TiO2-WO3/rGO composite photoelectric energy storage material and preparation method and application of TiO2-WO3/rGO composite photoelectric energy storage material

An energy storage material, tio2-wo3 technology, applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of photogenerated electron transmission, capture and assisted storage, and improve the stability of electrochemical cycle resistance, good cathodic polarization, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

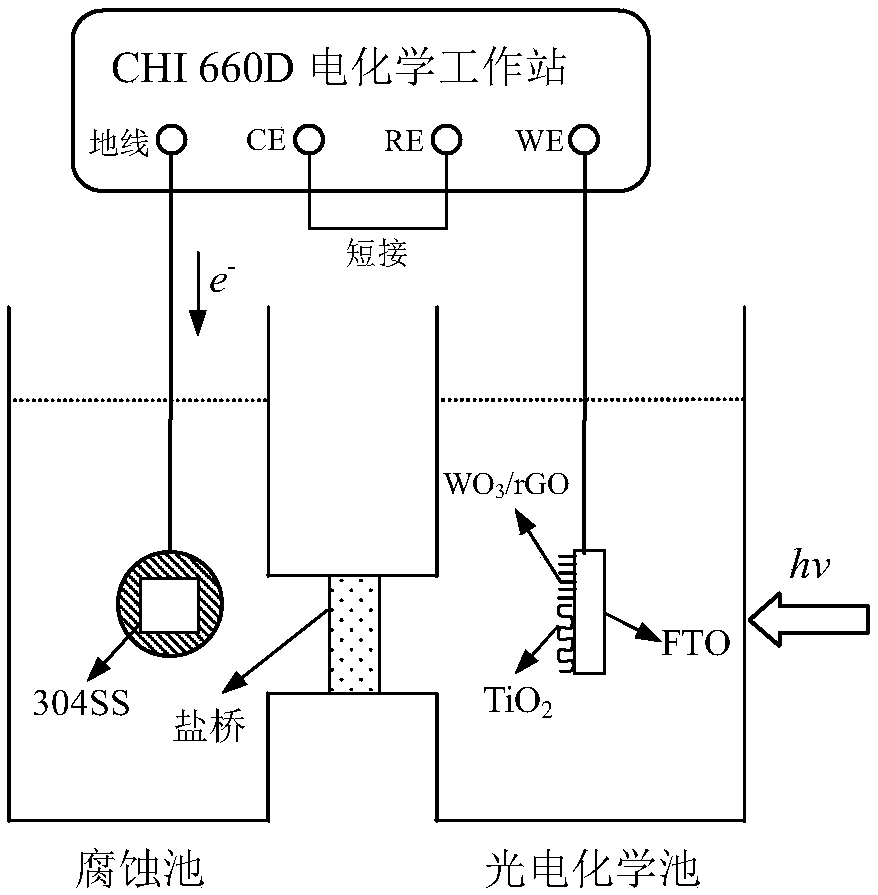

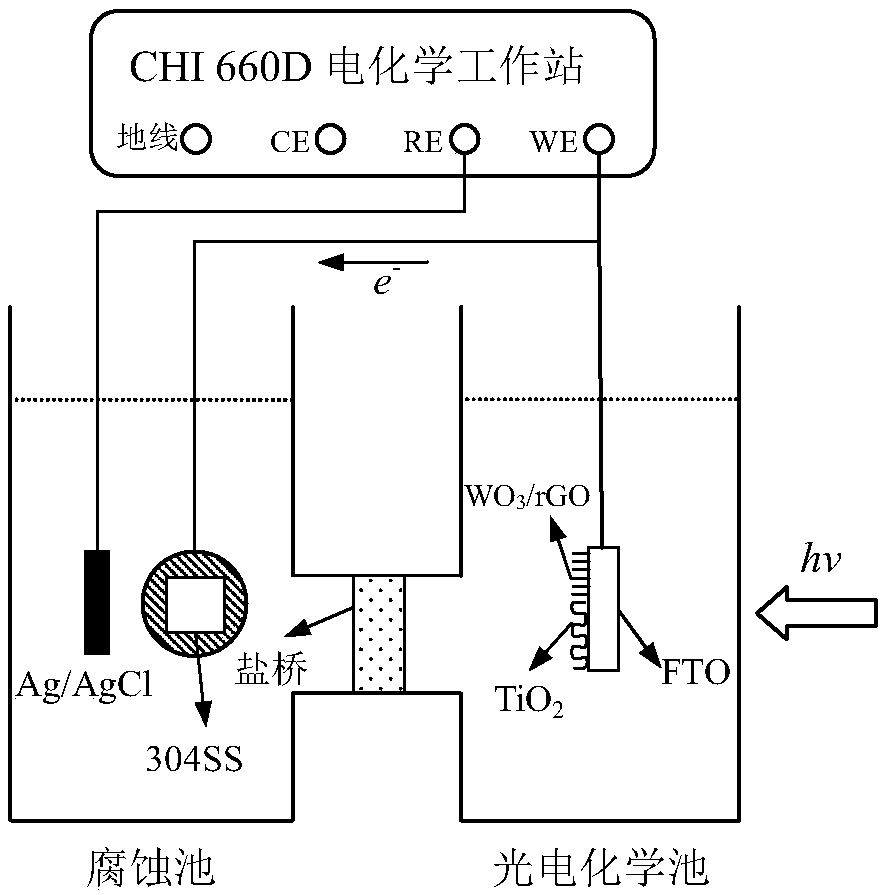

[0041] TiO for sustained photoelectrochemical cathodic protection 2 -WO 3 Preparation of / rGO composite photovoltaic energy storage photoanode:

[0042] 1) First, a certain amount of GO was added to ethanol and dispersed by ultrasonic vibration for 2 hours to form a stable dispersion of GO with a concentration of 0.5 mg / mL.

[0043] 2) WO 3 / rGO nanorod composites were prepared based on a simple solvothermal method and in situ growth method: the GO stable dispersion obtained in step 1) was added to the homogeneous solution (according to WO 3 0.1wt% of the mass), stirred evenly to form a homogeneous solution, then transferred to a polytetrafluoroethylene-lined stainless steel reactor, and centrifuged to collect the blue precipitate after hydrothermal heating at 180°C for 24 hours, and washed several times with ethanol . The product was ground in an agate mortar for further characterization.

[0044] Among them, the homogeneous solution is: under magnetic stirring, WCl 6 (...

Embodiment 2

[0054] TiO for sustained photoelectrochemical cathodic protection 2 -WO 3 Preparation of / rGO composite photovoltaic energy storage photoanode:

