Road and bridge special concrete and preparation method thereof

A technology for concrete, roads and bridges, applied in clay preparation devices, chemical instruments and methods, cement mixing devices, etc., can solve problems such as water permeability reduction, affecting the quality and service life of roads and bridges, strength uniformity, pavement compressive strength not meeting requirements, etc. , to reduce permeability, enhance agglomeration performance, and prevent cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of special concrete for road and bridge, concrete steps are as follows:

[0036] (1) 42kg of crushed stone and 8kg of discarded broken glass slag are pulverized into particles with a particle size less than 1.5-2cm, and then 33kg of fine river sand is added and mixed evenly to obtain a mixed aggregate;

[0037] (2) Grind 11kg of waste slag, 5kg of white vermiculite, 3kg of volcanic rock and 12kg of fly ash until the particle size is less than 0.2cm for later use, add 19kg of cement and 17kg of water into the high-efficiency mixing container, stir and mix evenly, and then add 0.2kg Weather-resistant filler, 0.2kg potassium titanate spar, 1,3kg water reducer, 2.6kg silicon powder and 0.1kg solidified corrosion inhibitor, mixed at high speed for 3-5min, then added crushed waste slag, white vermiculite, volcanic stone and The fly ash is stirred and mixed evenly to obtain a bonding enhancing component;

[0038] (3) Add the bonding enhancement co...

Embodiment 2

[0046] A kind of preparation method of special concrete for road and bridge, concrete steps are as follows:

[0047] (1) 47kg of crushed stones and 12kg of discarded glass cullets are pulverized into particles with a particle size less than 1.5-2cm, and then 38kg of fine river sand is added and mixed evenly to obtain a mixed aggregate;

[0048] (2) Grind 15kg of waste slag, 7kg of white vermiculite, 7kg of volcanic rock and 15kg of fly ash until the particle size is less than 0.2cm for later use, add 23kg of cement and 21kg of water into the high-efficiency mixing container, stir and mix evenly, and then add 0.4kg Weather-resistant filler, 0.3kg potassium titanate spar, 1.7kg water reducer, 3.2kg silicon powder and 0.3kg solidified corrosion inhibitor, stir and mix at high speed for 3-5min, then add crushed waste slag, white vermiculite, volcanic stone and powder Stir and mix the coal ash evenly to obtain a bonding enhancing component;

[0049] (3) Add the bonding enhancement...

