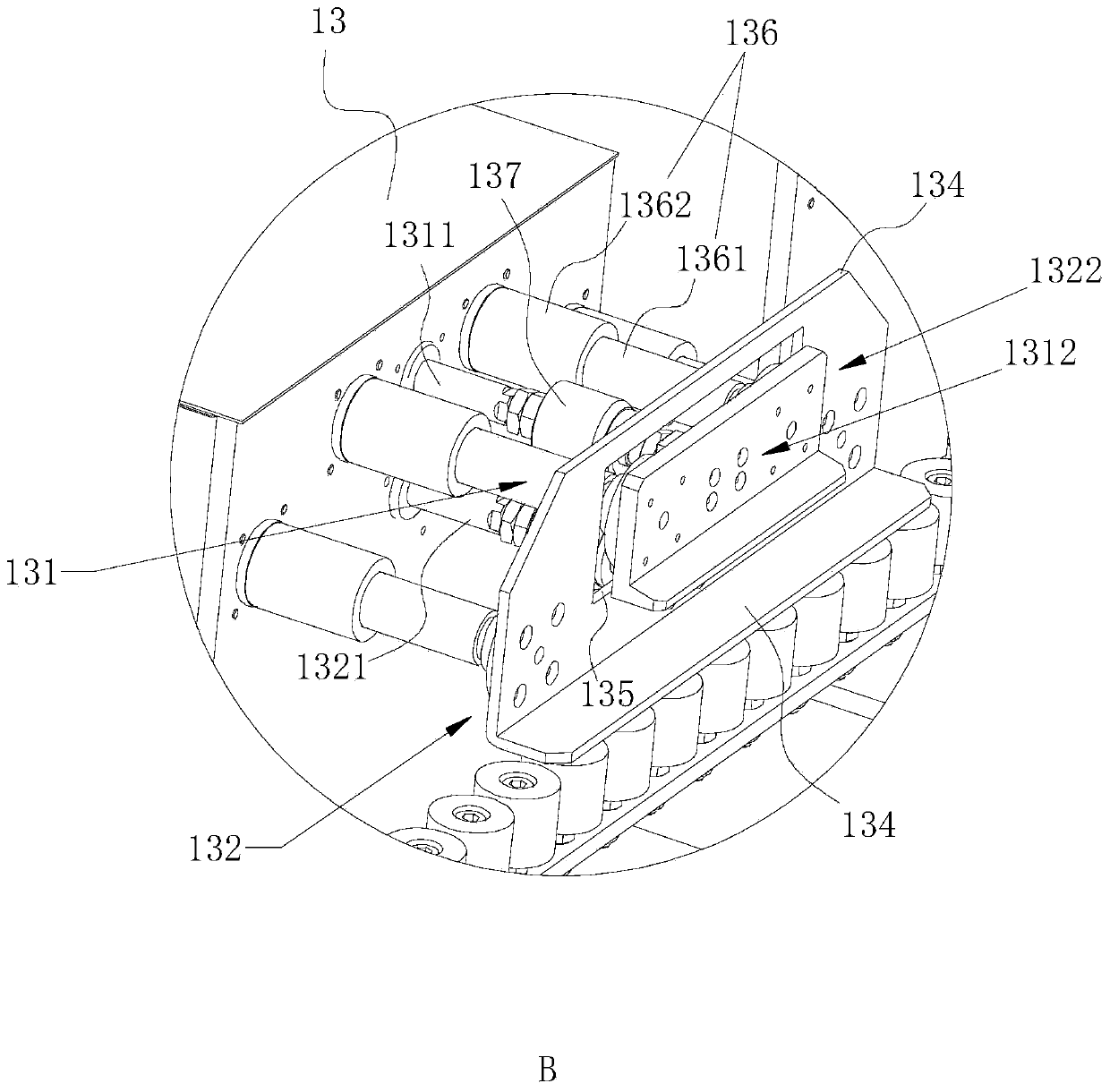

[0063] refer to figure 1 , figure 2 as well as image 3 , the plate stacking device 1 includes a stacking frame 11, a conveying mechanism 12, an alignment mechanism 13 and a jacking mechanism 14, the conveying mechanism 12 is arranged on the stacking fra...

Embodiment 2

[0098] refer to Figure 8 , this embodiment discloses another kind of plate palletizing equipment, which is based on Embodiment 1 and differs from Embodiment 1 in that the horizontal receiving portion of the first alignment plate 1312 and the horizontal receiving portion of the second alignment plate 1322 The vertical spacing is adjustable. In this embodiment, the vertical limit portion 133 of the first alignment plate 1312 is integrally formed with the horizontal receiving portion, and the horizontal support portion 134 of the second alignment plate 1322 is vertically aligned with the second alignment plate 1322. The vertical limit portion 133 of the two alignment plates 1322 is slidably connected, and the vertical limit portion 133 of the second alignment plate 1322 is provided with a chute 1331 for the horizontal supporting portion 134 to slide along the vertical direction. The second alignment plate 1322 The horizontal alignment plate of the second alignment plate 1322 is ...

Embodiment 3

[0101] refer to Figure 9 , this embodiment discloses another kind of board palletizing equipment, based on the above embodiment, and the difference from the above embodiment is that in this embodiment, a plurality of support wheels 461 are set in the direction that the rollers 4612 face downward, supporting The bracket 4611 of the wheel 461 is fixed to the lower surface of the rotating platform 42. A circular guide rail 411 is horizontally arranged on the base 41. The roller 4612 abuts against the upper surface of the guide rail 411. The roller 4612 is arranged along the tangential direction of the guide rail 411, that is, the guide wheel The side of 161 and the tangential direction of guide rail 411 are arranged, and this kind of arrangement mode facilitates the installation of support wheel 461, facilitates processing and production.

[0102] refer to Figure 9 as well as Figure 10 , the palletizing auxiliary platform 44 is provided with a gear lever 47 away from the sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com