Red mud-steel slag composite geopolymer cementing material for soft base solidification

A technology of soft foundation reinforcement and cementitious materials, applied in the direction of cement production, etc., can solve problems such as adverse environmental impact, unsuitable for large-scale promotion and application, and inconvenient construction, so as to reduce the burden of energy consumption and carbon emissions, and achieve significant economic benefits. Benefits and environmental benefits, the effect of reducing the cost of foundation reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

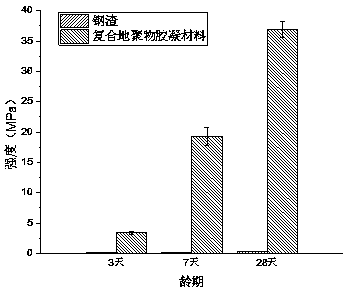

Image

Examples

Embodiment 1

[0027] This example introduces a composite geopolymer cementitious material produced by using red mud and steel slag. The steel slag from a steel factory in Jiaxing City, Zhejiang Province is selected, and its main chemical composition is 48.8% CaO, 27.9% SiO 2 , 8.3%Fe 2 o 3 , 2.3%Al 2 o 3 , loss on ignition 1.6%, the red mud of an aluminum company in Guangxi, its main chemical composition is 20.8% CaO, 14.3% SiO 2 , 8.3%Fe 2 o 3 , 26.5%Al 2 o 3 , loss on ignition 16.9%. The preparation method includes the following steps:

[0028] (1) Naturally air-dry the red mud and steel slag, pass through a 0.5mm sieve after being ground, and bag them separately for later use;

[0029] (2) Prepare composite early-strength superplasticizer for use;

[0030] (3) Weigh red mud, steel slag, cement, metakaolin, and composite water-reducing early-strength agent, with a mass ratio of 50:35:4.5:8.5:2, and first mix the red mud, steel slag, cement, and metakaolin with an industrial mixe...

Embodiment 2

[0034] This example introduces a composite geopolymer cementitious material produced by using red mud and steel slag. The steel slag from a steel factory in Ma'anshan City, Anhui Province is selected, and its main chemical composition is 53.2% CaO, 29.5% SiO 2 , 5.3%Fe 2 o 3 , 3.1%Al 2 o 3 , loss on ignition 2.1%, red mud from an aluminum company in Zibo City, Shandong Province, its main chemical composition is 23.4% CaO, 19.8% SiO 2 , 15.5%Fe 2 o 3 , 21.5%Al 2 o 3 , loss on ignition 12.3%; including the following steps:

[0035] (1) Naturally air-dry the red mud and steel slag, pass through a 0.5mm sieve after being ground, and bag them separately for later use;

[0036] (2) Prepare composite early-strength superplasticizer for use;

[0037](3) Weigh red mud, steel slag, cement, metakaolin, and composite water-reducing early-strength agent at a mass ratio of 42:39:8:10:1, and first mix the red mud, steel slag, cement, and metakaolin with an industrial mixer After un...

Embodiment 3

[0041] This example introduces a composite geopolymer cementitious material produced by using red mud and steel slag. The steel slag from a steel factory in Ma'anshan City, Anhui Province is selected, and its main chemical composition is 53.2% CaO, 29.5% SiO 2 , 5.3%Fe 2 o 3 , 3.1%Al 2 o 3 , loss on ignition 2.1%, the red mud of an aluminum company in Guangxi, its main chemical composition is 20.8% CaO, 14.3% SiO 2 , 8.3%Fe 2 o 3 , 26.5%Al 2 o 3 , loss on ignition 16.9%. Include the following steps:

[0042] (1) Naturally air-dry the red mud and steel slag, pass through a 0.5mm sieve after being ground, and bag them separately for later use;

[0043] (2) Prepare composite early-strength superplasticizer for use;

[0044] (3) Weigh red mud, steel slag, cement, metakaolin, and composite water-reducing early-strength agent, with a mass ratio of 46.5:38:10.5:4:1, and first mix the red mud, steel slag, cement, and metakaolin with an industrial mixer After uniformity, pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com