Sintered NdFeB magnet and preparing method thereof

A NdFeB, magnet technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., to achieve the effect of uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

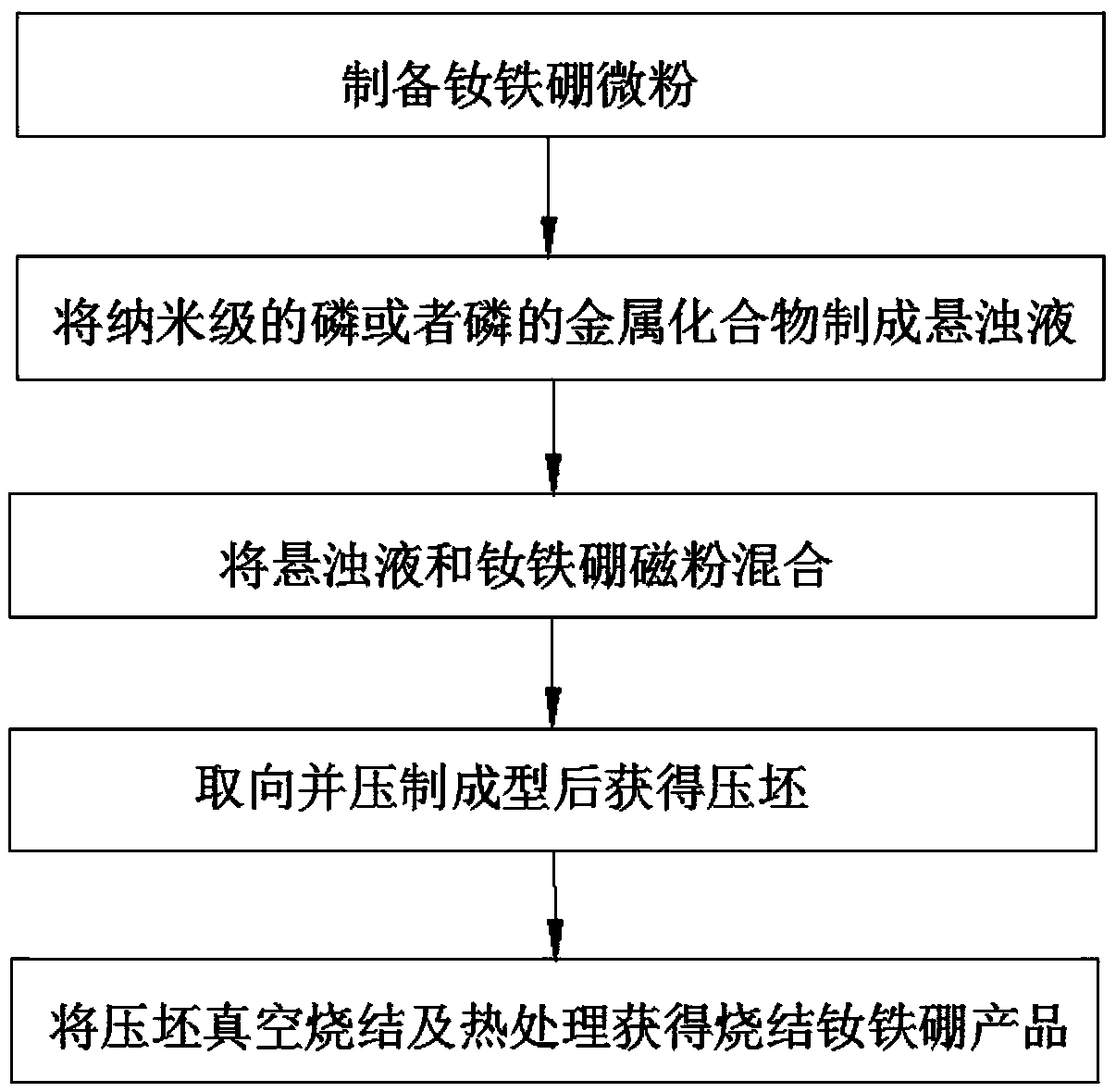

Method used

Image

Examples

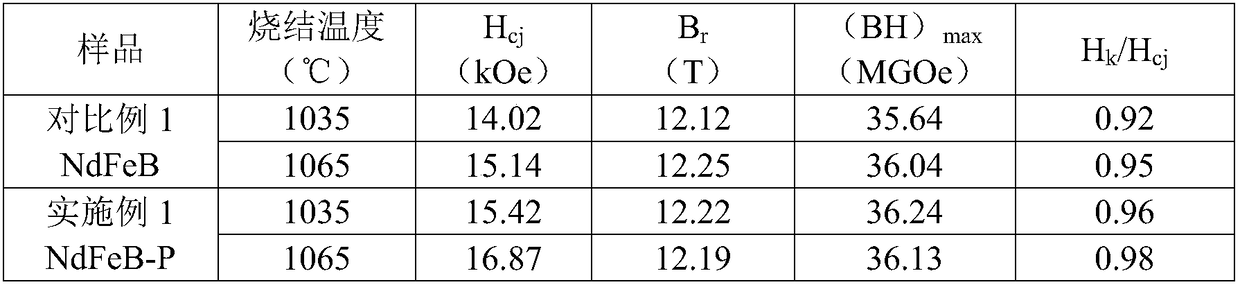

Embodiment 1

[0042] A method for preparing a sintered NdFeB magnet by improving the grain boundary phase of the magnet, the composition of the raw materials according to its weight percentage is as follows:

