Magnesite material and preparation method thereof

A magnesite material and raw material technology, applied in the field of magnesite material and its preparation, can solve problems such as poor water resistance, easy to bloom, poor mechanical properties, etc., to avoid deformation and cracks, reduce bleeding, and avoid moisture absorption and return The effect of halogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

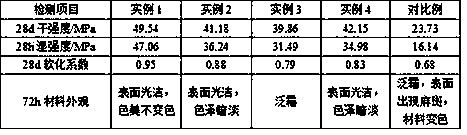

Examples

example 1

[0023]Add sodium alginate and water into the beaker at a mass ratio of 1:100, stir and mix with a glass rod for 30 minutes, let it stand for swelling for 4 hours, and then move the beaker into a magnetic stirrer with a digital speed measurement and constant temperature at a temperature of 100°C and a speed of 500r Under the condition of heating and stirring for 50 min, the sodium alginate solution is obtained; the walnut shells are put in a ball mill, pulverized by ball milling, and passed through an 80-mesh sieve to obtain walnut shell powder; the walnut shell powder is placed in a carbonization furnace, and Fill the furnace with nitrogen gas at 60mL / min, and at a temperature of 650°C, under the condition of nitrogen protection, keep warm and carbonize for 2 hours, and then cool down to room temperature with the furnace to obtain carbonized walnut shell powder; mix the carbonized walnut shell powder with saturated hydrogen The calcium oxide solution was placed in a three-necke...

example 2

[0025] Add sodium alginate and water into the beaker at a mass ratio of 1:100, stir and mix with a glass rod for 30 minutes, let it stand for swelling for 4 hours, and then move the beaker into a magnetic stirrer with a digital speed measurement and constant temperature at a temperature of 100°C and a speed of 500r Under the condition of heating and stirring for 50 min, the sodium alginate solution is obtained; the walnut shells are put in a ball mill, pulverized by ball milling, and passed through an 80-mesh sieve to obtain walnut shell powder; the walnut shell powder is placed in a carbonization furnace, and Fill the furnace with nitrogen gas at 60mL / min, and at a temperature of 650°C, under the condition of nitrogen protection, keep warm and carbonize for 2 hours, and then cool down to room temperature with the furnace to obtain carbonized walnut shell powder; mix the carbonized walnut shell powder with saturated hydrogen The calcium oxide solution was placed in a three-neck...

example 3

[0027] Add sodium alginate and water into the beaker at a mass ratio of 1:100, stir and mix with a glass rod for 30 minutes, let it stand for swelling for 4 hours, and then move the beaker into a magnetic stirrer with a digital speed measurement and constant temperature at a temperature of 100°C and a speed of 500r Under the condition of heating and stirring for 50 min, the sodium alginate solution is obtained; the walnut shells are put in a ball mill, pulverized by ball milling, and passed through an 80-mesh sieve to obtain walnut shell powder; the walnut shell powder is placed in a carbonization furnace, and Fill the furnace with nitrogen gas at 60mL / min, and at a temperature of 650°C, under the condition of nitrogen protection, keep warm and carbonize for 2 hours, and then cool down to room temperature with the furnace to obtain carbonized walnut shell powder; mix the carbonized walnut shell powder with saturated hydrogen The calcium oxide solution was placed in a three-neck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com