Activated carbon box for waste gas treatment in workshop

A workshop waste gas and activated carbon technology, which is applied to the separation of dispersed particles, chemical instruments and methods, and dispersed particle filtration, can solve the problems of small contact area between activated carbon and waste gas, low waste gas treatment capacity, and reduced adsorption capacity, so as to save manpower, High adsorption efficiency and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

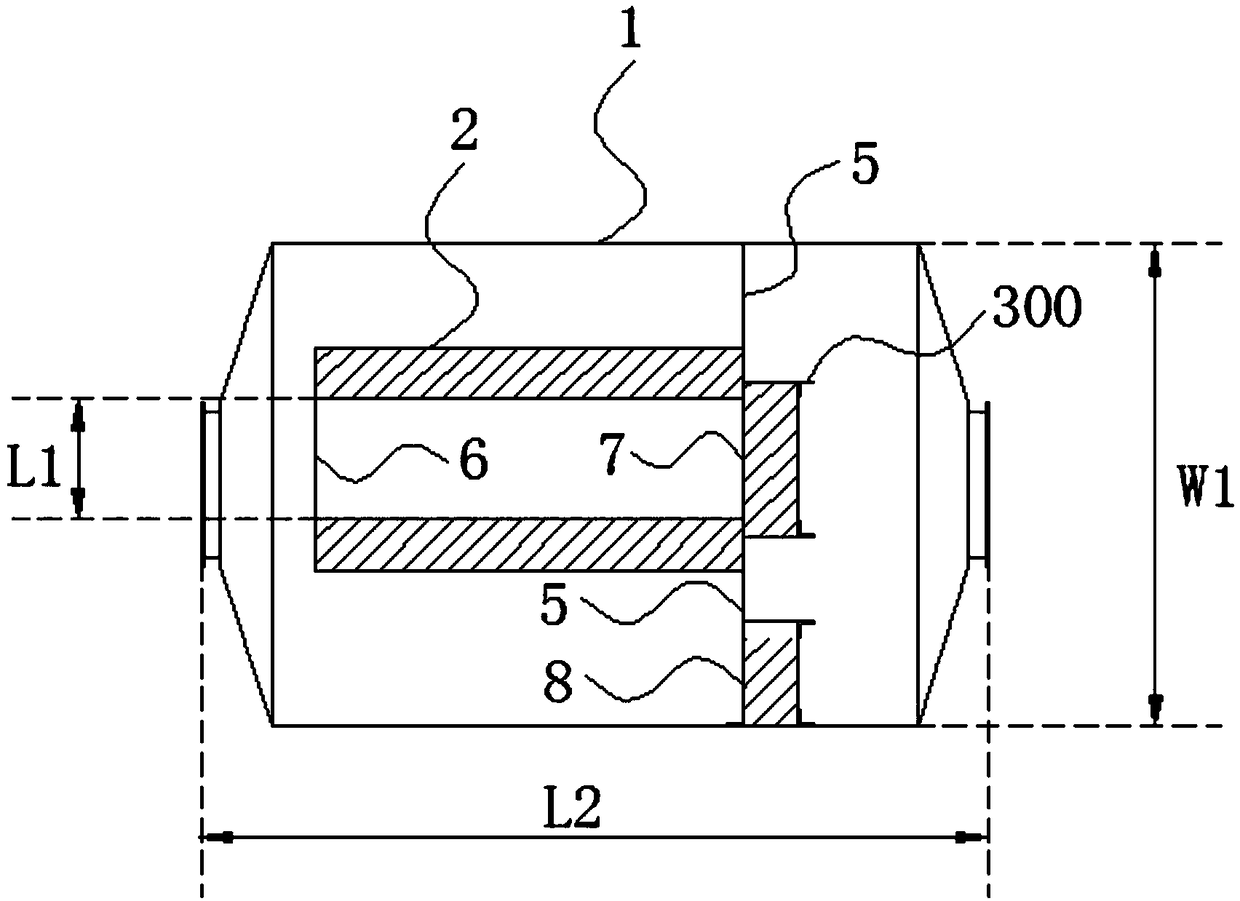

