Water taking well and recharge well quick-replaced pipeline system and operation process

A pipeline system and recharge well technology, applied in geothermal energy systems, heat collectors using groundwater as the working fluid, heating fuel, etc., can solve the problems of high cost, cumbersome operation, and poor heating effect, and achieve The effect of removing silt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

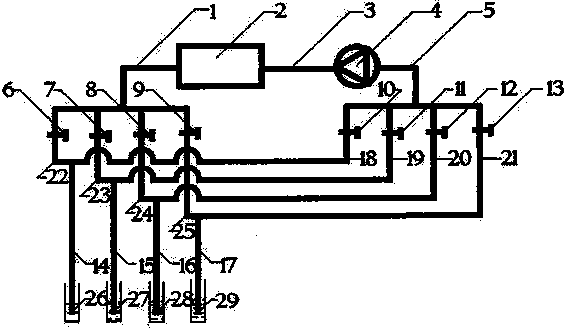

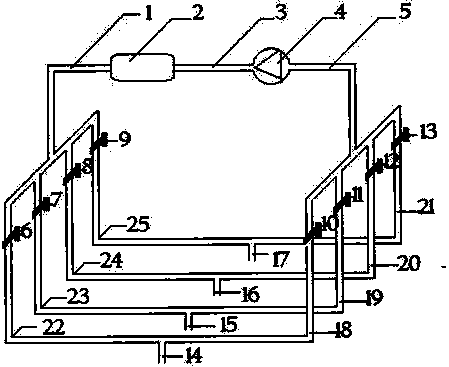

[0029]Embodiment 1: In this embodiment, the water source heat pump system adopts a different well recharge system, and a water intake well and three recharge wells are set up. Both the water intake well and the reinjection well have a depth of 50 meters, a diameter of 600 meters, and a well spacing of 20 to 25 meters. The water intake pipe and the refilling water pipe are all made of steel pipes, and the diameter of the pipe is DN159mm. The water intake is equipped with a water pump (4) and a backup pump, and the design water intake is 85m 3 / h, the design flow rate of a single pump is 95m 3 / h.

[0030] The closing and opening of the electric valve on the pipeline is automatically controlled by a timing device, and the operation time of a single water intake well is set to 2 hours each time. The operation steps are as follows:

[0031] 1. When the system is running, water intake / refilling 1 # Well (26) is used as water intake well, other water intake / recharge 2 # Well (2...

Embodiment 2

[0036] The water-source heat pump system in this embodiment adopts a different-well recharge type water system, and is provided with one water intake well and three recharge wells. The closing and opening of the electric valve on the pipeline is automatically controlled by a quantitative device. After the system has been running for a period of time, if the water level of a certain reinjection well reaches the set height, the system will automatically adjust and replace the water supply well and the return water well. The implementation steps are as follows:

[0037] 1. When the system is running, water intake / refilling 1 # Well (26) is used as water intake well, other water intake / recharge 2 # Well (27), Water Intake / Recharge 3 # Well (28), water intake / recharge 4 # Well (29) operates as a recharge well; now the automatic control system automatically opens the water intake 1 # Pipe valve (10), automatically shuts off water intake 2 # Pipe valve (11), water intake 3 # Pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com