Nano sieve water treatment equipment and technology

A water treatment equipment and nano-sieve technology, applied in water/sewage treatment equipment, multi-stage water treatment, water/sewage treatment and other directions, can solve the problems of natural water body destruction, fragmentation, and difficulty in concentration, and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

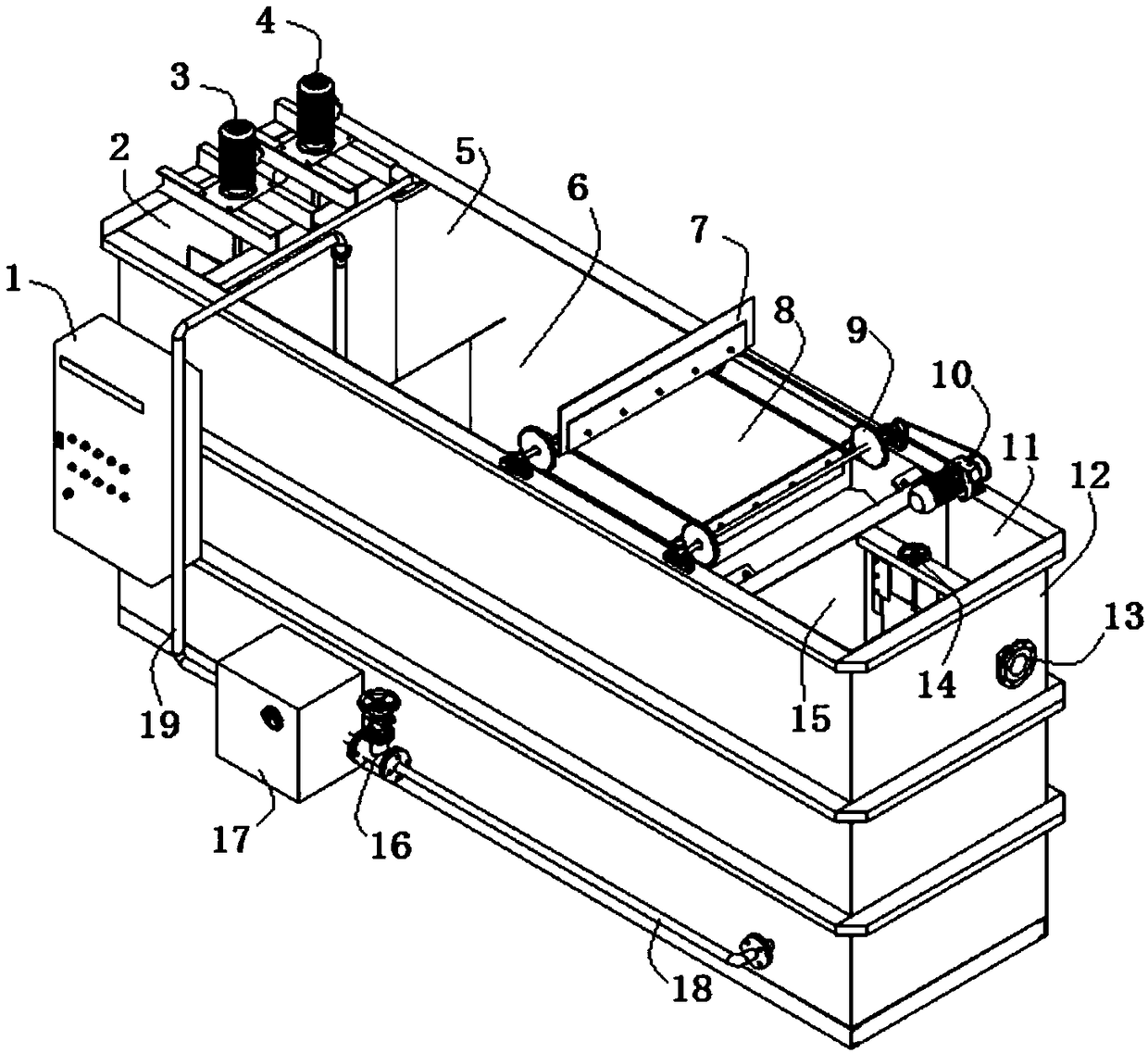

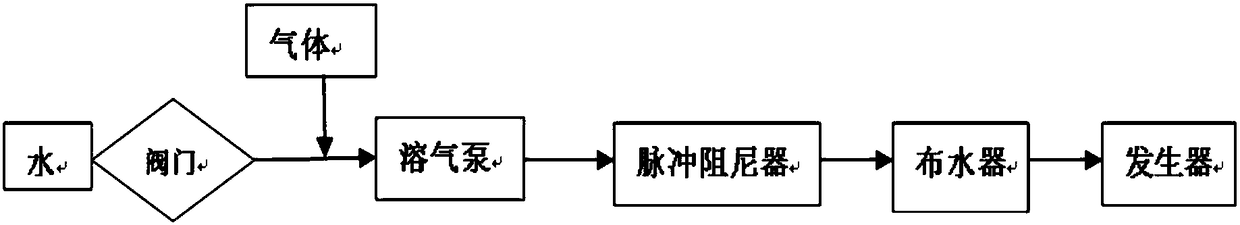

[0022] Below with the accompanying drawings ( Figure 1-Figure 2 ) to illustrate the present invention.

[0023] figure 1 It is a structural schematic diagram of a nano-sieve water treatment device implementing the present invention. figure 2 It is a schematic diagram of the structure of the micro-nano bubble generation system. Such as Figure 1 to Figure 2 Shown, a kind of nano-sieve water treatment equipment, comprises the casing 12 that has upper end face to be open, is integrated with agitation reaction zone (for example diversion groove 2, flocculation agitator 3 and coagulation agitator in described casing 12 4 constitute the stirring reaction zone), micro-nano bubble dissolution zone 5, nano-sieve flotation zone (for example, the first nano-sieve flotation zone 6 and the second nano-sieve flotation zone 8 constitute the nano-sieve flotation zone), scraping slag system (For example, the slag scraper 7, the transmission device 9 and the driving device 10 constitute t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com