Micro engine combustion chamber evaporation pipe with inlet rotational flow blades

A technology of swirling blades and evaporating tubes, which is applied in the field of evaporating tubes in micro-engine combustion chambers, can solve problems such as poor atomization and evaporation effects of evaporating tubes, difficult engine ignition, and inability to atomize fuel, so as to increase the residence time and improve the residence time. Time, full effect of burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described now in conjunction with accompanying drawing:

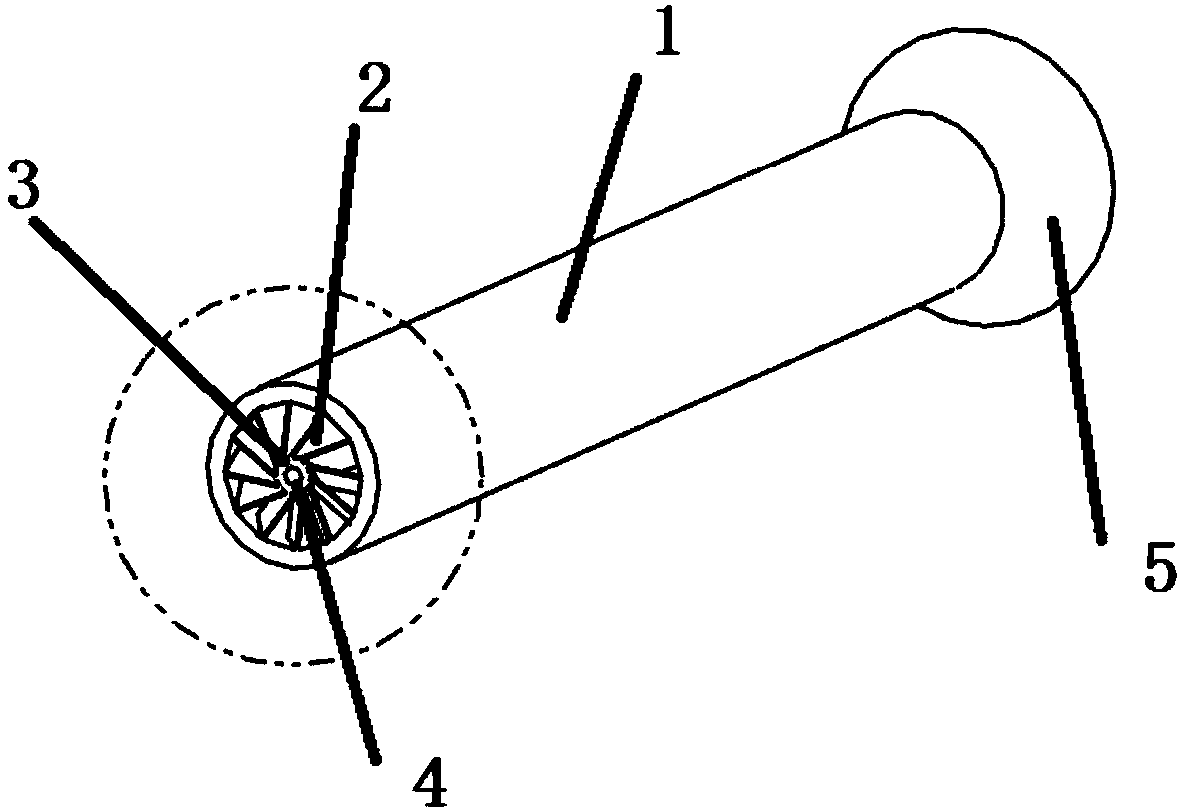

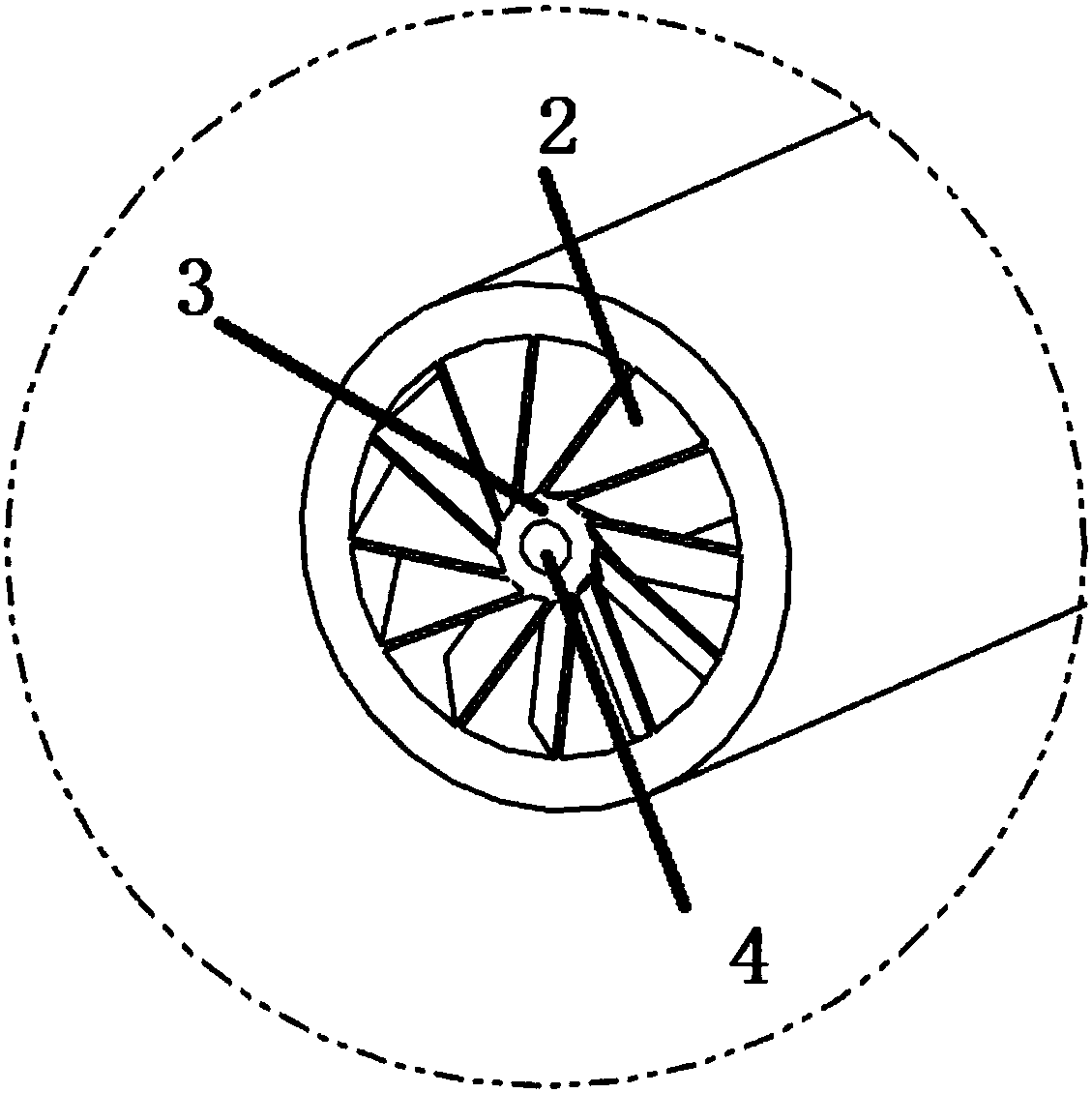

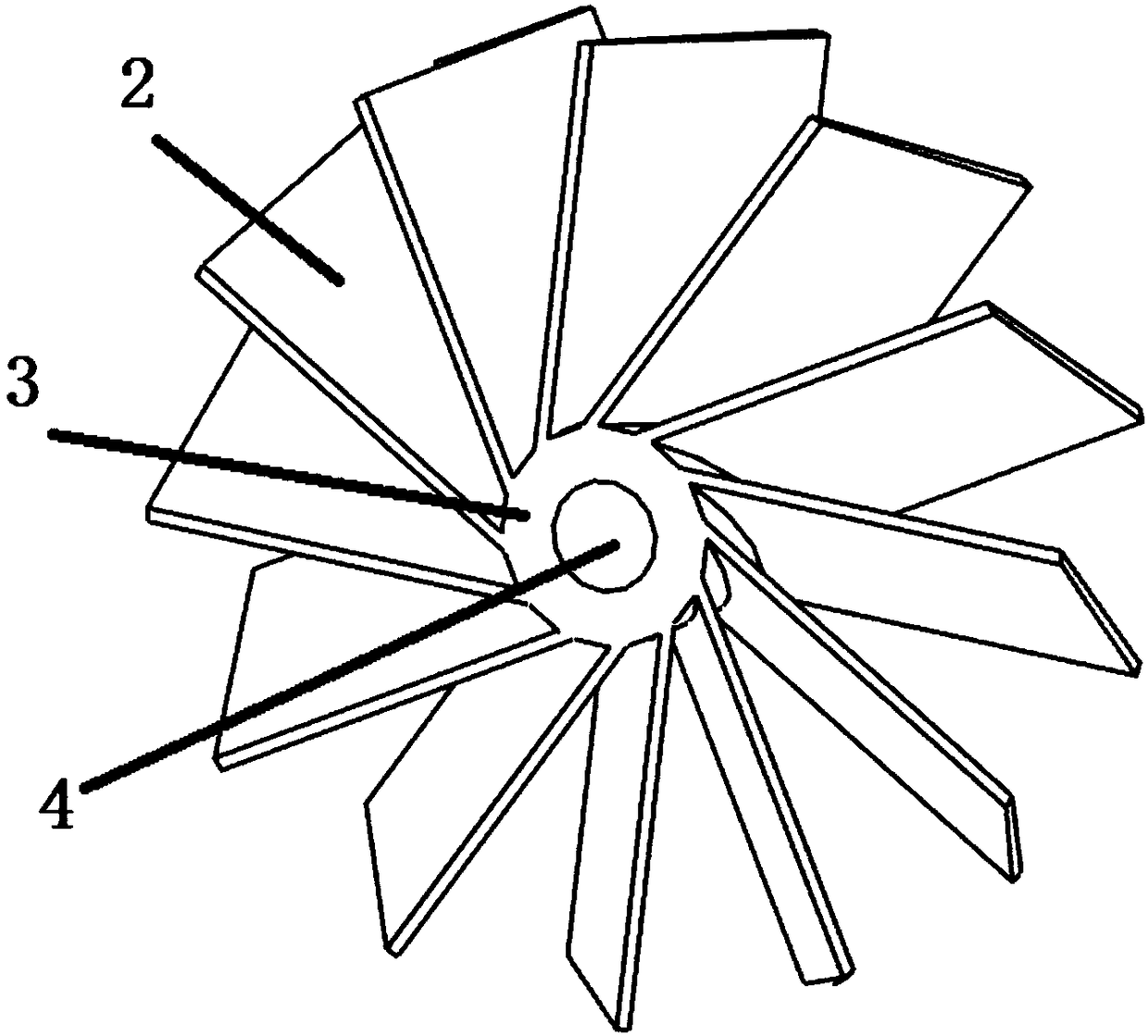

[0022] combine figure 1 , figure 2 , image 3 and Figure 4 , The invention provides a structural design scheme of an evaporating tube of a combustion chamber of a micro-engine with inlet swirl vanes. figure 1 It is an overall schematic diagram of the evaporating tube of a micro-engine combustor with inlet swirl vanes, figure 2 It is a partial enlarged view of the inlet of the evaporator tube, image 3 Schematic diagram of swirl blade structure, Figure 4 It is a schematic diagram of the distribution of swirl blades in each group.

[0023] according to figure 1 As shown, when the external air flows through the inlet swirl blade (2) and enters the evaporator tube (1), it is deflected by the rotation of the inlet swirl blade (2), and the axial velocity decreases to obtain the radial and tangential Velocity, this airflow with three sub-velocities has a great degree of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com