A kind of polymerizable hyperbranched surfactant and preparation method thereof

A surfactant, hyperbranched polymer technology, applied in chemical instruments and methods, drilling compositions, chemical/physical processes, etc. problem, to achieve the effect of low critical micelle concentration, good shear resistance, and significant emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of hyperbranched surfactants

[0034] (1) Preparation of intermediates

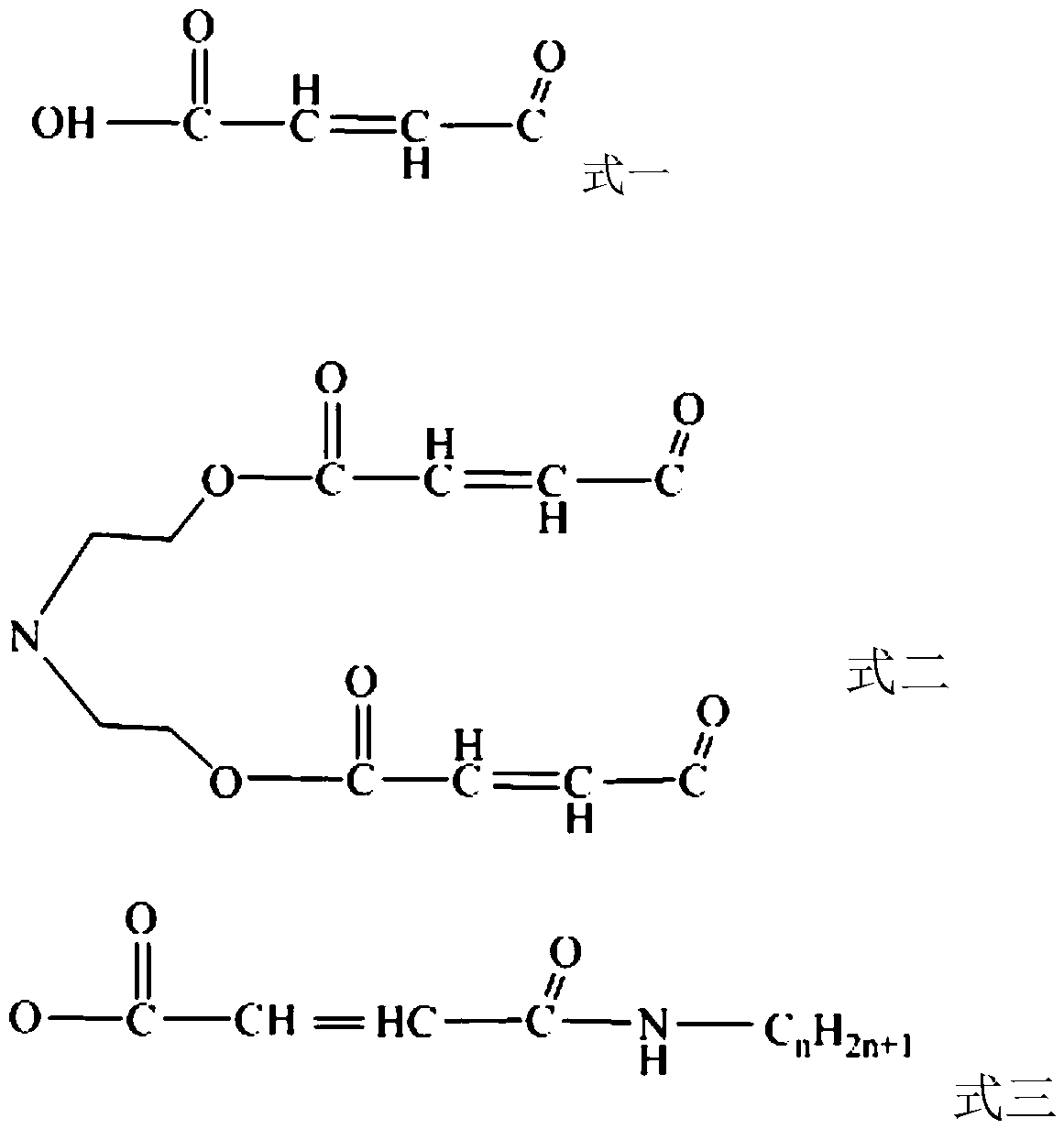

[0035] Add maleic anhydride, aliphatic amine and chloroform into the three-necked flask according to the molar ratio of 1.05-1.2:1:20, stir for 30 minutes in an ice-water bath, then warm up to room temperature and keep for 2-5 hours until the acid value of the reaction system changes ≤0.5mgKOH / g when the reaction is over. After the reaction is finished, the solvent is evaporated at low temperature, the reaction product is dissolved in acetone to remove excess maleic anhydride, and vacuum-dried to obtain an intermediate of a carboxylic acid amide containing an unsaturated double bond, its structure is shown in formula a;

