A steel-plastic composite pipe joint and method thereof

A steel-plastic composite pipe and composite pipe head technology, applied in the direction of pipes/pipe joints/pipe fittings, flange connections, passing elements, etc., can solve the problems of pipes and joints falling off, water leakage, air leakage, etc., and achieve the effect of preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

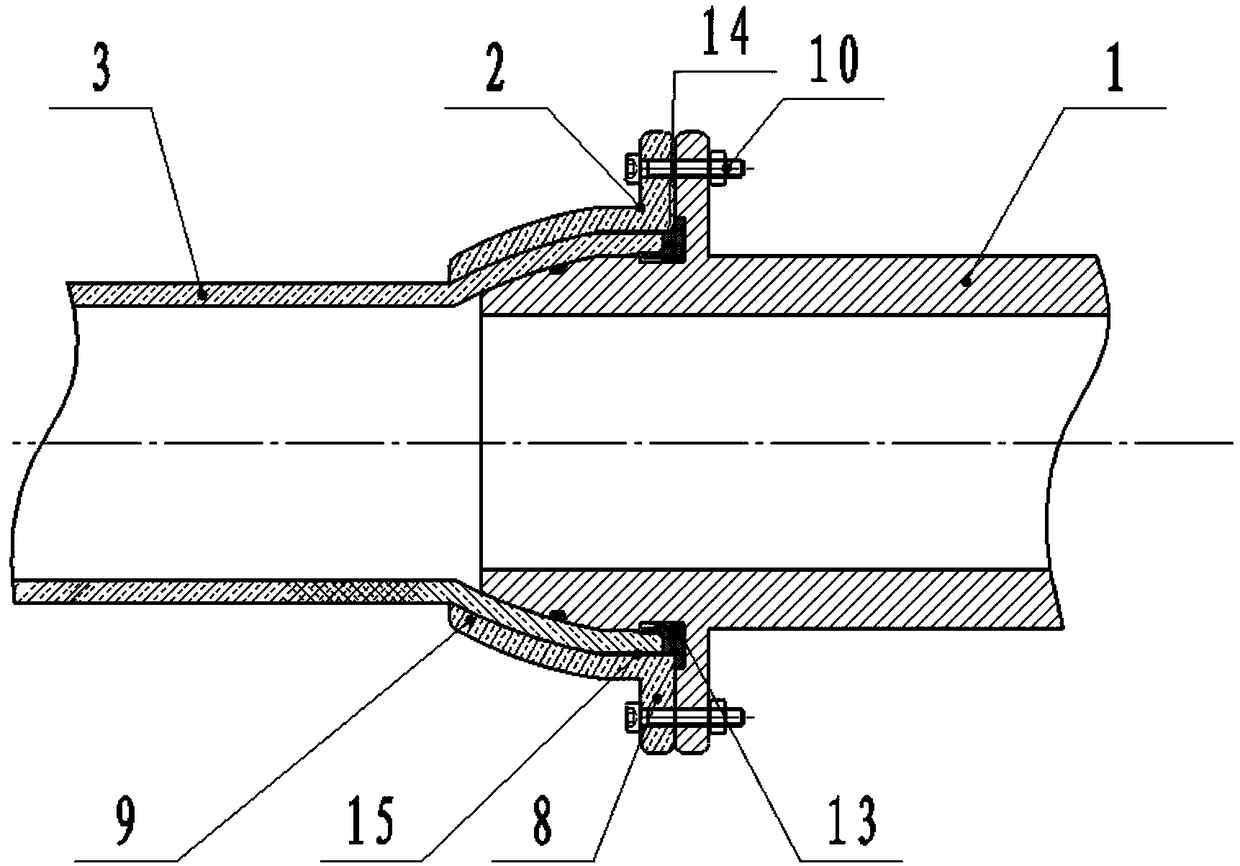

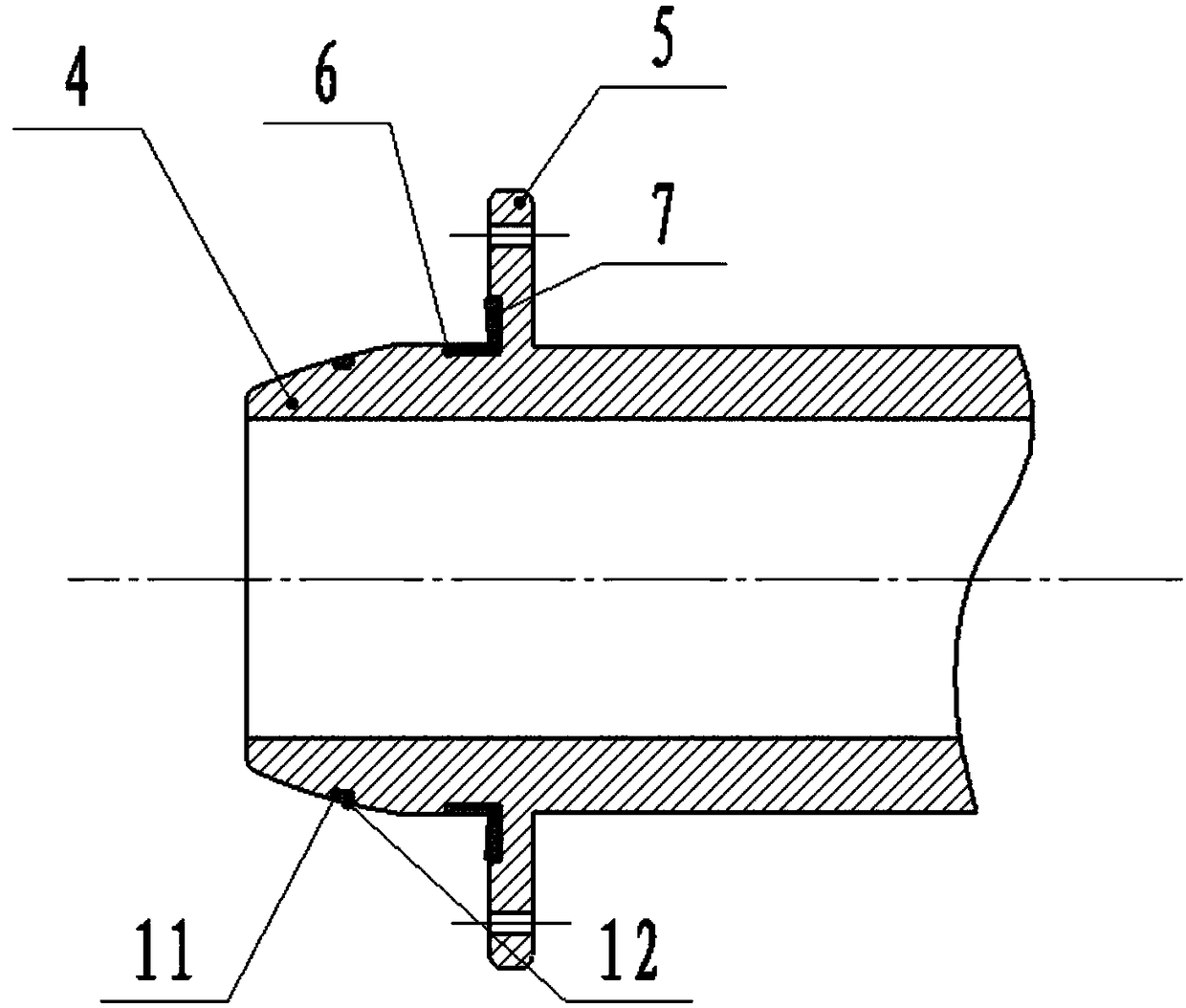

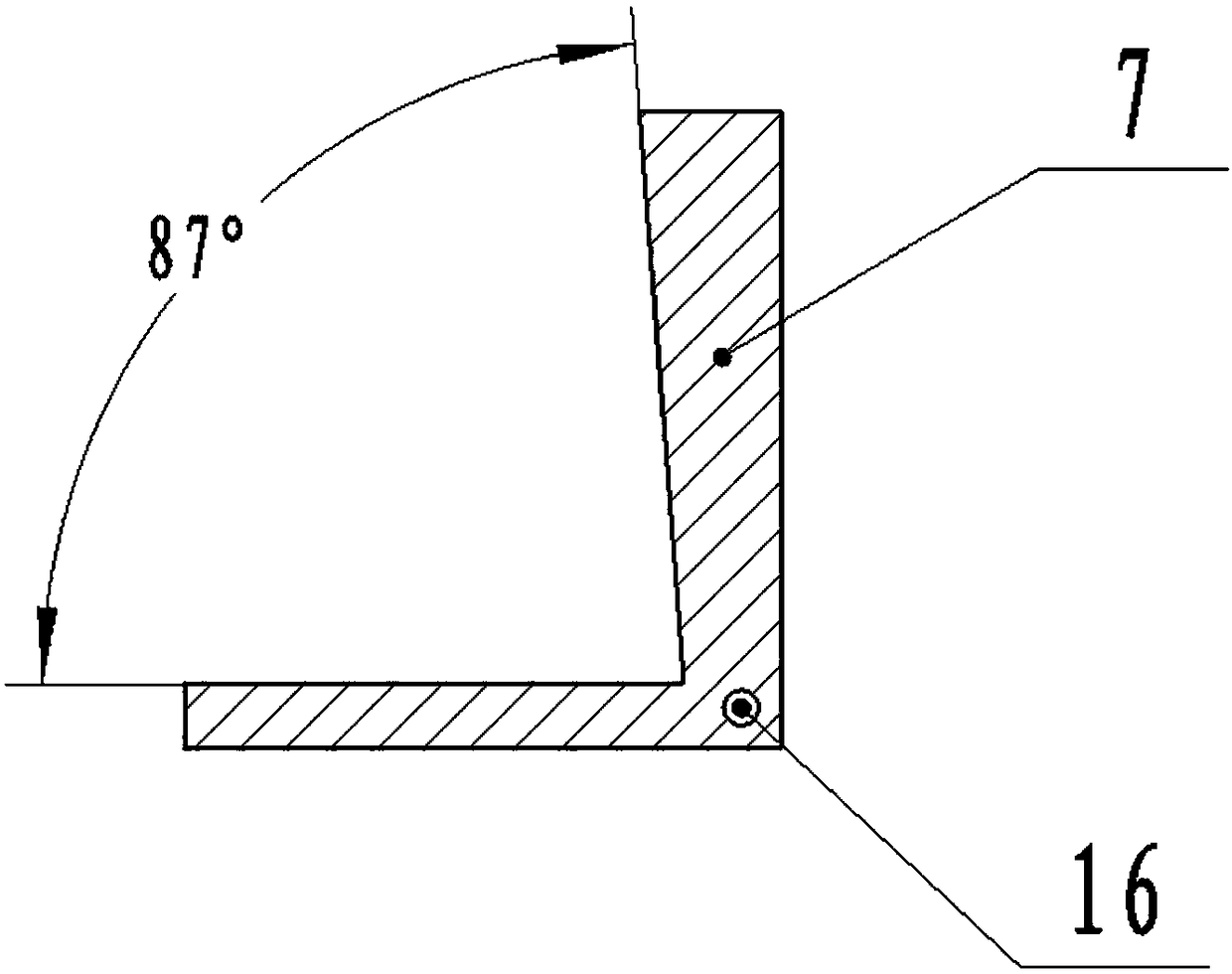

[0030] Such as Figure 1-3 As shown, a steel-plastic composite pipe joint of the present invention includes a connector body 1 and a connection compression set 2, both of which are made of forged cast iron and then clamped by machine, such as figure 1 shown, with figure 1 Only the connection structure of one end of the connector