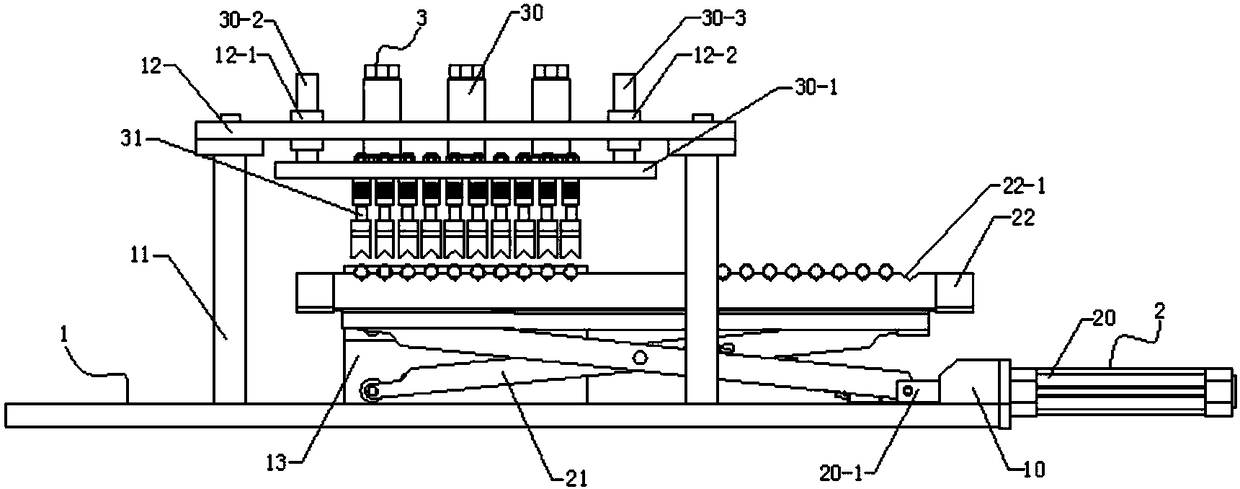

Cylindrical workpiece loading and compressing device

A technology of pressing device and cylindrical workpiece, applied in metal processing and other directions, can solve the problem of low efficiency, and achieve the effects of stable device structure, good pressing effect and guaranteeing machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

