Wear-resistant ceramic material as well as preparation method and application thereof

A technology of wear-resistant ceramics and ceramic micropowder, applied in the field of ceramics, can solve the problems of ceramic material damage, limited selection of 3D printing materials, poor wear resistance, etc., achieve good wear resistance, excellent mechanical properties and corrosion resistance, and prepare The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

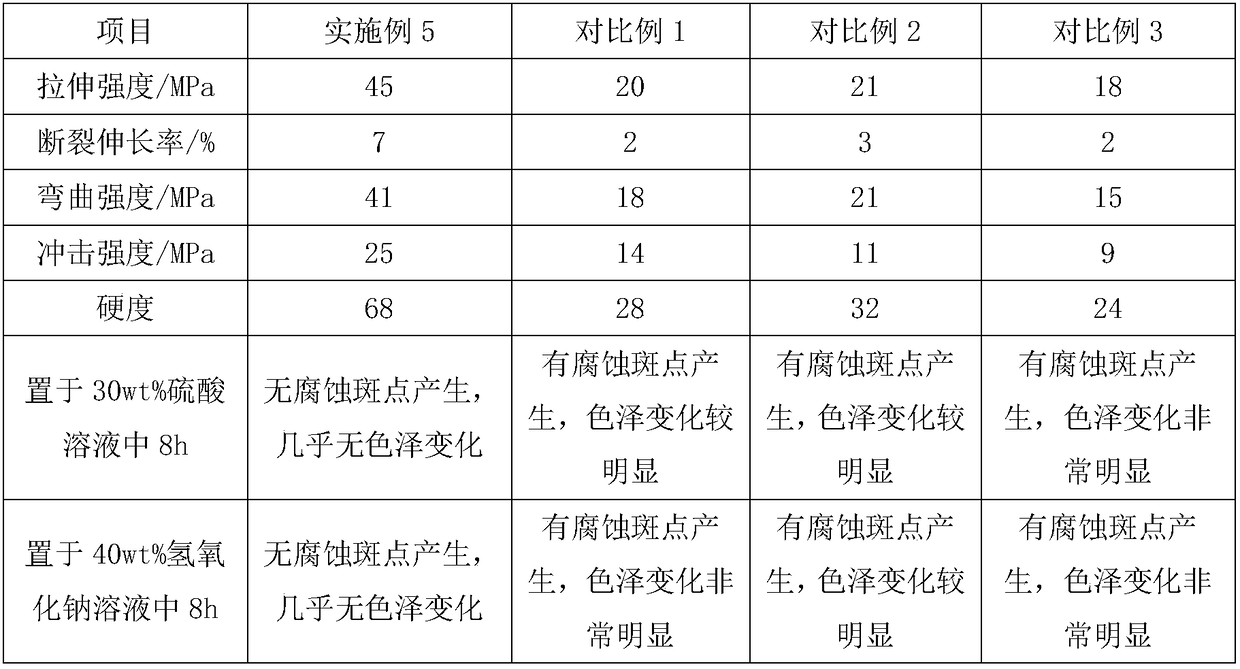

Examples

Embodiment 1

[0015] A wear-resistant ceramic material, comprising the following raw materials in parts by weight: 30 parts of nylon fiber, 10 parts of ceramic micropowder, 11 parts of dimethylaminoisopropanol, 14 parts of trisodium phosphate, 8 parts of cyanuric chloride, and mordenite powder 6 parts, 4 parts of isopropyl titanate, 2 parts of potassium aluminate.

[0016] A method for preparing a wear-resistant ceramic material, comprising the following steps: (1) mixing nylon fibers and ceramic micropowder, placing them at 180°C and mixing them uniformly, with a stirring speed of 350r / min; (2) adding phosphoric acid to the resultant obtained in the previous step Trisodium, mordenite powder and potassium aluminate, mix evenly at 210°C, stirring speed is 150r / min; mixing time is 15min; mixing time is 10min; (3) add isopropyl titanate to the result of the previous step , cyanuric chloride and dimethylaminoisopropanol, placed at 220 ° C and mixed evenly, the stirring speed is 100r / min; the mi...

Embodiment 2

[0018] A wear-resistant ceramic material, comprising the following raw materials in parts by weight: 55 parts of nylon fiber, 25 parts of ceramic micropowder, 17 parts of dimethylaminoisopropanol, 18 parts of trisodium phosphate, 16 parts of cyanuric chloride, and mordenite powder 9 parts, 9 parts of isopropyl titanate, 6 parts of potassium aluminate.

[0019] A method for preparing a wear-resistant ceramic material, comprising the following steps: (1) mixing nylon fibers and ceramic micropowder, placing them at 205°C and mixing them uniformly, with a stirring speed of 500r / min; (2) adding phosphoric acid to the resultant in the previous step Trisodium, mordenite powder and potassium aluminate, mix evenly at 220°C, stirring speed is 220r / min; mixing time is 30min; mixing time is 20min; (3) Add isopropyl titanate to the result of the previous step , cyanuric chloride and dimethylaminoisopropanol, placed at 235 ° C and mixed evenly, the stirring speed is 200r / min; the mixing tim...

Embodiment 3

[0021] A wear-resistant ceramic material, comprising the following raw materials in parts by weight: 42 parts of nylon fiber, 16 parts of ceramic micropowder, 13 parts of dimethylaminoisopropanol, 16 parts of trisodium phosphate, 11 parts of cyanuric chloride, and mordenite powder 8 parts, 6 parts of isopropyl titanate, 4 parts of potassium aluminate.

[0022] A method for preparing a wear-resistant ceramic material, comprising the following steps: (1) mixing nylon fibers and ceramic micropowder, placing them at 190°C and mixing them uniformly, with a stirring speed of 400r / min; (2) adding phosphoric acid to the resultant obtained in the previous step Trisodium, mordenite powder and potassium aluminate, mix evenly at 215°C, stirring speed is 170r / min; mixing time is 20min; mixing time is 15min; (3) add isopropyl titanate to the result of the previous step , cyanuric chloride and dimethylaminoisopropanol, placed at 230 ° C and mixed evenly, the stirring speed is 160r / min; the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com