[0043] P: NdFeB powder = 0.5:100; the specific preparation steps are as follows:

[0044]Step 1: Prepare NdFeB powder with a powder particle size of D50 (50% passing particle size) = 3.5 μm by jet mill;

[0045] Step 2: Prepare a suspension of phosphorus with a particle size of 150-250 nm by mechanical crushing, rod milling and ball milling, with a concentration of 0.3 g / ml;

[0046] Step 3: Under the atmosphere of nitrogen or argon, according to the mass fraction of phosphorus of 0.5wt%, the prepared suspension is added to the mixing tank containing NdFeB powder, and mixed evenly on the three-dimensional mixer ;

[0047] Step 4: Orienting and pressing the mixed material under a protective atmosphere to obtain a compact;

[0048] Step 5: In a vacuum sintering furnace, select two gr...

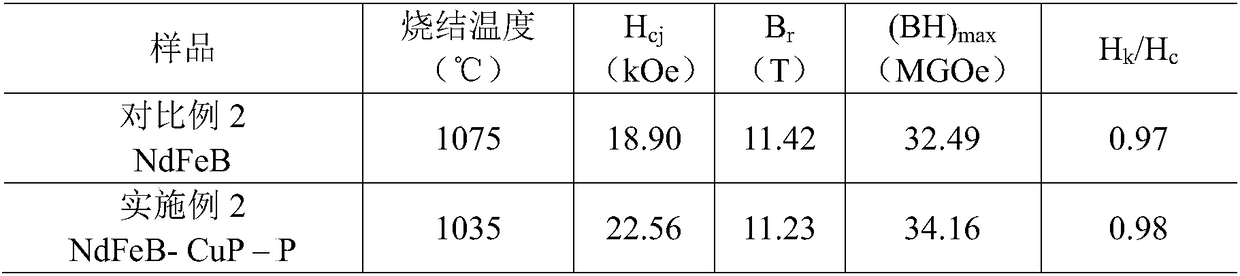

Embodiment 2

[0056] A method for preparing sintered NdFeB by improving the grain boundary phase of a magnet, the composition of raw materials according to the weight percentage is as follows:

[0057] CuP:P:NdFeB powder=0.8:0.2:100;

[0058] Concrete preparation steps are as follows:

[0059] Step 1: Prepare NdFeB powder with a powder particle size of D50=3.7 μm by jet mill;

[0060] Step 2: Prepare a suspension of CuP and P with a particle size of 300-400nm by mechanical crushing, rod milling and ball milling, the concentration of CuP is 0.4g / ml, and the concentration of P is 0.1g / ml;

[0061] Step 3: In an atmosphere of nitrogen or argon, according to the ratio of the mass fraction of CuP to 0.8wt% and the mass fraction of P to 0.2wt%, add the prepared suspension to the mixed material containing NdFeB powder In the tank, mix evenly on the three-dimensional mixer;

[0062] Step 4: Orienting and pressing the mixed powder in a protective atmosphere to obtain a compact;

[0063] Step 5: ...

Embodiment 3

[0070] A method for preparing sintered NdFeB by improving the grain boundary phase of a magnet, the composition of raw materials according to the weight percentage is as follows:

[0071] GaP: Co 2 P: CuP: NdFeB powder = 0.2:0.2:0.2:100;

[0072] Concrete preparation steps are as follows:

[0073] Step 1: Prepare NdFeB powder with a powder particle size of D50=3.5 μm by jet mill;

[0074] Step 2: Prepare GaP and Co with a particle size of 300-400nm by mechanical crushing, rod milling and ball milling 2 P, CuP suspension, the concentration is 0.4g / ml;

[0075] Step 3: Under nitrogen or argon atmosphere, according to GaP, Co 2 The mass fractions of P and CuP are all in the ratio of 0.2wt%, and the prepared suspension is added into a mixing tank equipped with NdFeB powder, and mixed evenly on a three-dimensional mixer;

[0076] Step 4: Orienting and pressing the mixed powder in a protective atmosphere to obtain a compact;

[0077] Step 5: Sinter in a vacuum sintering furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com