[0055] 1) First, a certain amount of GO was added to ethanol and dispersed by ultrasonic vibration for 2 hours to form a stable dispersion of GO with a concentration of 0.5 mg / mL.

[0056] 2) WO 3 / rGO nanorod composites were prepared based on a simple solvothermal method and in situ growth method: the GO stable dispersion obtained in step 1) was added to the homogeneous solution (according to WO 3 0.2wt% of the mass), stirred evenly to form a homogeneous solution, then transferred to a polytetrafluoroethylene-lined stainless steel reactor, and centrifuged to collect the blue precipitate after hydrothermal heating at 180°C for 24 hours, and washed several times with ethanol . The product was ground in an agate mortar for further characterization.

[0057] Among them, the homogeneous solution is: under magnetic stirring, WCl 6 (...

Embodiment 3

[0065] TiO for sustained photoelectrochemical cathodic protection 2 -WO 3 Preparation of / rGO composite photovoltaic energy storage photoanode:

[0066] 1) First, a certain amount of GO was added to ethanol and dispersed by ultrasonic vibration for 2 hours to form a stable dispersion of GO with a concentration of 0.5 mg / mL.

[0067] 2) WO 3 / rGO nanorod composites were prepared based on a simple solvothermal method and in situ growth method: the GO stable dispersion obtained in step 1) was added to the homogeneous solution (according to WO 3 0.3wt% of the mass), stirred evenly to form a homogeneous solution, then transferred to a polytetrafluoroethylene-lined stainless steel reactor, and centrifuged to collect the blue precipitate after hydrothermal heating at 180°C for 24 hours, and washed several times with ethanol . The product was ground in an agate mortar for further characterization.

[0068] Among them, the homogeneous solution is: under magnetic stirring, WCl 6 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com