High temperature resistance anion exchange resin preparation method

An exchange resin and anion technology, applied in anion exchange, ion exchange, chemical instruments and methods, etc., can solve the problems of high cost and complex synthesis route, achieve excellent temperature resistance, huge application value, and reduce air cooling heat loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

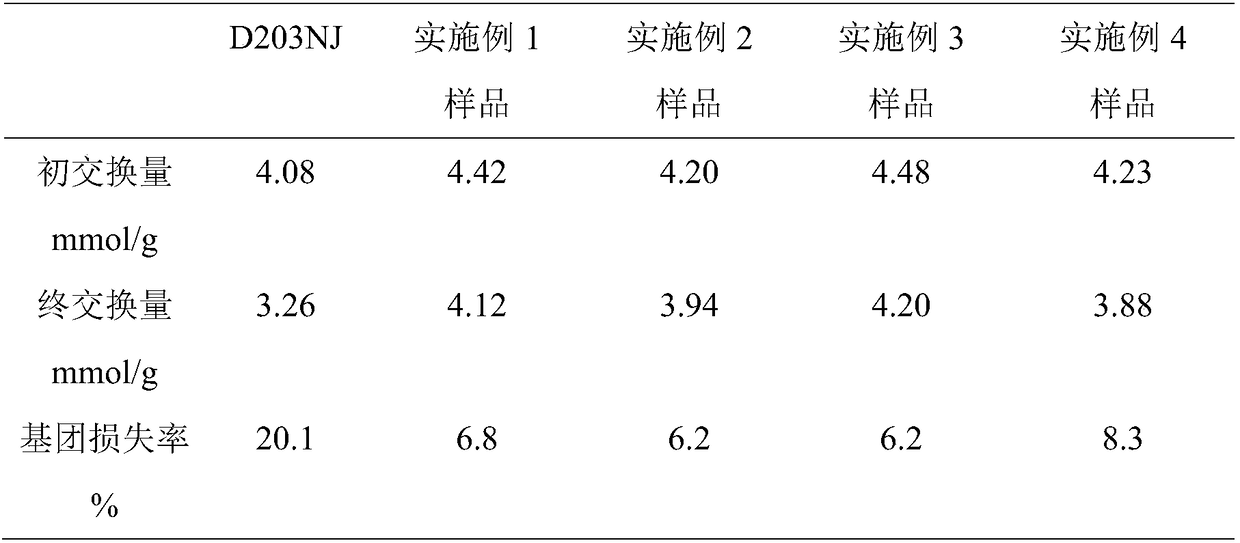

Examples

preparation example Construction

[0024] A kind of preparation method of high temperature resistant anion exchange resin of the embodiment of the present invention comprises:

[0025] Step 10) Mix the hydroxyethyl cellulose, sodium chloride and deionized water, heat and stir until clear and transparent to obtain an aqueous phase reaction solution.

[0026] Wherein, in step 10), preferably, the mass ratio of hydroxyethyl cellulose, sodium chloride and deionized water is 1:(2-10):(480-500). Preferably, it is heated to a temperature of 60-65°C. In this temperature range, hydroxyethyl cellulose dissolves.

[0027] Step 20) Mix the initiator, porogen and polymerized monomer, and stir to obtain an oil phase reaction liquid.

[0028] Wherein, in step 20), preferably, the mass ratio of the initiator, the porogen and the polymerizable monomer is 1:(120-160):(150-500). Preferably, the initiator is one or any combination of benzoyl peroxide, ammonium persulfate, and azobisisobutyronitrile. The porogen is one or any c...

Embodiment 1

[0044] Mix 2 g of hydroxyethyl cellulose, 10 g of sodium chloride and 1000 g of deionized water, heat to 65° C., and stir until clear and transparent to obtain an aqueous phase reaction liquid. 1 g of benzoyl peroxide, 120 g of n-hexane, 205 g of styrene and 3 g of divinylbenzene were mixed and then stirred to obtain an oil phase reaction liquid. The oil phase reaction liquid and the water phase reaction liquid are mixed, and the mass ratio of the oil phase reaction liquid and the water phase reaction liquid is 1:2.3. Stir and heat up to 70°C for 2 hours, stop heating, add 8 g of divinylbenzene after cooling to 50°C, stir for 10 hours, heat up to 70°C for 2 hours, then heat up to 80°C for 3 hours, and finally heat up to 90°C for 6 hours, toluene Extract to remove the porogen, dry and sieve to obtain resin white balls. Mix resin white balls with chloromethyl ether, and the volume ratio of resin white balls to chloromethyl ether is 1:4, then add 2.02g SbCl 5 As a catalyst, sti...

Embodiment 2

[0046] Mix 1 g of hydroxyethyl cellulose, 10 g of sodium chloride and 480 g of deionized water, heat to 60° C., and stir until clear and transparent to obtain a water phase reaction liquid. 0.5 g of azobisisobutyronitrile, 80 g of liquid paraffin oil, 247.5 g of styrene and 2.5 g of divinylbenzene were mixed and stirred to obtain an oil phase reaction liquid. The oil phase reaction liquid and the water phase reaction liquid are mixed, and the mass ratio of the oil phase reaction liquid and the water phase reaction liquid is 1:2.4. Stir and heat up to 75°C for 1 hour, stop heating, add 7.5 g of divinylbenzene after cooling to 55°C, stir for 12 hours, heat up to 75°C for 1 hour, then heat up to 85°C for 4 hours, and finally heat up to 95°C for 5 hours. Extract with toluene to remove the porogen, dry and sieve to obtain resin white balls. Mix resin white balls with chloromethyl ether, and the volume ratio of resin white balls to chloromethyl ether is 1:5, then add 2.5g SbCl 5 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com