body 1 is shown. Since the connectors at both ends are the same, both ends of the connector body 1 are provided with a tapered joint 4 for inserting the steel-plastic composite pipe head 3, and the connector body inside the tapered joint 4 1 is provided with a first connecting flange 5, and a plurality of L-shaped grooves 6 are arranged around the angled surface between the outer surface of the first connecting flange 5 and the main body 1 of the connecting head, and an L-shaped tension block 7 is arranged in the L-shaped groove 6 The connection compression set 2 includes a second connection flange 8 and a compression sleeve 9, the compression sleeve ...

Embodiment 2

[0038] Such as Figure 1-3 As shown, a steel-plastic composite pipe connection method of the present invention comprises steps:

[0039] Step 1) Set the connection compression kit 2 on the steel-plastic composite pipe;

[0040] Step 2) The expansion of the steel-plastic composite pipe head 3 is matched with the tapered joint 4;

[0041] Step 3) Put a sealing ring 12 in the annular groove 11 on the tapered joint 4; put a sealing ring 14 at the angle between the outer surface of the first connecting flange 5 and the main body 1 of the connecting head;

[0042] Step 4) Put the flared steel-plastic composite pipe head 3 on the tapered joint 4 until the end surface of the steel-plastic composite pipe head 3 is squeezed on the sealing ring 14;

[0043] Step 5) Move the connection compression set 2 closer to the main body 1 of the connection head. After the connection compression set 2 is close to the flare of the steel-plastic composite pipe head 3, rotate the connection compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com