Travelling type hull cracking leakage stop device

A walking device and walking-type technology, which is applied to the safety of ships, transportation and packaging, ships, etc., can solve the problems of inconvenient plugging operation and inconvenient plugging operation of ship crawler-type quick-blocking boards, and achieve convenient operation, The effect of high plugging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

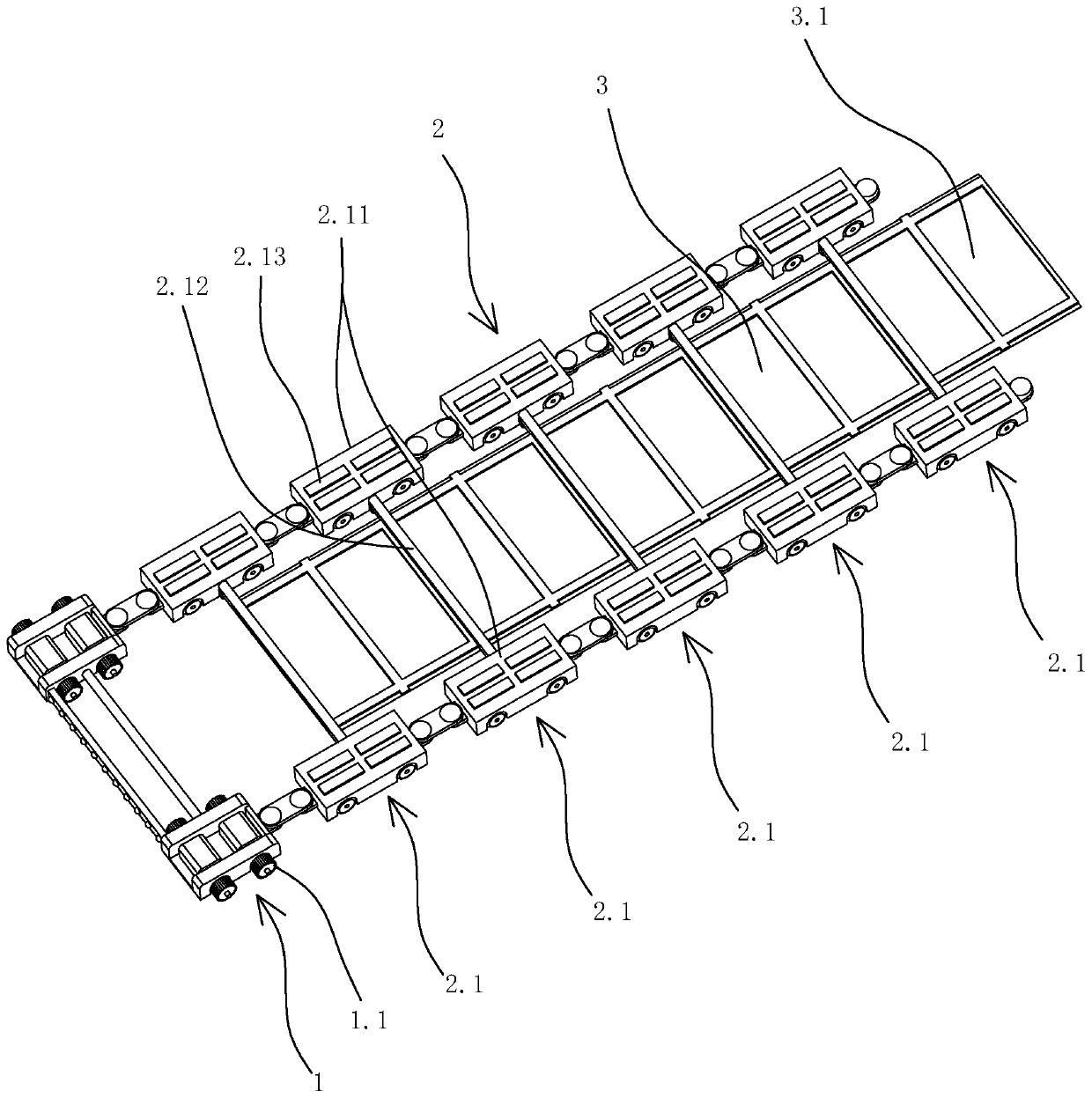

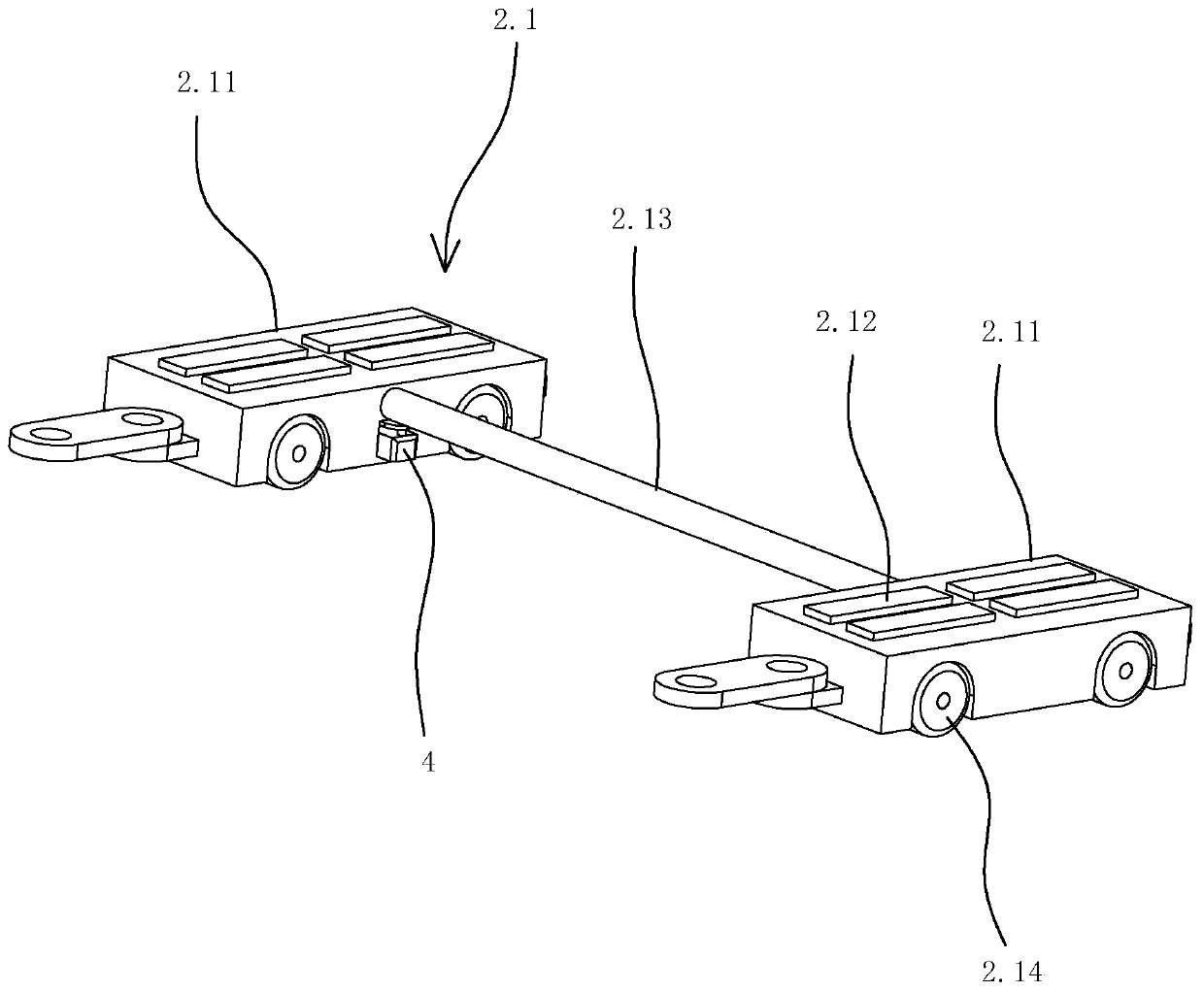

