Sanitary towel washing equipment with normal pressure spraying function

A technology for washing equipment and sanitary napkins, which is applied in spraying/spraying textile material treatment, textile material carrier treatment, chemical, etc. It can solve the problems of nozzle blockage, residue, and difficulty in spraying water, etc., and achieves the convenience of soft deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

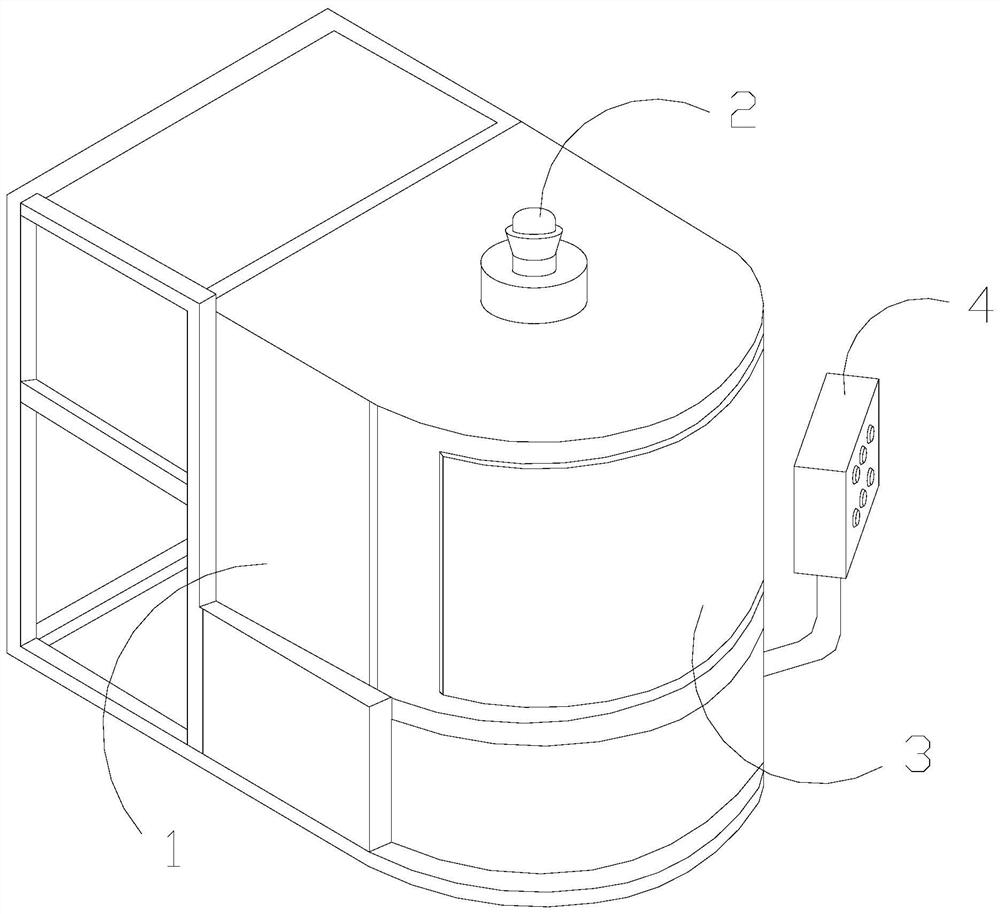

[0030] as attached figure 1 to attach Figure 6 Shown:

