Biomass-charcoal basal fertilizer and preparation method therefor

A biochar and base fertilizer technology, applied in the direction of calcium fertilizer, nitrogen fertilizer, potash fertilizer, etc., can solve the problems of easily damaged nutrients and biochar, poor adsorption, insufficient hardness, etc., achieve good bonding effect, good effect, The effect of short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

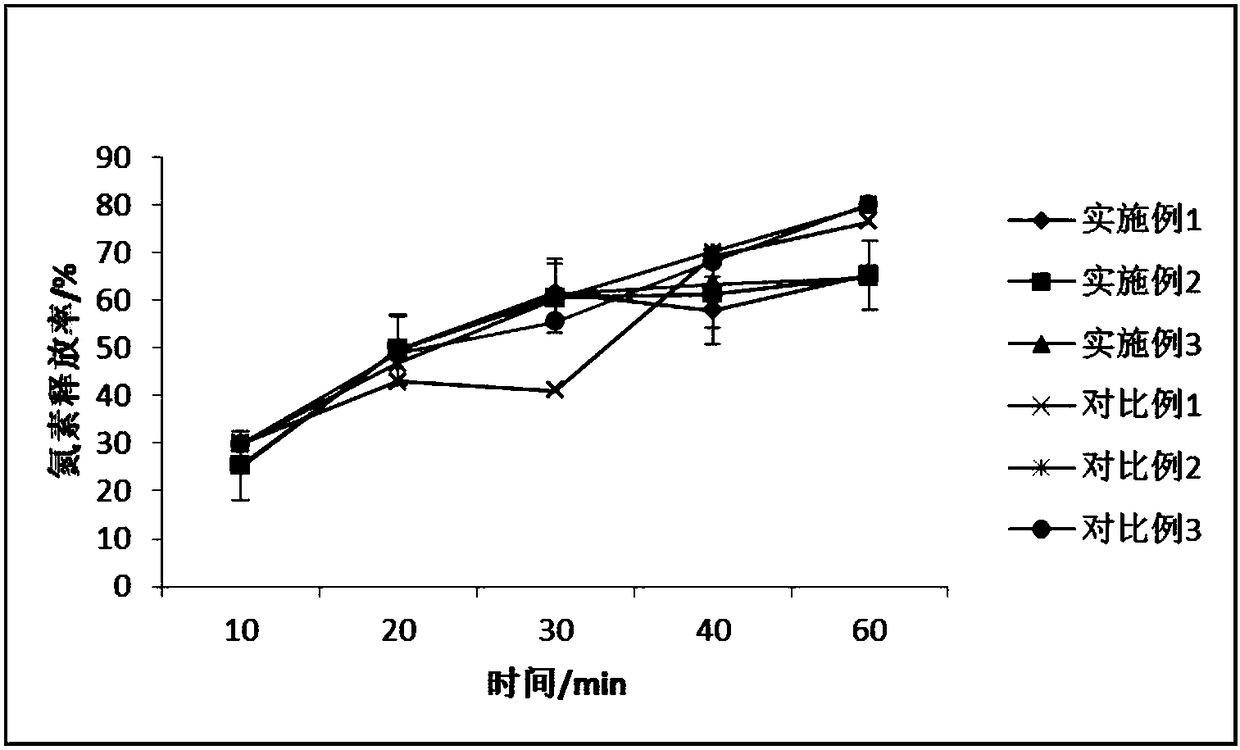

Examples

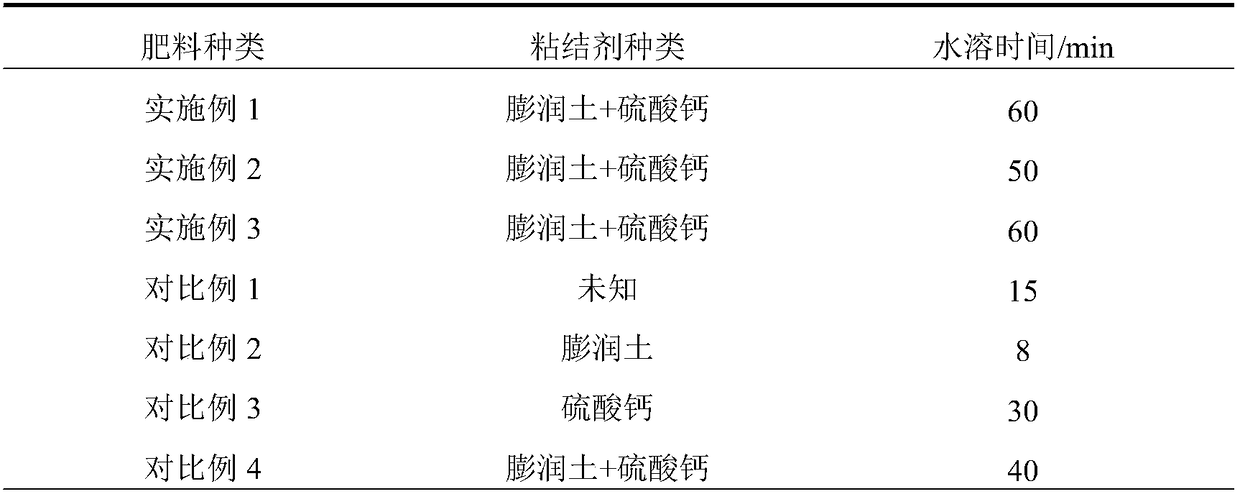

Embodiment 1

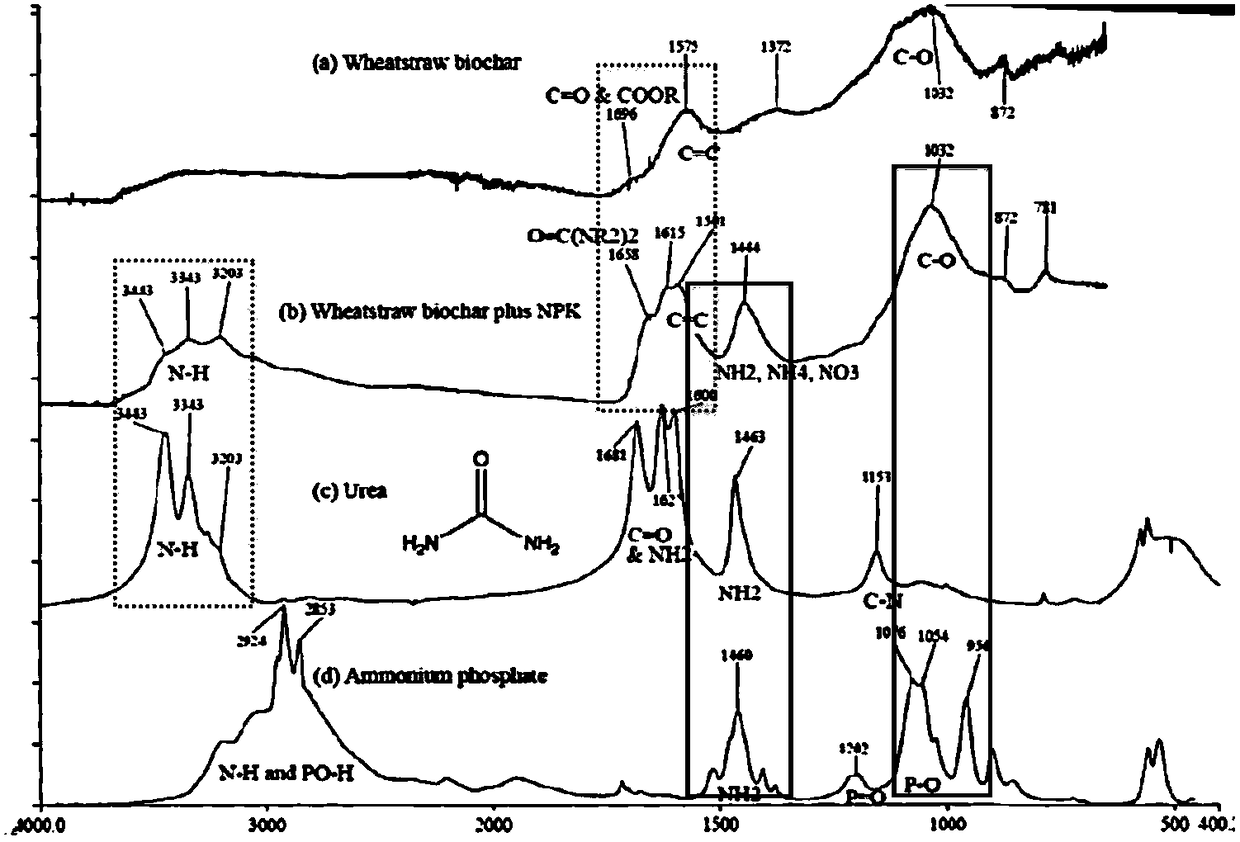

[0026] A biomass charcoal-based fertilizer, comprising the following raw materials in parts by weight: 15kg of biomass charcoal, 30kg of urea, 20kg of ammonium dihydrogen phosphate, 25kg of potassium sulfate, 5kg of bentonite, and 5kg of calcium sulfate.

[0027] Its preparation method is:

[0028] (1) Each component is weighed and mixed uniformly;

[0029] (2) Granulating the mixed raw materials. The granulation process uses high-temperature water vapor as the reaction medium, and the granulation temperature is controlled to be about 100° C. by high-temperature water vapor;

[0030] (3) The formed biochar-based fertilizer granules are rapidly dried at 400° C. to make the moisture content lower than 5%, and then passed through a 20-mesh sieve to obtain biochar-based fertilizers with a fertilizer particle size greater than 1 mm and less than 4.75 mm.

Embodiment 2

[0032] A biomass charcoal-based fertilizer, comprising the following raw materials in parts by weight: 20kg of biomass charcoal, 20kg of urea, 30kg of ammonium dihydrogen phosphate, 15kg of potassium chloride, 10kg of bentonite, and 1kg of calcium sulfate.

