Pressurized water reactor nuclear power plant steel plate concrete structure module forming tool and forming process thereof

A steel plate concrete and structural module technology, which is applied in nuclear engineering, nuclear power generation, ceramic molding machines, etc., can solve the problems of difficult control of arc, easy deformation, complex structure of steel plate concrete structural modules, etc., to achieve accurate and convenient assembly and low risk The effect of construction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

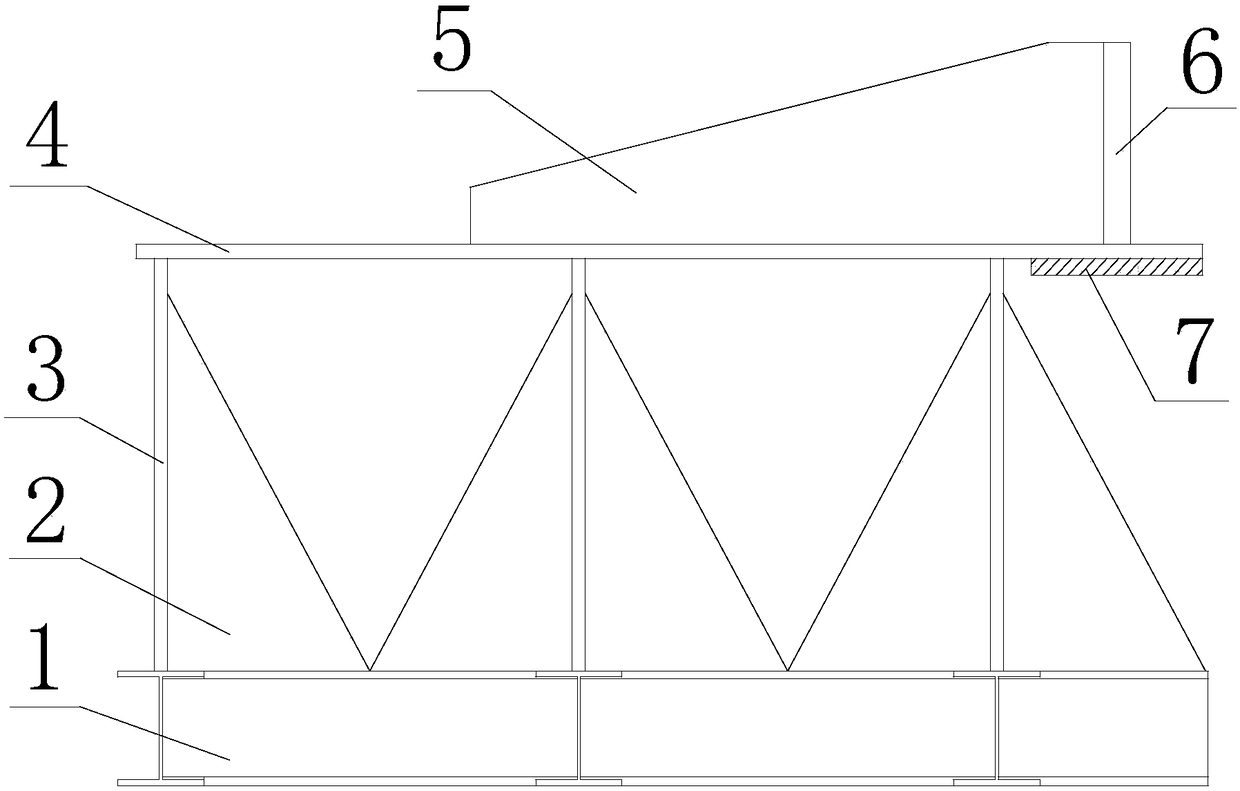

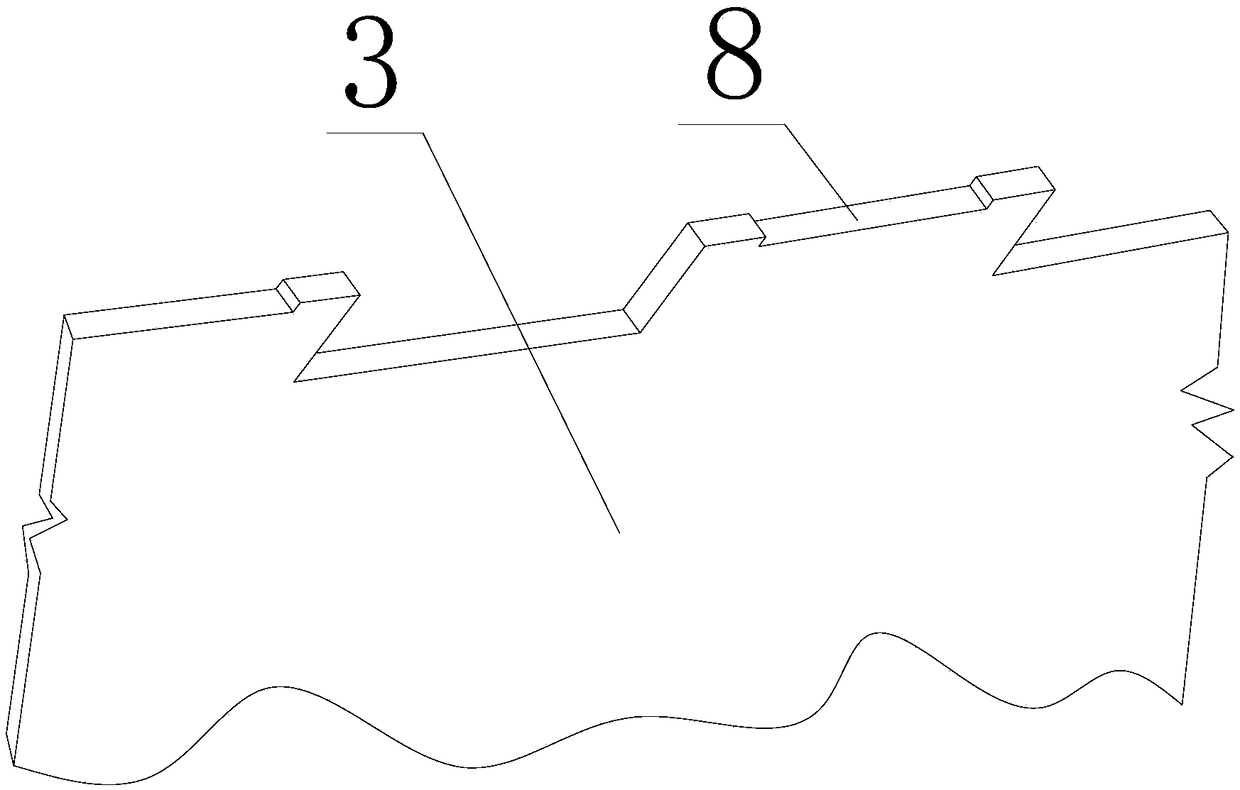

[0038] like Figure 1 to Figure 7 As shown, the forming tooling of the steel plate concrete structure module of the pressurized water reactor nuclear power plant uses H-shaped steel combined welding to form the underframe 1, and a number of parallel arc-shaped vertical plates 3 are fixed on the under-frame 1 by welding, and the arc-shaped plates 4 are arranged on The top of the arc-shaped riser 3 is subjected to force calculation. The radian of the arc-shaped riser 3 must be consistent with the design arc of the arc-shaped riser 4, so the top surface of the arc-shaped riser 3 is concaved to form a large number of notches 8, The arc-shaped plate 4 is arranged above the notch 8 and completely covers all the notches 8, so that the surface contact between the arc-shaped plate 4 and the arc-shaped vertical plate 3 can be changed into a point contact, which is beneficial to the fixing and forming of the arc-shaped plate 4 . The positioning between the arc-shaped plate 4 and the arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com