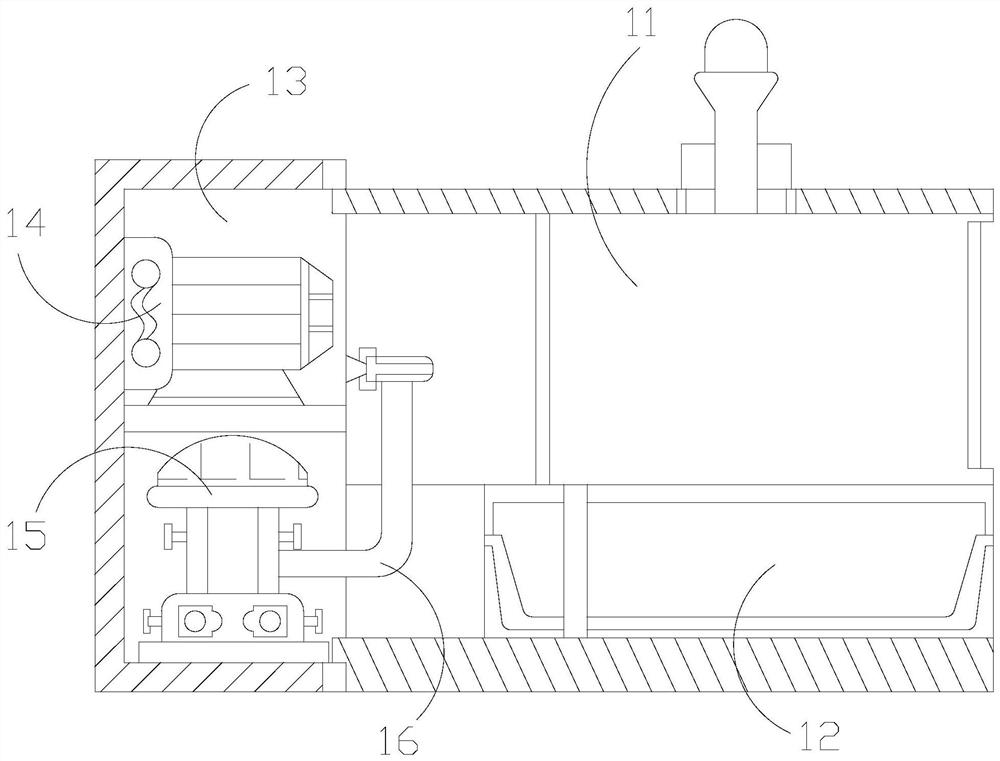

[0031] The present invention provides a sanitary napkin washing equipment with atmospheric pressure spraying, the structure of which is provided with a body 1, a water mist head 2, an observation window 3, and a control panel 4, and the water mist head 2 is installed on the top of the body 1 , the observation window 3 is integrated with the fuselage 1 and installed on its front side, and the control panel 4 is installed on the outside of the fuselage 1 .

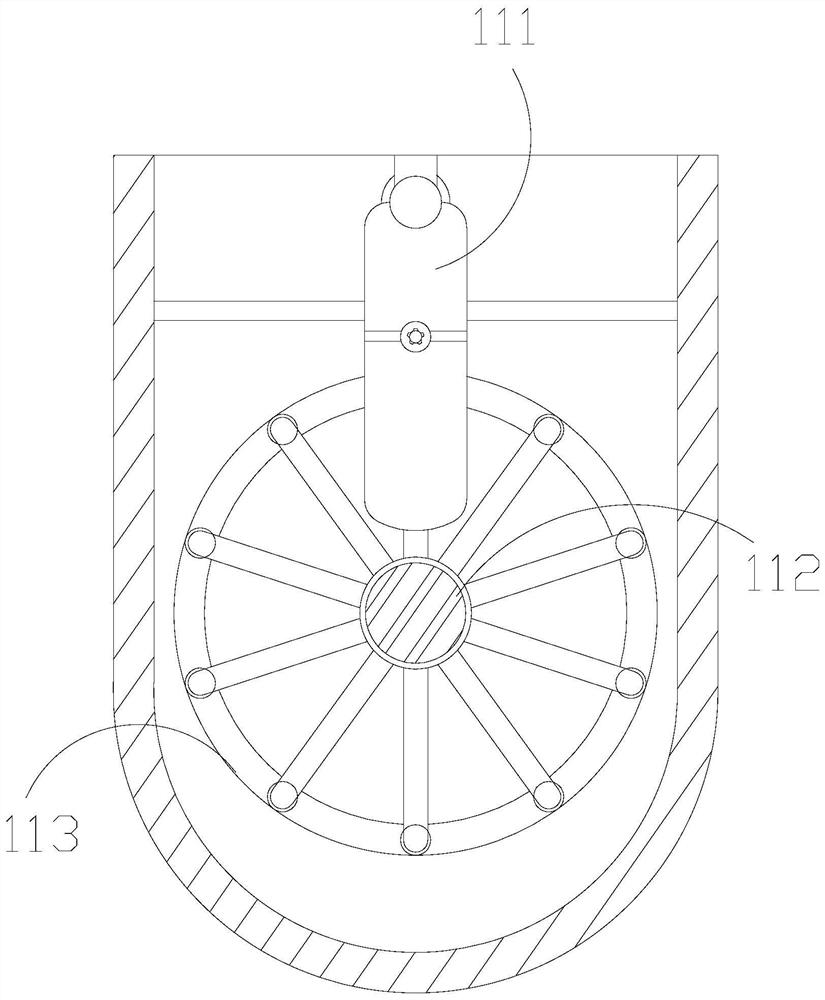

[0032] The fuselage 1 is provided with a washing chamber 11, a sump 12, a rear passage chamber 13, an air pump 14, a spray pump 15, and a water receiving pipe 16. The washing chamber 11 is connected above the sump 12, and the rear passage The chamber 13 is located at the rear side of the sump 12, the air pump 14 is embedded and installed above the interior of the rear passage chamber 13, the spray pump 15 is located below the air pump 14, and the water receiving pipe...

Embodiment 2

[0039] as attached Figure 8 to attach Figure 9 Shown:

[0040] Wherein, the corner side plate b5 is provided with a solid plate b51, a branch flow path b52, and a semicircular side cavity b53. The solid plate b51 and the corner side plate b5 are of an integrated structure, and the branch flow path b52 is arranged through the solid plate b51. At adjacent positions, the semicircular side chamber b53 and the branch flow path b52 are integrated structures and are arranged on both inner sides of the branch flow path b52. And it is arranged on the opposite side, the branch flow path b52 increases the flow channel of water, so that the solid plate b51 has more power to swing, and the semicircular side cavity b53 is used for temporary storage of water, which can make the solid plate b51 swing, and there is an external force to make it Do random swings.

[0041] Wherein, the brace b6 is provided with a support hinge rod b61, an anti-tough flap b62, and an inner guide flap b63. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com