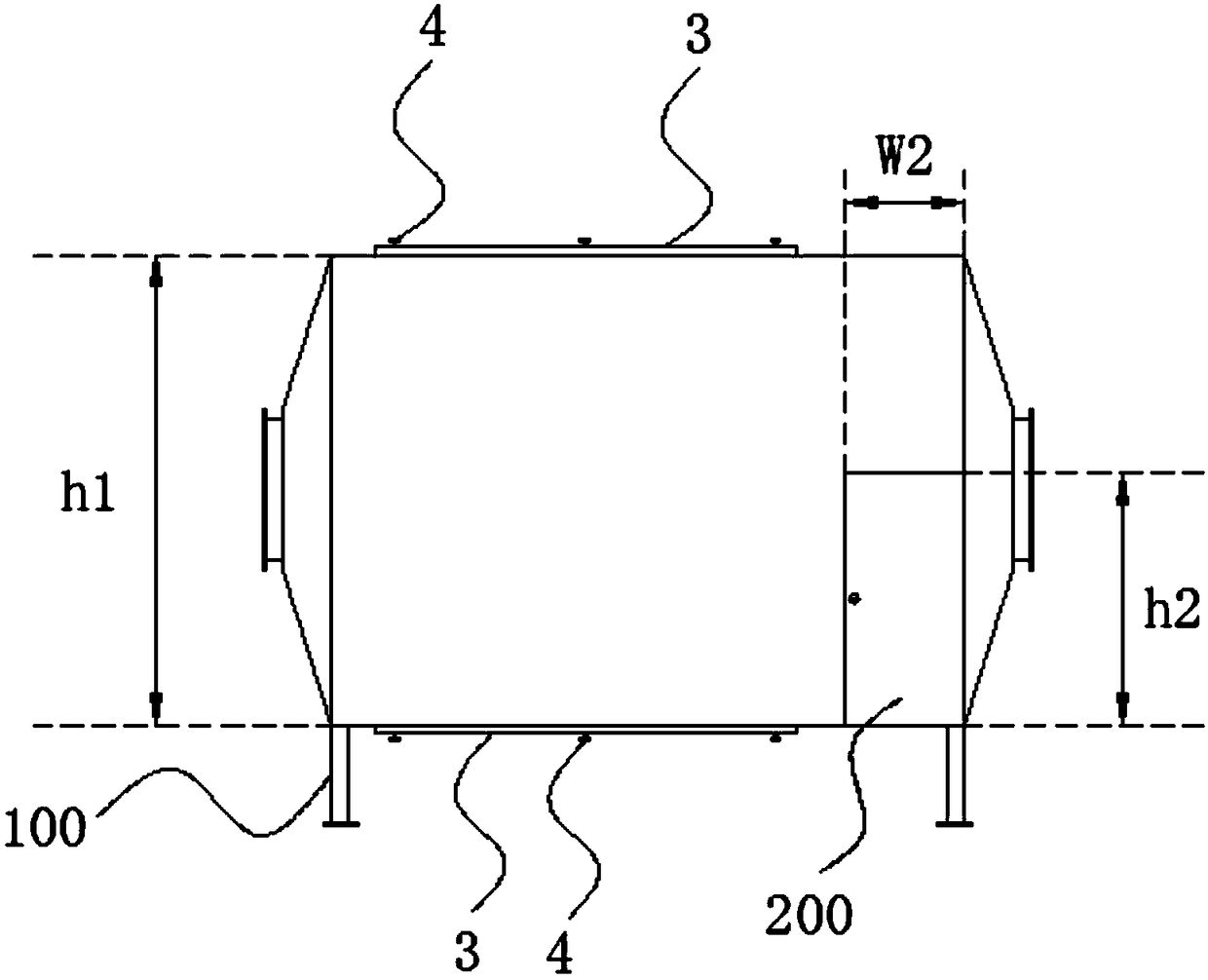

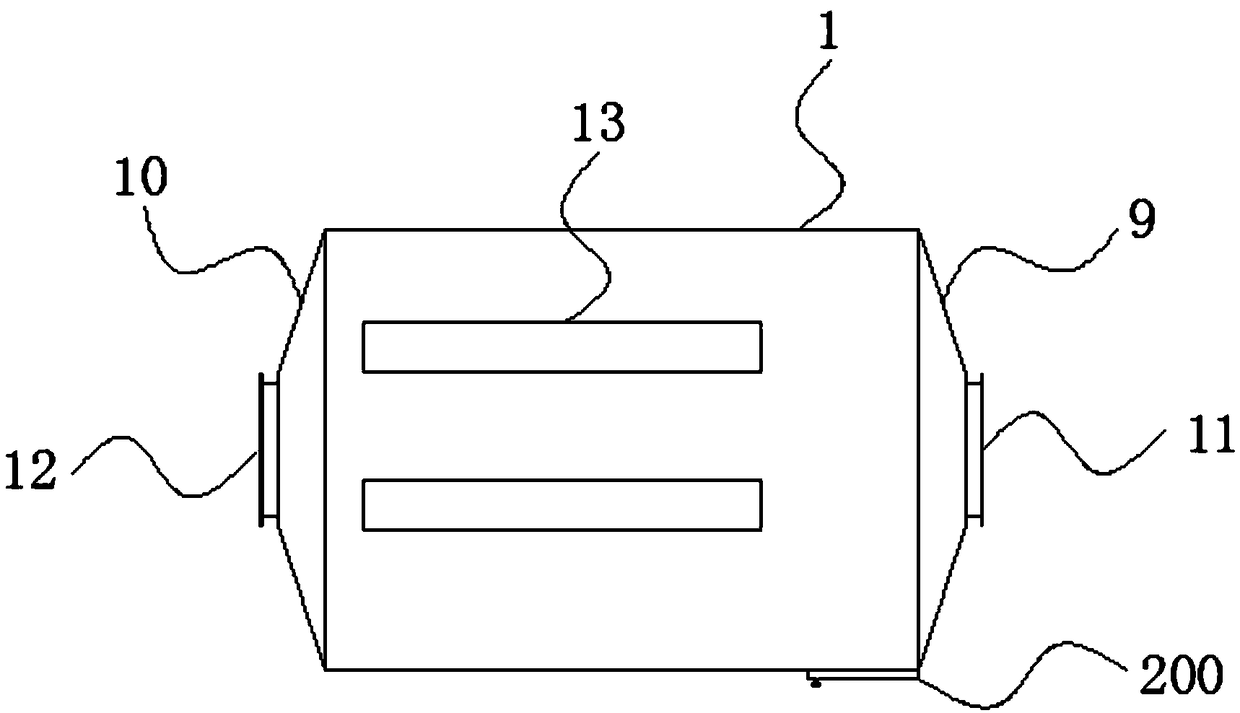

[0034] Embodiment: a kind of activated carbon box for workshop exhaust gas treatment, such as Figure 1-Figure 4 As shown, it includes a box body 1 and two layers of filter layers 2 positioned inside the box body 1, one end of the box body 1 is provided with an air inlet 11, and the other end of the box body 1 is provided with an air outlet 12, Two layers of the filter layer 2 are arranged along the length direction of the box body 1 and are perpendicular to the bottom surface of the box body 1. There is a gas flow channel between the two layers of the filter layer 2. The filter layer 2 includes a The inner air intake surface between the two filter layers 2 and the outer air outlet surface opposite to the inner air intake surface, the air inlet 11 communicates with the inner air intake surface, and the inner air intake surface is connected to the inner air intake surface. The outer air outlet surface communicates, and the outer air outlet surface communicates with the air outl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com