Embodiment 3

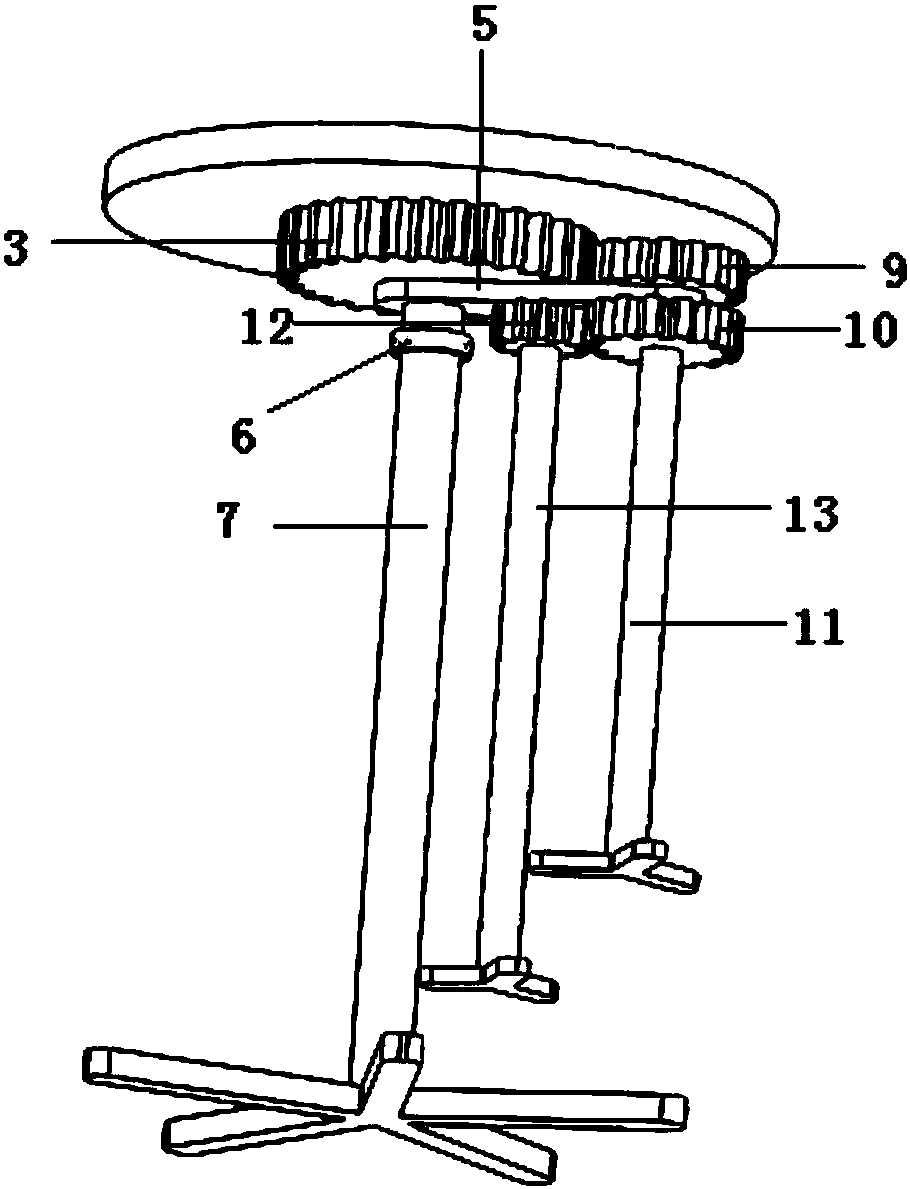

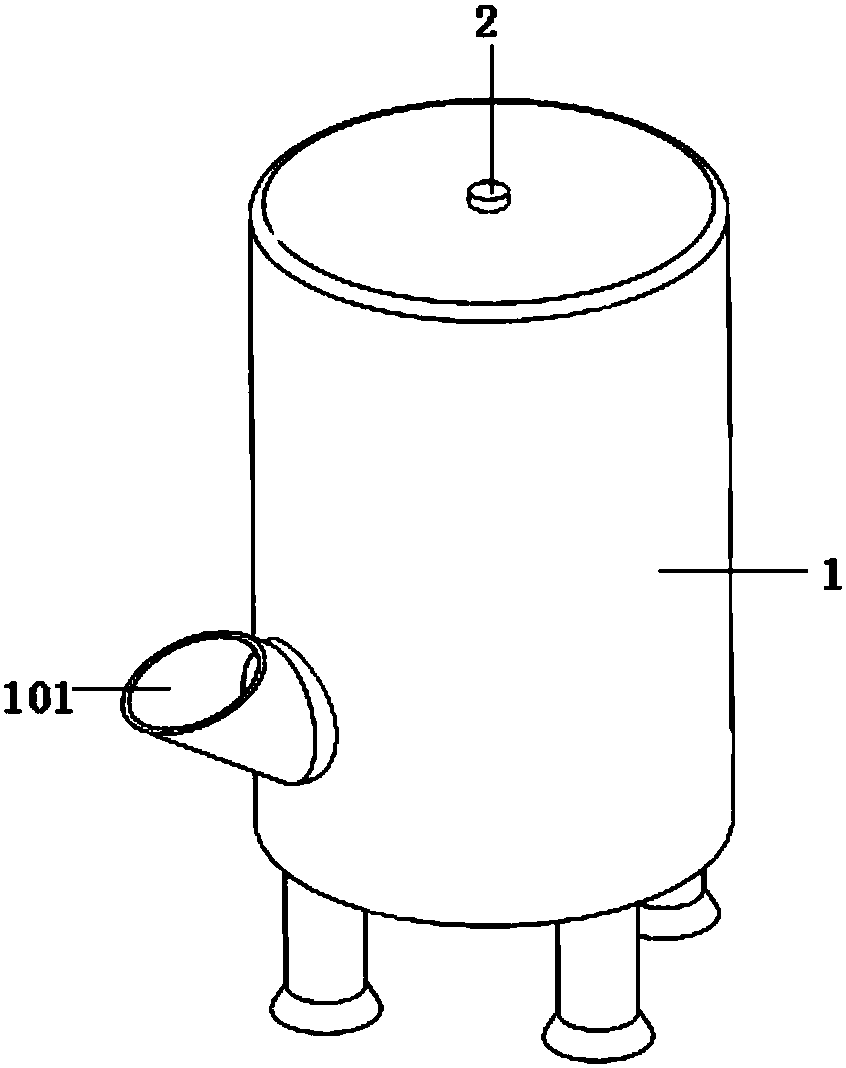

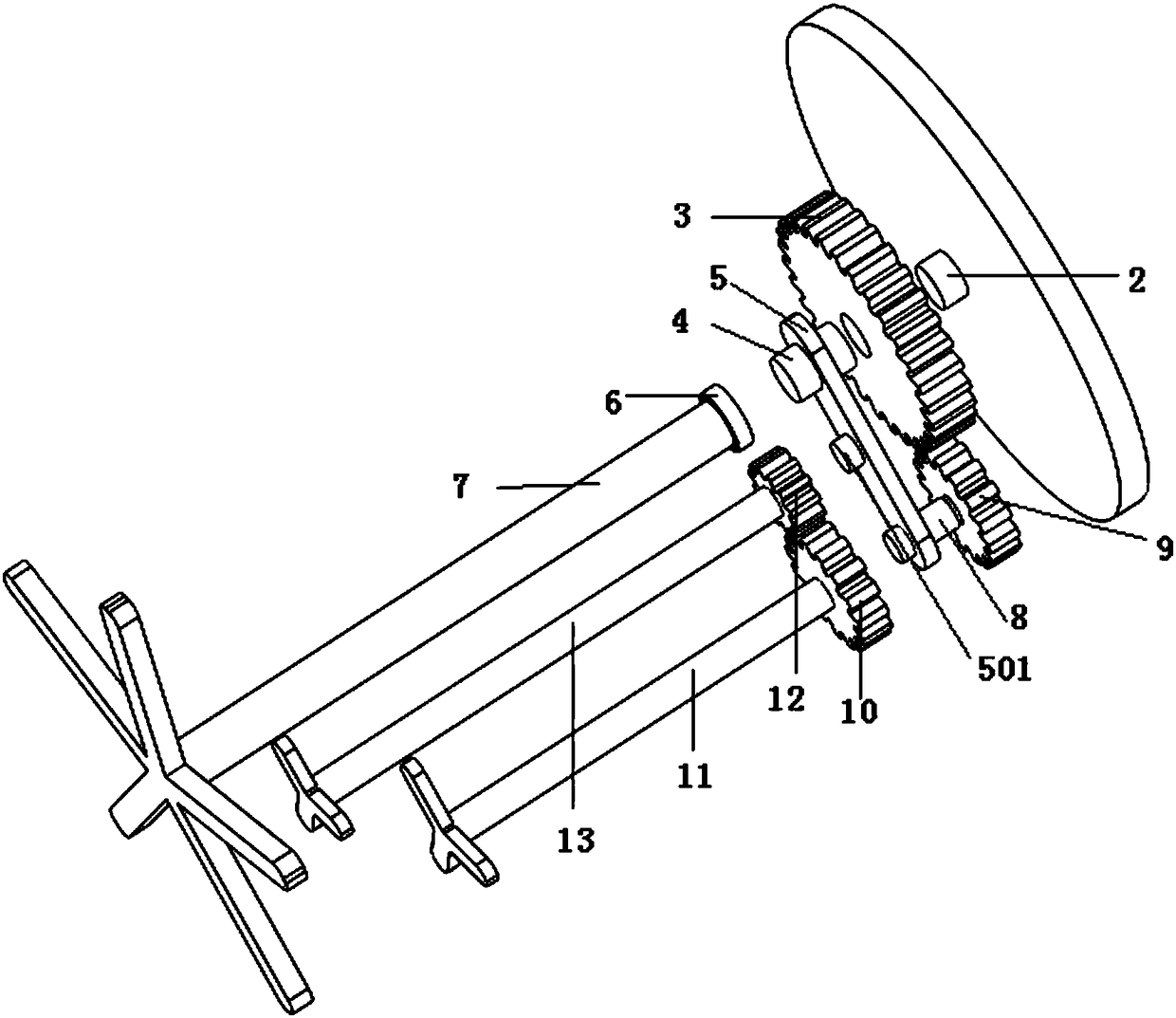

[0071] A special concrete preparation device for roads and bridges, including high-efficiency mixing containers, such as figure 1 , figure 2 with image 3 As shown, the high-efficiency mixing container includes a mixing tank 1, the top center of the mixing tank 1 is provided with an installation through hole, the bottom is provided with a discharge port, and a discharge valve is installed at the discharge port, and the side wall of the mixing tank 1 is installed with an inlet Material channel 101;

[0072] The first rotating shaft 2 is installed and fixed in the installation through hole, and the first gear 3 is installed and fixed on one end of the first rotating shaft 2, and the other end is connected with the power output end of the reduction motor, and the bottom end surface of the first gear 3 is fixed with the first gear 3. Two rotating shafts 4, the middle part of the second rotating shaft 4 is sleeved with a horizontally distributed positioning plate 5, the bottom e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com