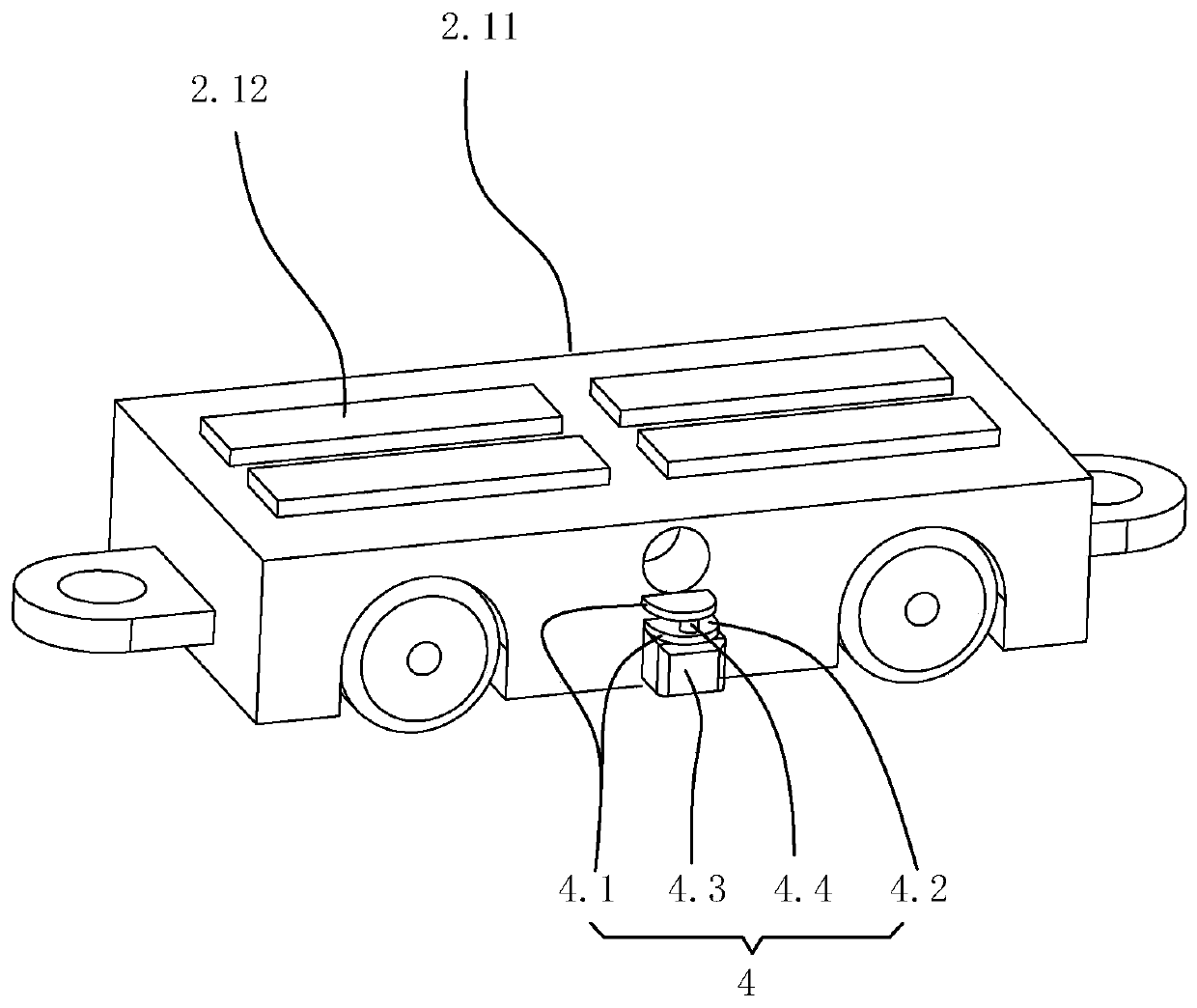

[0032] Specific embodiment one: as figure 1 , figure 2 As shown, a walking type hull crack plugging device includes a walking device and a magnetic sealing belt device 3 . The traveling device comprises a driving car 1, a driven car group 2 connected to the driving car and a sealing tape installation device for installing a magnetic sealing tape device.

[0033] Such as figure 1 As shown, the driving car 1 includes several magnetic wheels 1.1, the driving car is adsorbed on the outer wall surface of the hull through the magnetic wheels, and walks on the outer wall surface of the hull through the magnetic wheels. The motor vehicle also includes a waterproof motor for driving the magnetic wheel to rotate, and the waterproof motor drives the magnetic wheel to rotate so that the driving vehicle can walk on the outer wall surface of the hull. In this embodiment, the magnetic wheel includes a wheel and a plurality of magnets that are evenly distributed on the tread of the wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com