[0036]

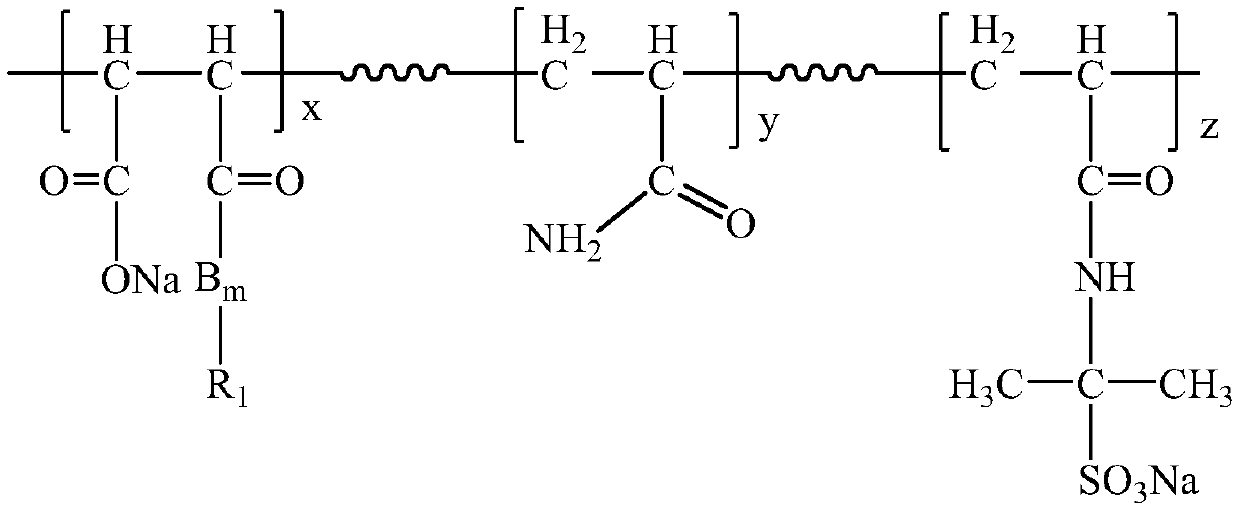

[0037] (2) Preparation of hyperbranched macromolecules

[0038] Add maleic anhydride and diethanolamine into the three-necked flask according to the molar ratio of 1.05-1.2:1, pass N under ice-water bath 2 Under normal circumstances, after stirring f...

Embodiment 2

[0050] 1. Preparation of hyperbranched surfactants

[0051] (1) Preparation of intermediates

[0052] Add maleic anhydride, aliphatic amine and chloroform into the three-necked flask according to the molar ratio of 1.05-1.2:1:20, stir for 30 minutes in an ice-water bath, then warm up to room temperature and keep for 2-5 hours until the acid value of the reaction system changes ≤0.5mgKOH / g when the reaction is over. After the reaction is finished, the solvent is evaporated at low temperature, the reaction product is dissolved in acetone to remove excess maleic anhydride, and vacuum-dried to obtain an intermediate of a carboxylic acid amide containing an unsaturated double bond, its structure is shown in formula a;

[0053]

[0054] (2) Preparation of hyperbranched macromolecules

[0055] Add maleic anhydride and diethanolamine into the three-necked flask according to the molar ratio of 1.05-1.2:1, pass N under ice-water bath 2 Under normal circumstances, after stirring f...

Embodiment 3

[0067] 1. Preparation of hyperbranched surfactants

[0068] (1) Preparation of intermediates

[0069] Add maleic anhydride, aliphatic amine and chloroform into the three-necked flask according to the molar ratio of 1.05-1.2:1:20, stir for 30 minutes in an ice-water bath, then warm up to room temperature and keep for 2-5 hours until the acid value of the reaction system changes ≤0.5mgKOH / g when the reaction is over. After the reaction is finished, the solvent is evaporated at low temperature, the reaction product is dissolved in acetone to remove excess maleic anhydride, and vacuum-dried to obtain an intermediate of a carboxylic acid amide containing an unsaturated double bond, its structure is shown in formula a;

[0070]

[0071] (2) Preparation of hyperbranched macromolecules

[0072] Add maleic anhydride and diethanolamine into the three-necked flask according to the molar ratio of 1.05-1.2:1, pass N under ice-water bath 2 Under normal circumstances, after stirring f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com