[0033] Its preparation method is:

[0034] (1) Each component is weighed and mixed uniformly;

[0035] (2) Granulating the mixed raw materials. The granulation process uses high-temperature steam as the reaction medium, and the granulation temperature is controlled by high-temperature steam to be about 140° C.;

[0036] (3) Rapidly dry the formed biochar-based fertilizer particles at 300° C. to make the moisture content lower than 12%, and then pass through a 20-mesh sieve to obtain biochar-based fertilizers with a fertilizer particle size greater than 1 mm and less than 4.75 mm.

Embodiment 3

[0038] A biomass charcoal-based fertilizer, comprising the following raw materials in parts by weight: 18kg of biomass charcoal, 25kg of urea, 25kg of ammonium dihydrogen phosphate, 20kg of potassium sulfate, 8kg of bentonite, and 3kg of calcium sulfate.

[0039] Its preparation method is:

[0040] (1) Each component is weighed and mixed uniformly;

[0041] (2) Granulating the mixed raw materials. The granulation process uses high-temperature steam as the reaction medium, and the granulation temperature is controlled to be about 120° C. by high-temperature steam;

[0042] (3) Rapidly dry the formed biochar-based fertilizer particles at 350° C. to make the moisture content lower than 5%, and then pass through a 20-mesh sieve to obtain biochar-based fertilizers with a fertilizer particle size greater than 1 mm and less than 4.75 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com