Explosive material nanowire and preparation method thereof

A technology of nanowires and explosives, which is applied to explosives processing equipment, single substance used as explosives, explosives, etc., can solve the problems such as the preparation method of nanowires without explosives, and achieve uniform morphology, mild reaction conditions and unique nanowire structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

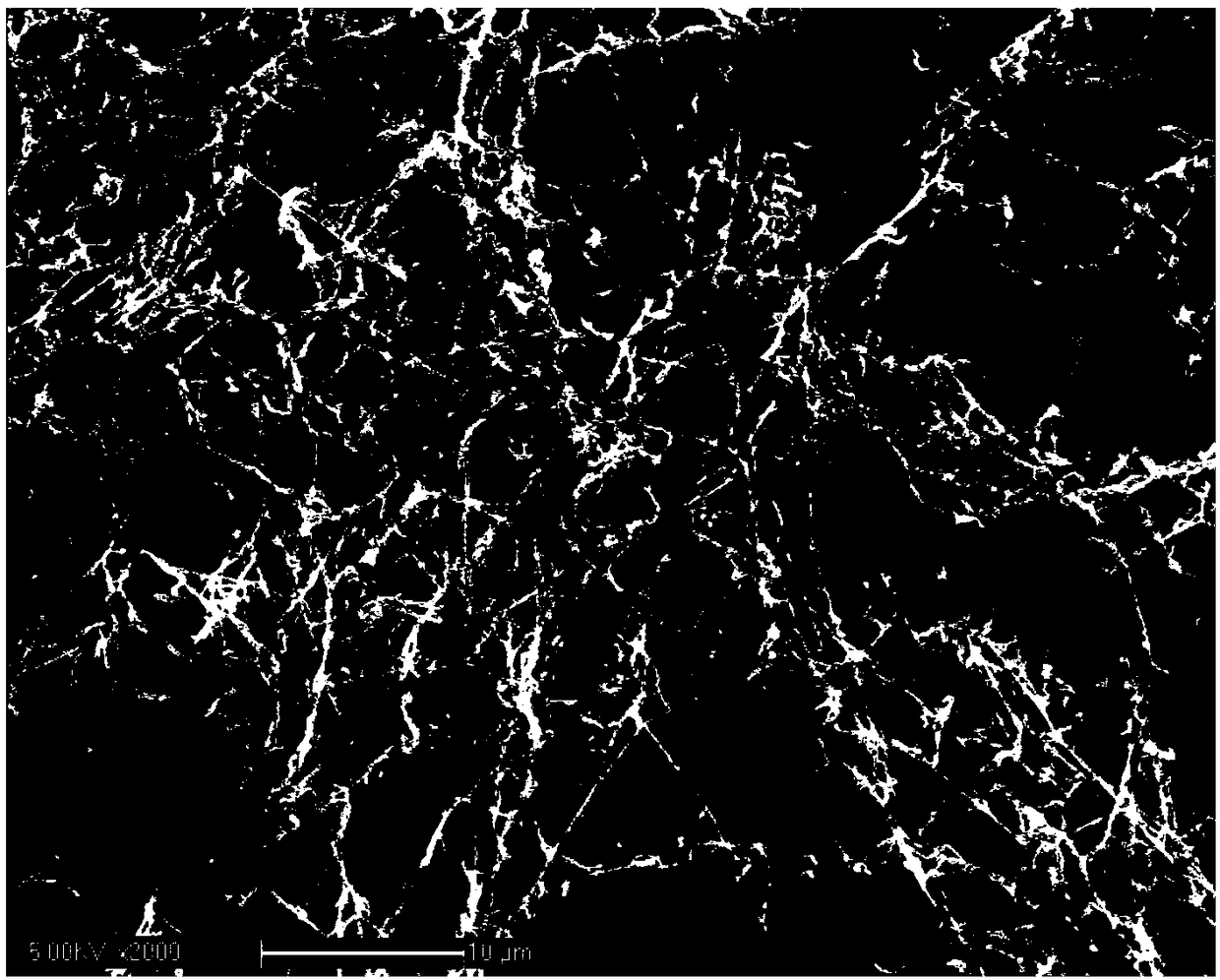

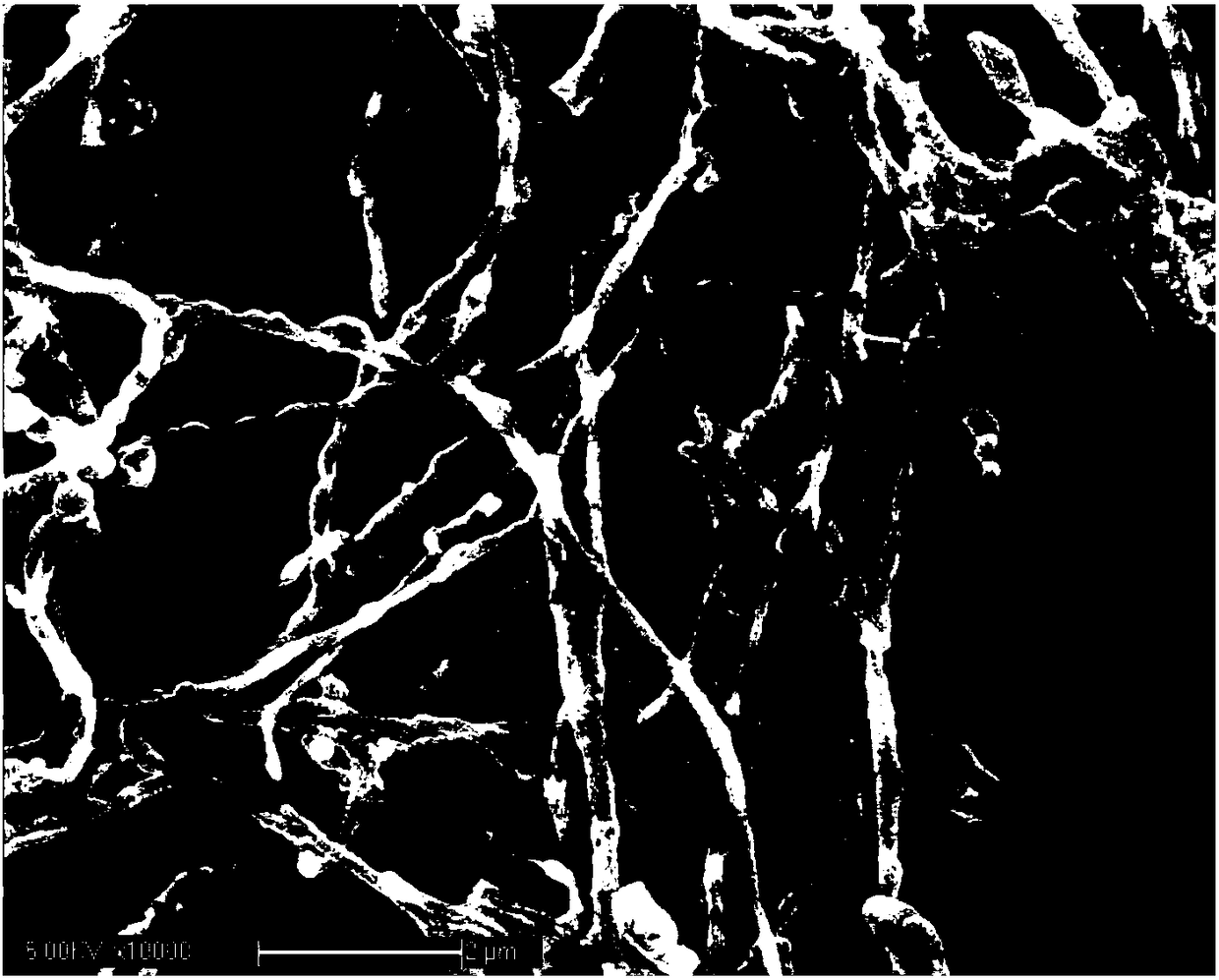

[0022] Weigh 0.5g of 1,1'-dihydroxy-5,5'-bitetrazolium dihydroxylamine salt, add 100g of water, heat to 75°C until the explosive is completely dissolved, and prepare an explosive solution with a concentration of 0.5% by mass . The solution was transferred to a polytetrafluoroethylene bottle, and quenched with liquid nitrogen for 5 minutes until the solution was completely frozen into a solid state. The freeze-solidified solution is freeze-dried under vacuum conditions, the freeze-drying temperature is -80° C., the vacuum degree is 1.5 mba, and the treatment time is 48 hours, and the explosive with the nanowire structure can be obtained. figure 1 and figure 2 2000 times and 10000 times scanning electron micrographs of the nano-array ammonium perchlorate obtained according to this embodiment, respectively. The diameter of the obtained explosive nanowire is about 150 nm, and the length of the nanowire is about 50 μm.

Embodiment 2

