Yogurt and its preparation method

A technology of yogurt, distarch phosphate, applied in the direction of milk preparations, other dairy products, bacteria used in food preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

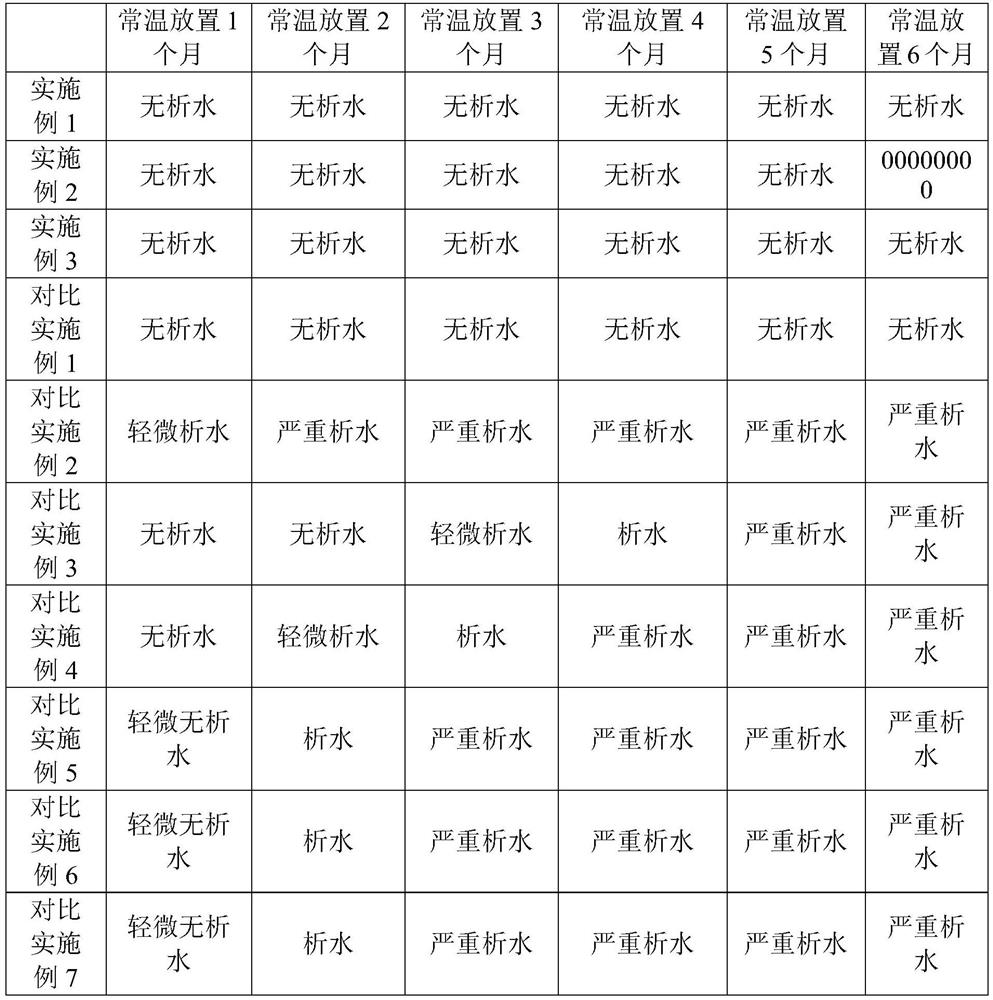

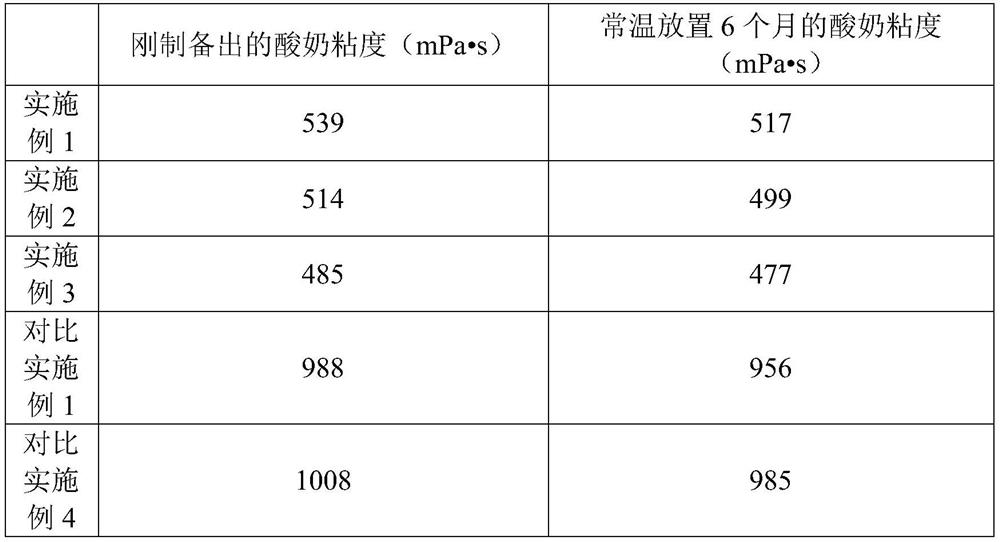

Examples

Embodiment 1

[0027] 1. Raw materials

[0028] 925.98 parts by weight of raw milk, 70 parts by weight of white granulated sugar, 3 parts by weight of acetylated distarch phosphate, 0.02 parts by weight of diacetyl tartrate mono-diglycerides, 0.1 parts by weight of gellan gum, 0.8 parts by weight of low-methoxy pectin, 0.04 parts by weight of high methoxy pectin, 0.02 parts by weight of konjac gum, and 0.04 parts by weight of gelatin.

[0029] 2. Process

[0030] When the temperature of 60% raw milk is raised to 40°C, start feeding (white sugar, acetylated distarch phosphate, diacetyl tartrate mono-diglyceride, gellan gum, low methoxyl pectin, high methoxyl pectin, konjac gum, gelatin), circulate and stir for 10 minutes, and then add the remaining raw milk. Carry out homogenization, homogenization pressure primary pressure 120bar, secondary pressure 60bar, after the homogenization is completed, sterilize, the sterilization temperature is 110 ℃, the sterilizing time is 5s and then sterilize...

Embodiment 2

[0032] 1. Raw materials

[0033] 914.78 parts by weight of raw milk, 75 parts by weight of white granulated sugar, 8 parts by weight of acetylated distarch phosphate, 0.3 parts by weight of diacetyl tartrate mono-diglyceride, 0.5 parts by weight of gellan gum, 1.2 parts by weight of low-methoxy pectin, 0.06 parts by weight of high methoxy pectin, 0.06 parts by weight of konjac gum, and 0.1 parts by weight of gelatin.

