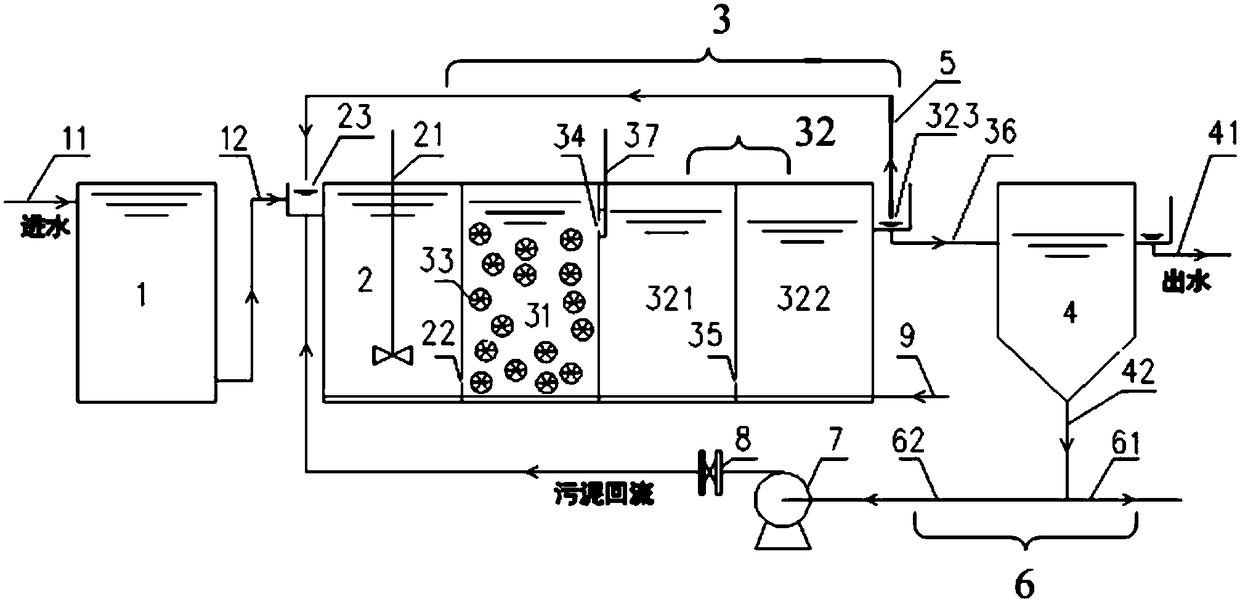

Nitrogen-containing organic wastewater treatment system and method thereof

A technology for organic waste water treatment and waste water, which is applied in biological water/sewage treatment, flotation water/sewage treatment, water/sewage multi-stage treatment, etc. Membrane is difficult to attach, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0166] A comprehensive sewage treatment project in a process park adopts the treatment system of the present invention to treat nitrogen-containing organic wastewater. First, put sludge in the anoxic reaction pool and aerobic reaction pool respectively, and select the sludge to be the nitrogen-containing organic wastewater to be treated. Wastewater cultured sludge. Then, the nitrogen-containing organic wastewater flows into the pretreatment tank through the first water inlet pipe for pretreatment, wherein, according to the water quality of the nitrogen-containing organic wastewater, the pretreatment process is selected, and the pretreatment process is selected from the oil separation process and the coagulation process. , sedimentation process, air flotation process, anaerobic process, etc. in one or more combinations. Then, the pretreated wastewater flows into the anoxic reaction tank through the first outlet pipe through the water inlet for anoxic treatment, and the agitator...

Embodiment 2

[0172] A comprehensive sewage treatment project in a process park adopts the treatment system of the present invention to treat nitrogen-containing coking wastewater, and first puts sludge from a coking plant wastewater treatment project into the anoxic reaction pool and the aerobic reaction pool respectively. Then, according to the water quality of the nitrogen-containing coking wastewater, the nitrogen-containing coking wastewater flows into the oil separation + air flotation + anaerobic combined pretreatment tank through the first water inlet pipe for pretreatment. Then, the pretreated wastewater flows into the anoxic reaction tank through the first outlet pipe through the water inlet for anoxic treatment, and the agitator in the anoxic reaction tank continues to stir with a stirring speed of 800r / min and a stirring power of 5w / m 3 . The anoxic treatment conditions in the anoxic reaction tank are: pH 8.0, reaction temperature 27°C, residence time 2h, sludge concentration 5g...

Embodiment 3

[0178] A comprehensive sewage treatment project in a process park adopts the treatment system of the present invention to treat nitrogen-containing organic wastewater. First, put sludge in the anoxic reaction pool and aerobic reaction pool respectively, and select the sludge to be the nitrogen-containing organic wastewater to be treated. Wastewater cultured sludge. Then, according to the water quality of the comprehensive sewage in the industrial park, the comprehensive sewage flows into the coagulation + sedimentation + anaerobic combined pretreatment tank through the first water inlet pipe for pretreatment. Then, the pretreated wastewater flows into the anoxic reaction tank through the first outlet pipe through the water inlet for anoxic treatment. The agitator in the anoxic reaction tank continues to stir with a stirring speed of 700r / min and a stirring power of 3w / m 3 . The anoxic treatment conditions in the anoxic reaction tank are: pH 7.4, reaction temperature 28°C, res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com