Connection structure of lower end of double-wave daylighting band joint and installation method thereof

A technology of connection structure and installation method, which is applied in building structure, roof, roof using flat/curved panels, etc., can solve problems such as unsatisfactory, obtrusive shape, waste of material and waterproof effect, and achieve stable support and good protection effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

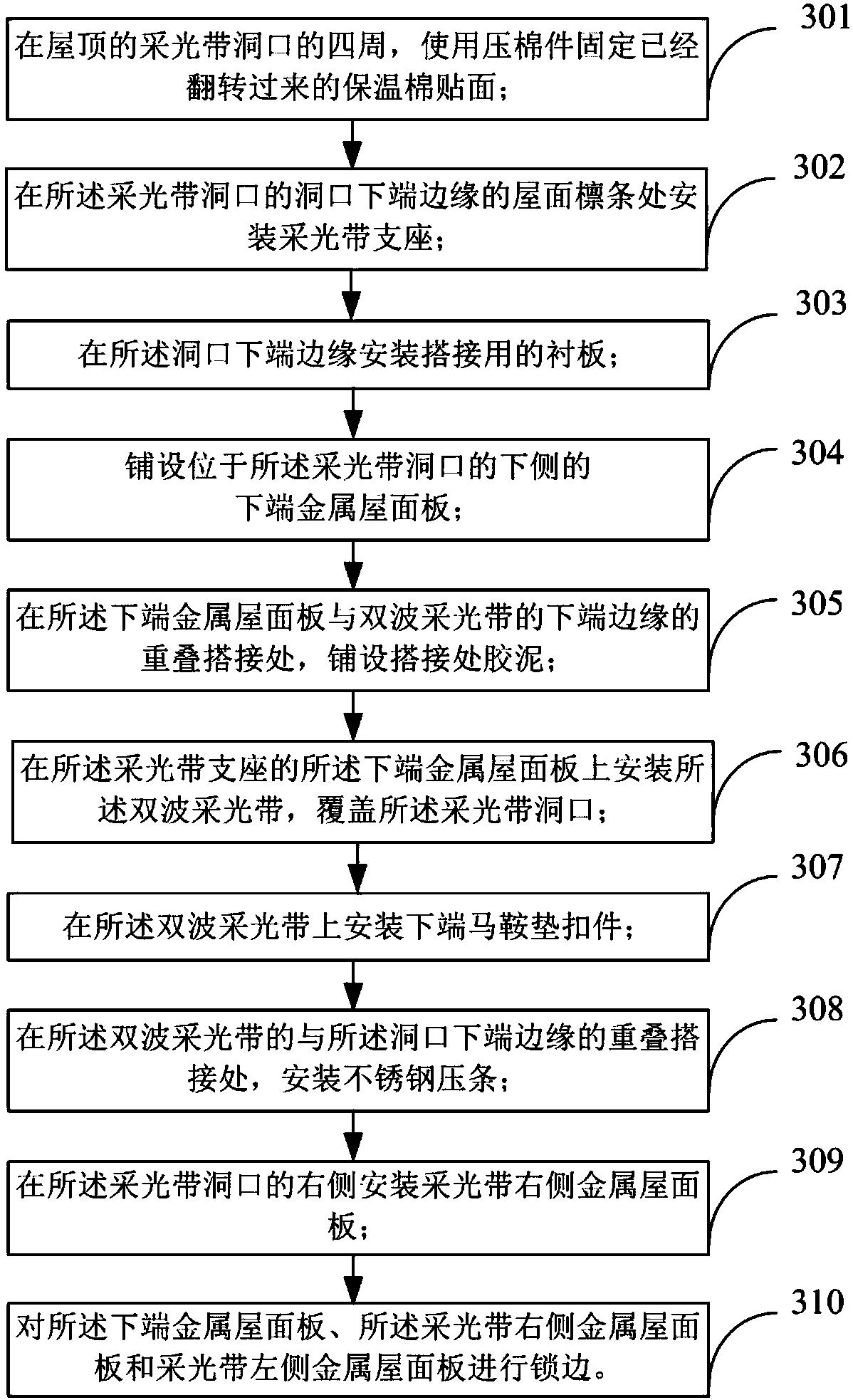

[0052] image 3 It is a flow chart of the installation method of the embodiment of the present invention.

[0053] Such as image 3 As shown, the embodiment of the present invention provides a method for installing the connection structure at the lower end of the node of the dual-wave lighting belt, including:

[0054] A method for installing a connection structure at the lower end of a node of a dual-wave lighting belt, comprising:

[0055] Step 301, around the opening of the daylighting belt on the roof, fix the overturned thermal insulation cotton veneer with a pressing piece;

[0056] Step 302, installing a lighting strip support at the roof purlin at the lower edge of the opening of the lighting strip opening;

[0057] Step 303, installing an overlapping liner on the lower edge of the hole;

[0058] Step 304, laying the lower metal roof panel on the lower side of the opening of the daylighting belt;

[0059] Step 305, laying glue on the overlapping joint between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com