Press ring device for physical vapor deposition equipment

A technology of physical vapor deposition and equipment, which is applied in the field of pressure ring devices, can solve the problems of indistinguishable alignment marks of wafers, inability to complete normal process, and inconvenient adjustment, so as to reduce sticking phenomenon, simple structure, and avoid The effect of sticky film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The invention provides a pressure ring device used in physical vapor deposition equipment.

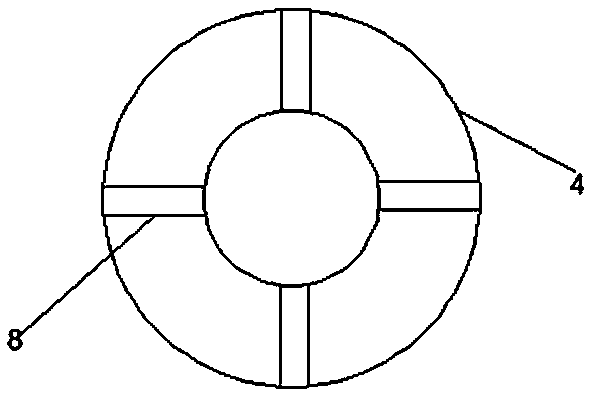

[0034] Such as Figure 1-7As shown, the pressure ring device of the physical vapor deposition equipment according to the embodiment of the present invention includes an annular body 1, and the top end of the annular body 1 is connected with a fixed platform 4, and the fixed platform 4 communicates with the annular body 1, And the bottom of the fixed table 4 is provided with a plurality of annular grooves 8, and the area enclosed between two adjacent grooves 8 is equal, the inner ring edge of the ring body 1 is fixedly connected with an extension Out of the plate 5, the number of the protruding plates 5 is four, the arc lengths formed between two adjacent protruding plates 5 are equal, and two adjacent protruding plates 5 are provided with There is a protruding platform 7, wherein, the protruding platform 7 and the extension plate 5 are all parallel to the plane of the annular b...

Embodiment 2

[0043] The protruding plate, the protruding platform and the annular body are integrally formed, and a new material is used; the new material is prepared according to the following process:

[0044] 1) According to weight percentage, the ratio of each raw material is as follows: Mn: 1.01; Ti: 0.71; Si: 0.43; Ni: 0.16; Cr: 0.12; B: 0.08; Co: 0.07; Zn: 0.05; : 0.005; the balance is Al;

[0045] 2) Put Al in No. 1 crucible A, under the protection of argon, heat up to 750°C at a rate of 5°C / S to obtain a melt; take Mn, Ti, Si, Ni, Cr, B, Co, Zn , Nb and Mo were placed in the No. 2 crucible, and the temperature was raised to 400°C at a heating rate of 2°C / S, and then argon was introduced for protection, and the temperature was continued to be raised to 750°C at a rate of 2°C / S, and kept for 10 minutes; Mix the materials in No. 1 crucible and No. 2 crucible, raise the temperature to 850°C, and refine for 3 minutes; then use a die-casting machine to die-cast it into the mold, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com