Heat-not-burn cigarette smoke cooling material and application thereof

A heat-not-burn, cigarette smoke technology, applied in applications, smoker supplies, tobacco, etc., can solve the problems of reducing the smoking experience and trapping smoke, so as to avoid heat shrinkage, low smoke retention rate, and good cooling effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

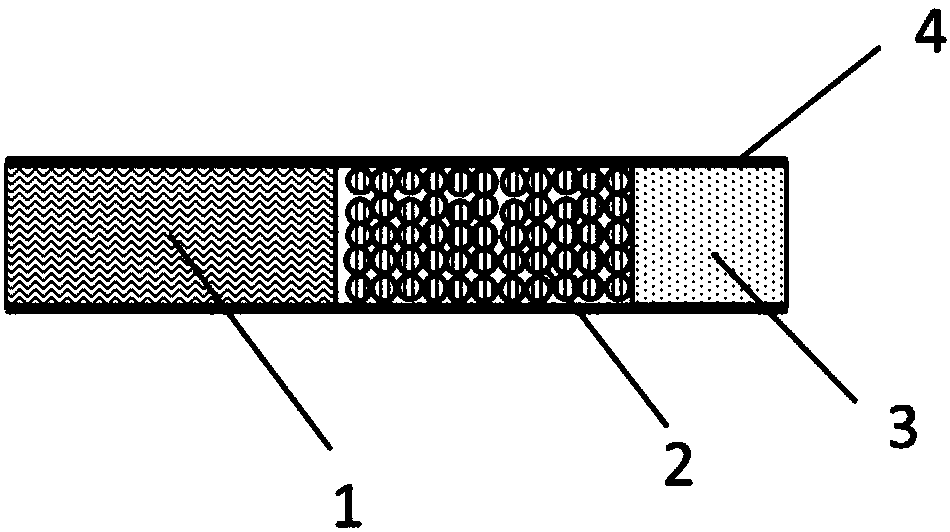

[0035] Weigh 70g of polylactic acid and feed it into a screw extruder to melt, extrude and granulate to obtain 1-2mm cooling granules. Utilize this cooling particle to prepare cooling nozzle stick ( figure 1 ), the circumference of the cigarette is 24.0mm, the length of the tobacco section 1 is 15mm, the length of the polylactic acid particle section 2 is 12mm, and the length of the solid filter tip 3 is 8mm. Smoking in ISO mode was carried out on a single-hole smoking machine (puffing time was 2 s, puffing interval was 58 s, and the puffing volume was 35 mL per puff), and the smoke temperature of the filter was detected online by a cigarette gas phase temperature detector. for 47 o C, 10% shrinkage.

Embodiment 2

[0037] Take by weighing 70g polylactic acid, 5g graphene, 8g calcium carbonate whisker, 12g calcium nitrate hydrate and 5g aluminum powder (diameter is 0.5mm) and mix evenly, send into the screw extruder and melt and extrude granulation, obtain 1~ 2mm cooling particles. Utilize this cooling particle to prepare cooling nozzle stick ( figure 1 ), the circumference of the cigarette is 23.0mm, the length of the tobacco section 1 is 14mm, the length of the modified polylactic acid particle cooling section 5 is 15mm, and the length of the solid filter tip 3 is 8mm. Smoking in ISO mode was carried out on a single-hole smoking machine (puffing time was 2 s, puffing interval was 58 s, and the puffing volume was 35 mL per puff), and the smoke temperature of the filter was detected online by a cigarette gas phase temperature detector. The test results show that compared with Example 1, the composite filter with phase change material has a significant effect on reducing the smoke tempera...

Embodiment 3

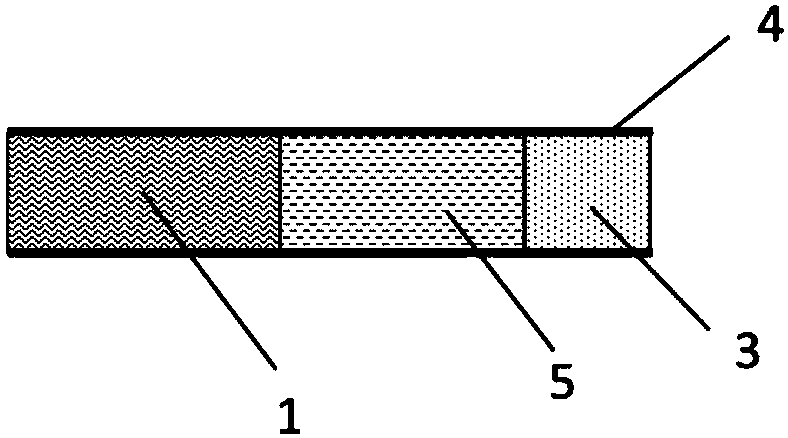

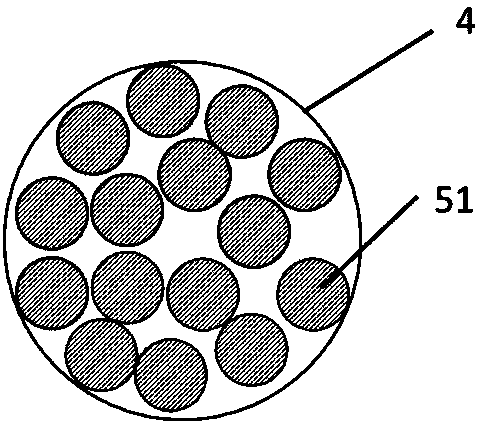

[0039] Weigh 65g of polylactic acid, 7g of montmorillonite, 11g of carbon fiber, 10g of sodium sulfate hydrate, and 7g of copper powder, mix them evenly, and send them into a screw extruder for melt extrusion and granulation to obtain a cooling line with a diameter of 0.5mm. The cooling wires are bundled to obtain the cooling nozzle stick ( figure 2), the circumference of the cigarette is 23.0mm, the length of the tobacco section 1 is 14mm, the length of the modified polymer fiber cooling section 5 is 15mm, and the length of the solid filter tip 3 is 8mm. Smoking in ISO mode was carried out on a single-hole smoking machine (puffing time was 2 s, puffing interval was 58 s, and the puffing volume was 35 mL per puff), and the smoke temperature of the filter was detected online by a cigarette gas phase temperature detector. The test results show that compared with Example 1, the composite filter with phase change material has a significant effect on reducing the smoke temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com