Metal sheet material with texture decorative effect and manufacturing method thereof

A decorative effect and metal sheet technology, applied in the field of decorative materials, can solve single problems and achieve the effect of simple production process, easy operation of production process and rich texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a metal sheet with a textured decorative effect, comprising the following steps:

[0029] (1) Coating or pouring the slurry into a textured silicone mold to form a surface decoration layer, the thickness of the coating or pouring is 1-3mm;

[0030] (2) heating the surface decoration layer to 50-150°C until the surface decoration layer is in a semi-cured state;

[0031] (3) Apply a slurry layer with a thickness of 0.2 to 1 mm on the non-textured back of the semi-cured surface decoration layer, and press a metal sheet (frame) with holes on the slurry layer until it is cured and formed.

[0032] The holes on the sheet metal (frame) are circular or square.

[0033] The metal sheet is an iron sheet or an iron alloy sheet. The thickness of the iron sheet or iron alloy sheet is preferably 0.2-1 mm. The iron alloy sheet is preferably a color steel plate.

[0034] The metal frame is an aluminum frame. The aluminum frame is filled with insulation mater...

Embodiment 2

[0040] A metal sheet with a textured decorative effect prepared by the method described in Example 1.

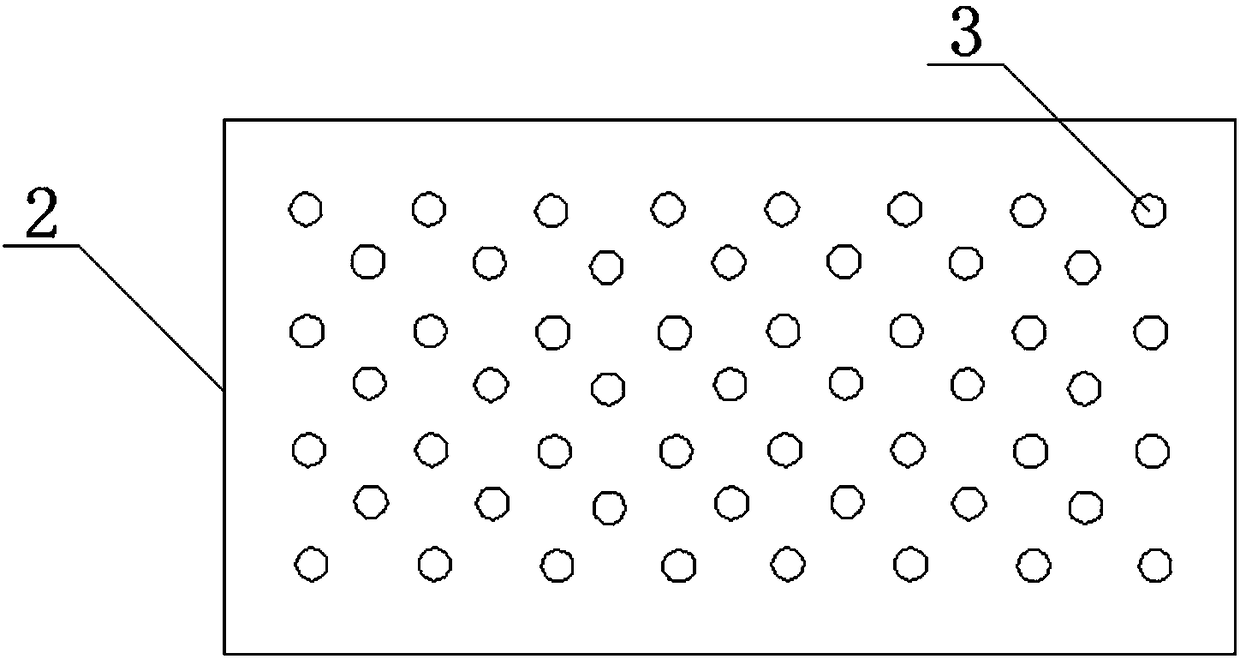

[0041] Such as figure 1 and 2 As shown, the metal sheet includes a surface decoration layer 1 and a metal sheet 2, and the surface decoration layer 1 and the metal sheet 2 are solidified together by slurry. The metal sheet 2 is provided with a hole 3, and the hole 3 of the metal sheet 2 can play the role of an anchor after the grout is solidified, so that the surface decoration layer 1 and the metal sheet 2 are firmly connected, and also has the function of ventilation.

Embodiment 3

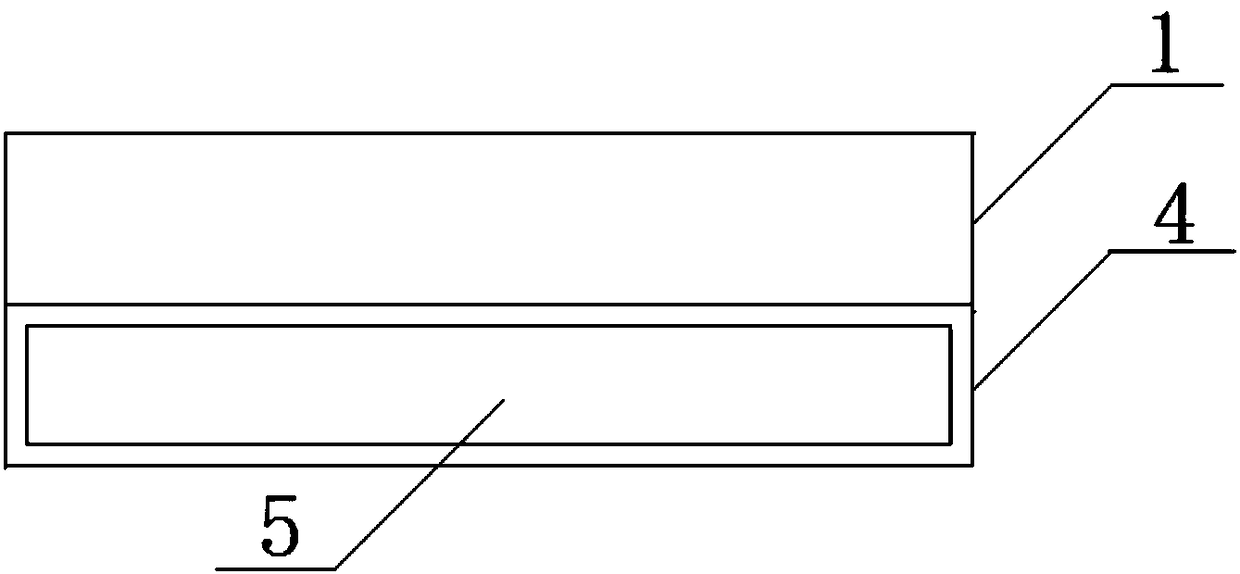

[0043] A metal sheet with a textured decorative effect prepared by the method described in Example 1.

[0044] Such as image 3 As shown, the metal sheet includes a surface decoration layer 1 and a metal frame 4, and the surface decoration layer 1 and the metal frame 4 are solidified together by slurry. The metal frame 4 is an aluminum frame. The aluminum frame 4 is filled with thermal insulation material 5 . The insulation material is EPS, XPS or polyurethane. The metal frame 4 is provided with holes (the holes are at least arranged on the side where the metal frame 4 is in contact with the surface decoration layer 1), and the holes of the metal frame 4 can serve as anchors after the grout is solidified, so that the surface decoration layer 1 It is firmly connected with the metal sheet 2 and also has a breathable effect.

[0045] In the invention, the metal sheet (frame) is compounded on the back of the surface decoration layer, and the metal sheet (frame) with holes is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com