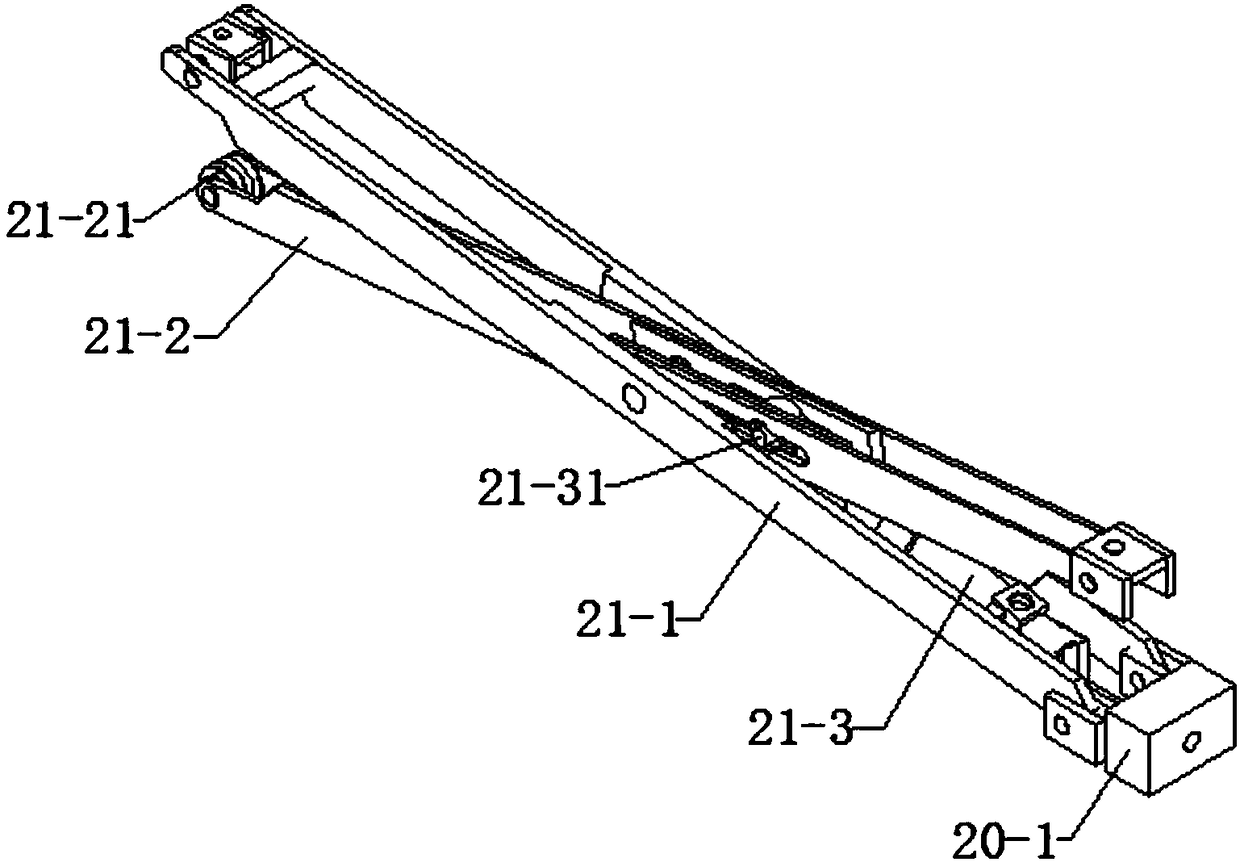

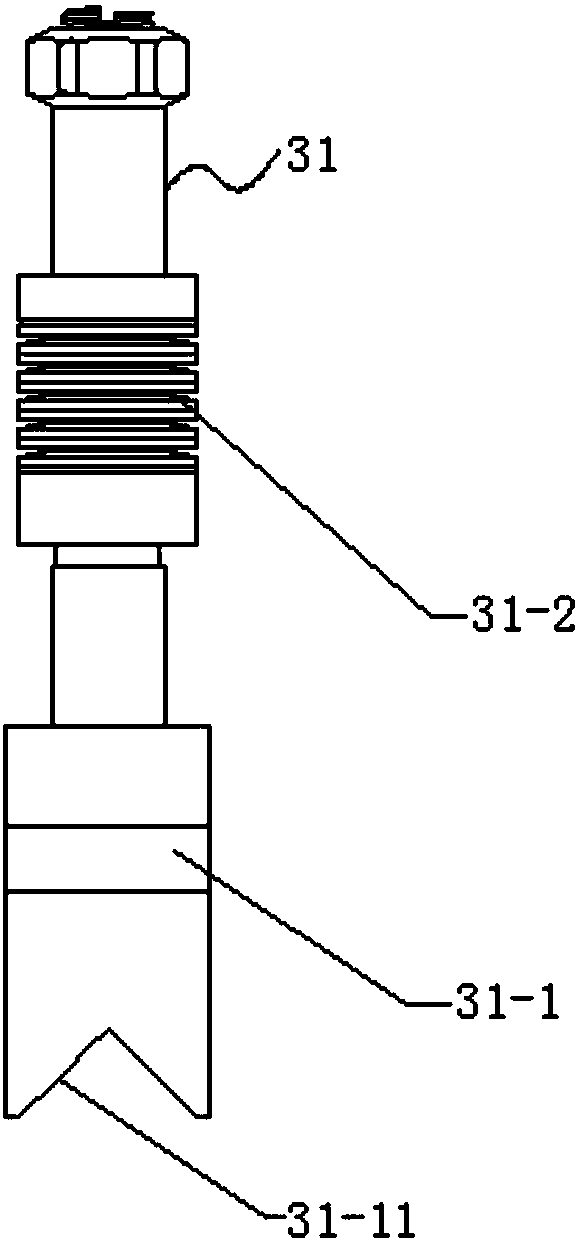

[0025] This invention pushes the connecting rod mechanism 21 forward through the electric push rod 20, and the piston rod of the small cylinder 21-3 is elongated forward to push the connecting rod 2 21-2 hinged at the front end to open, thereby making the connecting rod mechanism 21 rise. Drive the feeding plate 22 to rise, and after the feeding plate 22 is raised to a specific position, the electric push rod 20 and the small cylinder 21-3 are kept stable, and the upper surface of the feeding plate 22 is provided with a V-shaped discharge groove 22-1 , can prevent the cylindrical workpiece from rolling to both sides during the pressing process, and the pulley at the lower end of the connecting rod 21-2 effectively ensures the stability of the connecting rod mechanism 21 in the process of moving forward, and moves the discharge area to the pressing mechanism 3 Directly below, each compression rod 31 correspondingly compresses a cylindrical workpiece placed in the V-shaped discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com