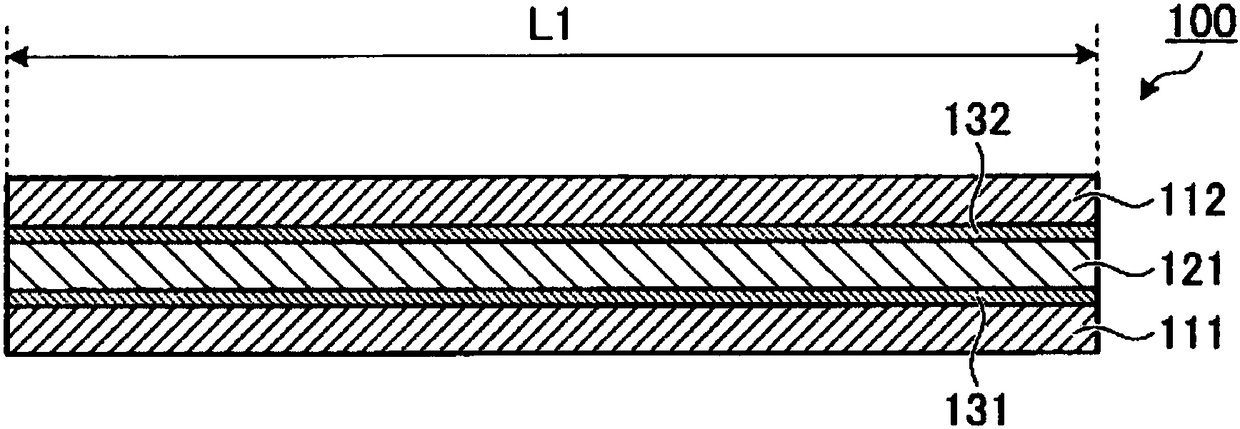

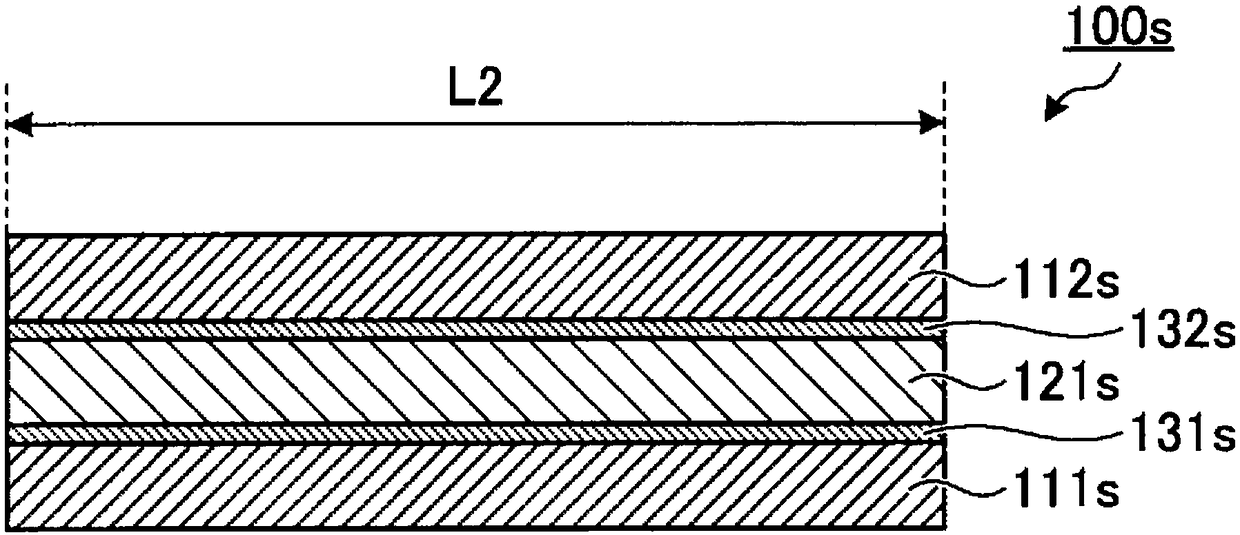

Phase difference film and production method for same

A technology of retardation film and manufacturing method, applied in chemical instruments and methods, instruments, polarizing elements, etc., can solve problems such as difficulty in manufacturing retardation film, and achieve the effects of small NZ coefficient, easy manufacture and high visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