[0034] 2. Process

[0035] When 60% raw milk is warmed up to 40-55°C, start feeding (white sugar, acetylated distarch phosphate, diacetyl tartrate mono-diglyceride, gellan gum, low-methoxyl pectin, high-methoxyl pectin) Glue, konjac gum, gelatin), circulate and stir for 15 minutes, then add the remaining raw milk. Carry out homogenization, homogenization pressure primary pressure 130bar, secondary pressure 70bar, after homogenization is completed, sterilize, the sterilization temperature is 110 degrees Celsius, the sterilization time is 10s and then sterilize,...

Embodiment 3

[0037] 1. Raw materials

[0038] 896.55 parts by weight of raw milk, 85 parts by weight of white granulated sugar, 15 parts by weight of acetylated distarch phosphate, 0.5 parts by weight of diacetyl tartrate mono-diglycerides, 0.8 parts by weight of gellan gum, 1.8 parts by weight of low-methoxy pectin, 0.08 parts by weight of high methoxy pectin, 0.09 parts by weight of konjac gum, and 0.18 parts by weight of gelatin.

[0039] 2. Process

[0040] When the temperature of 60% raw milk is raised to 55°C, start feeding (white sugar, acetylated distarch phosphate, diacetyl tartrate mono-diglyceride, gellan gum, low methoxyl pectin, high methoxyl pectin, konjac gum, gelatin), circulate and stir for 20 minutes, and then add the remaining raw milk. Carry out homogenization, homogenization pressure primary pressure 140bar, secondary pressure 80bar, after homogenization is completed, sterilize, sterilization temperature is 110 degrees Celsius, sterilization time is 15s and then ster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com