Environment-friendly micro-electrolysis ceramsite and preparation method thereof

An environmentally friendly, micro-electrolysis technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. Frequent replacement of electrolytic fillers, etc., to achieve the effect of being conducive to resource utilization, not easy to harden, and improve biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

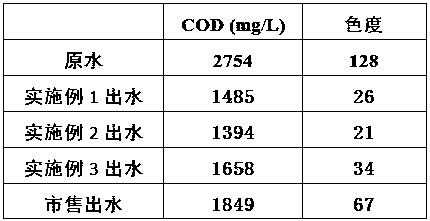

Examples

Embodiment 1

[0025] An environment-friendly micro-electrolytic ceramsite, which is made of the following raw materials according to mass percentage: 30 g of nano-zero-valent iron, 25 g of activated carbon, 25 g of river and lake sludge, 5 g of dispersant, 5 g of binder, and pore-forming agent 5 g, catalyst 4.8 g and graphene 0.2 g.

[0026] The preparation method of above-mentioned environment-friendly type micro-electrolytic ceramsite, it comprises the steps:

[0027] (1) Stir and mix nano zero-valent iron, activated carbon, river and lake sludge, dispersant, binder, pore-forming agent, catalyst and graphene evenly;

[0028] (2) Put the mixed raw materials in a pulverizer for 30 min, and the particle size of the pulverized material is 150 mesh;

[0029] (3) Add 15 ml of water to the pulverized material to reconcile, and use a granulator to make spherical particles with a particle size of 1 cm;

[0030] (4) The spherical particles were placed in a muffle furnace and dried at 120 °C for 3...

Embodiment 2

[0032] An environment-friendly micro-electrolytic ceramsite, which is made of the following raw materials by mass percentage: 40 g of nano-zero-valent iron, 20 g of activated carbon, 20 g of river and lake sludge, 5 g of dispersant, 5 g of binder, and pore-forming agent 5 g, catalyst 4.8 g and graphene 0.2 g.

[0033] The preparation method of above-mentioned environment-friendly type micro-electrolytic ceramsite, it comprises the steps:

[0034] (1) Stir and mix nano zero-valent iron, activated carbon, river and lake sludge, dispersant, binder, pore-forming agent, catalyst and graphene evenly;

[0035] (2) Put the mixed raw materials in a pulverizer to pulverize for 40 min, and the particle size of pulverized material is 100 mesh;

[0036] (3) Add 20 ml of water to the pulverized material to reconcile, and use a granulator to make spherical particles with a particle size of 0.5 cm;

[0037] (4) The spherical particles were placed in a muffle furnace and dried at 100 °C for ...

Embodiment 3

[0039] An environmentally friendly micro-electrolytic ceramsite, which is made of the following raw materials according to mass percentage: 30 g of nano-zero-valent iron, 20 g of activated carbon, 30 g of river and lake sludge, 6 g of dispersant, 6 g of binder, and pore-forming agent 6 g, catalyst 1.5 g and graphene 0.5 g.

[0040] The preparation method of above-mentioned environment-friendly type micro-electrolytic ceramsite, it comprises the steps:

[0041] (1) Stir and mix nano zero-valent iron, activated carbon, river and lake sludge, dispersant, binder, pore-forming agent, catalyst and graphene evenly;

[0042] (2) Put the mixed raw materials in a pulverizer for 30 min, and the particle size of the pulverized material is 200 mesh;

[0043] (3) Add 20 ml of water to the pulverized material for reconciliation, and use a granulator to make spherical particles with a particle size of 2 cm;

[0044] (4) The spherical particles were placed in a muffle furnace and dried at 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com