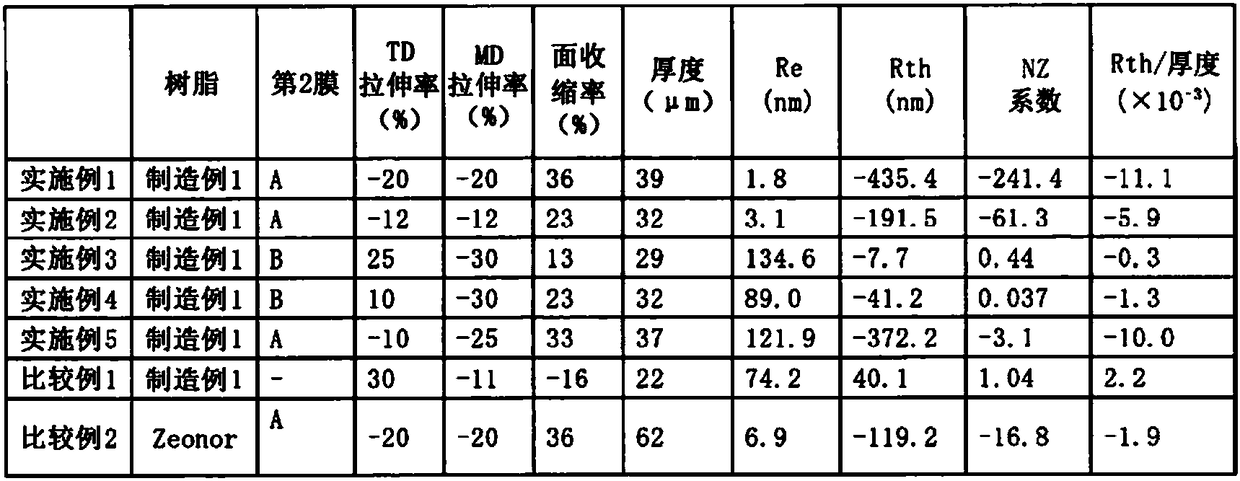

[0200] Examples are shown below to describe the present invention in detail. However, the present invention is not limited to the examples shown below, and can be arbitrarily modified and implemented within a range not departing from the claimed scope of the present invention and a scope equivalent thereto.

[0201] In the following description, unless otherwise stated, "%" and "part" which show an amount are based on weight. In addition, the operations described below were performed under conditions of normal temperature and normal pressure unless otherwise specified.

[0202] [Evaluation method]

[0203] [Measurement method of weight average molecular weight and number average molecular weight]

[0204] The weight-average molecular weight and number-average molecular weight of the polymer were measured as polystyrene-equivalent values using a gel permeation chromatography (GPC) system ("HLC-8320" manufactured by To soh Co., Ltd.). In the measurement, an H-type column (m...

manufacture example 1

[0213] [Production Example 1: Production of hydrogenated product of ring-opening polymer of dicyclopentadiene]

[0214] After sufficiently drying the metal pressure-resistant reactor, nitrogen substitution was performed. In this metal pressure-resistant reactor, 154.5 parts of cyclohexane and 42.8 parts of dicyclopentadiene (with an internal type content rate of 99% or more) in a 70% cyclohexane solution (in the form of dicyclopentadiene) were added. The amount of diene is 30 parts) and 1.9 parts of 1-hexene, heated to 53°C.

[0215] A solution was prepared by dissolving 0.014 parts of tungsten tetrachloride phenylimide (tetrahydrofuran) complex in 0.70 parts of toluene. To this solution was added 0.061 parts of a 19% diethylaluminum ethoxide / n-hexane solution, and stirred for 10 minutes to prepare a catalyst solution.

[0216] The catalyst solution is added into a pressure-resistant reactor to initiate ring-opening polymerization. Then, it was made to react for 4 hours, ke...

manufacture example 2-1

[0227] [Manufacture Example 2-1: Manufacture of Raw Film 1]

[0228] The granular molded body obtained in Production Example 1 was obtained using a hot-melt extrusion film forming machine (product name "Measuring Extruder TypeMe-20 / 2800V3", manufactured by Optical Control Systems Co., Ltd.) with a T-die head, according to a thickness of 200 μm. , A method of winding a film with a width of 120 mm around a roll at a speed of 1.5 m / min to obtain a film molded body (hereinafter, may be referred to as raw material film 1).

[0229] The operating conditions of the film forming machine are as follows.

[0230] · Cylinder temperature setting = 280°C ~ 290°C

[0231] · Die head temperature = 270°C

[0232] ·Screw speed=30rpm

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com