[0024] Weigh 0.1g of 1,1'-dihydroxy-5,5'-bitetrazole dihydroxylamine salt, add 100g of water, heat to 60°C until completely dissolved, and prepare an explosive solution with a concentration of 0.1% by mass. The solution was transferred to a polytetrafluoroethylene bottle, and quenched with liquid nitrogen for 7 minutes until the solution was completely frozen into a solid state. The freeze-solidified solution is freeze-dried under vacuum conditions, the freeze-drying temperature is -65°C, the vacuum degree is 0.8mba, and the treatment time is 60h, and the explosive with the nanowire structure can be obtained. The diameter of the obtained explosive nanowire is 100 nm, and the length of the nanowire is 20 μm.

Embodiment 3

[0026] Weigh 3.0g of 1,1'-dihydroxy-5,5'-bitetrazole dihydroxylamine salt, add 197g of water, heat to 90°C until completely dissolved, and prepare an explosive solution with a concentration of 1.5% by mass. The solution was transferred to a polytetrafluoroethylene bottle, and quenched with liquid nitrogen for 10 min until the solution was completely frozen into a solid state. The freeze-solidified solution is freeze-dried under vacuum conditions, the freeze-drying temperature is -60° C., the vacuum degree is 0.12 mba, and the treatment time is 24 hours, and the explosive with the nanowire structure can be obtained. The diameter of the obtained explosive nanowire is 250 nm, and the length of the nanowire is 90 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com