Na3V2(PO4)3 cathode material for sodium-ion battery as well as preparation and application of cathode material

A technology of sodium ion battery and sodium vanadium phosphate, which is applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of increasing production costs, and achieve the effects of increasing effective reaction sites, simple and easy preparation process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

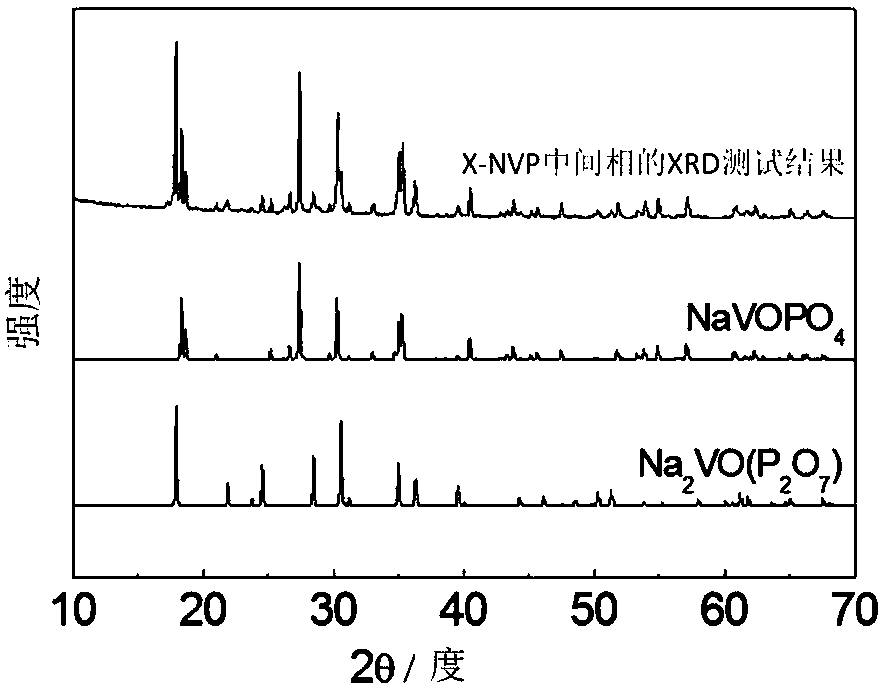

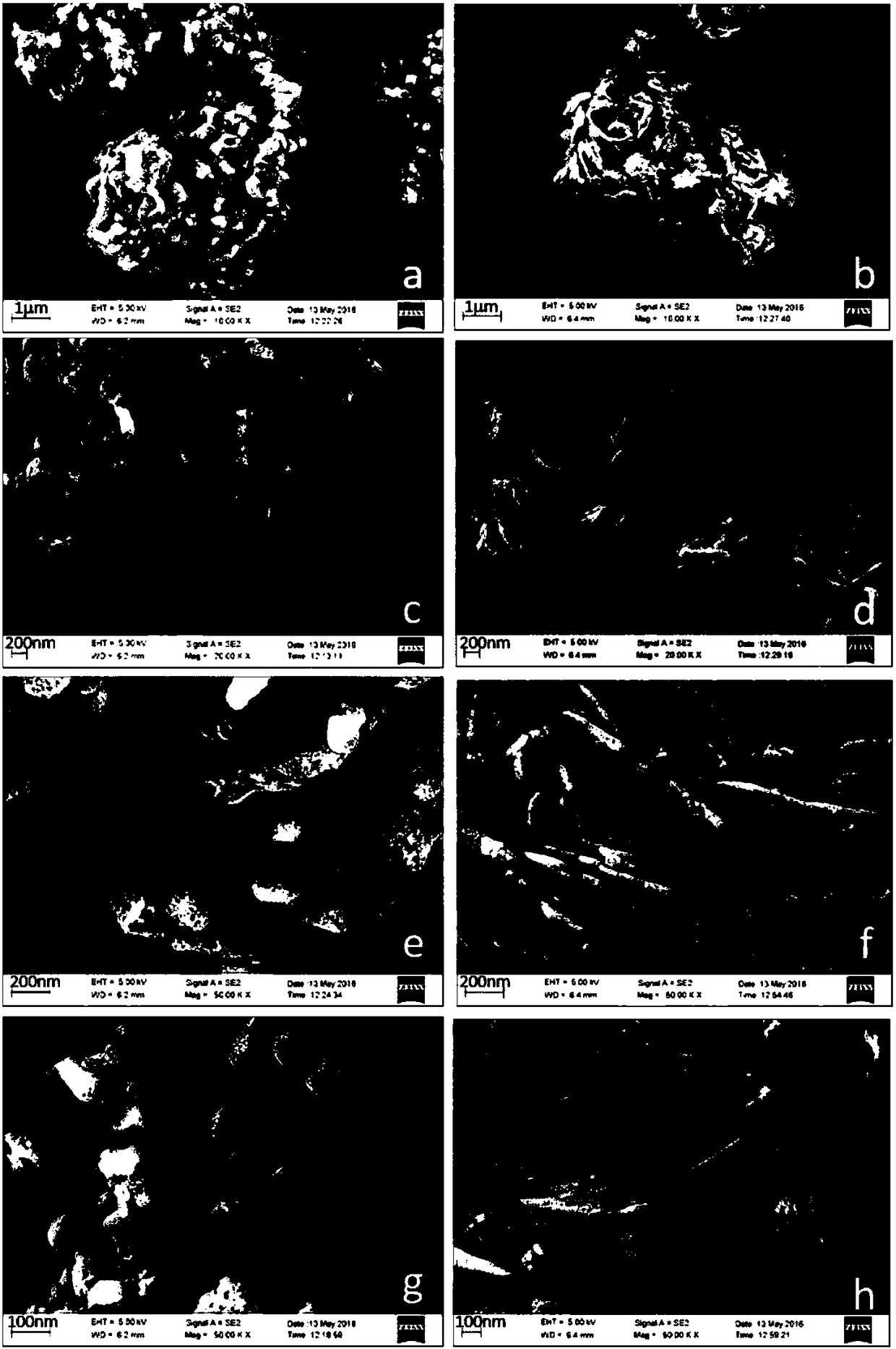

Embodiment 1

[0027] Mix sodium hydroxide, ammonium dihydrogen phosphate, and ammonium metavanadate at a stoichiometric ratio of 3:2:3, place in an 800-degree muffle furnace, and keep the temperature for 1 hour; after cooling, take the mixture out of the muffle furnace , Grind into solid powder intermediate phase A, mix intermediate phase A and sucrose at a mass ratio of 7:3, and add 30ml of deionized water to configure suspension B; place suspension B in a ball mill jar Ball milling, the ball milling speed is 480rpm, and the ball milling time is 10h; after the ball milling, put the suspension B in an oven at 100°C for 12 hours and dry it at a constant temperature; after returning to room temperature, grind the dried suspension B into In the form of solid powder, place it in a tube furnace containing an argon atmosphere at a constant temperature of 350 degrees for 5 hours to remove excess water and gas to form a precursor C of sodium vanadium phosphate; take the precursor C out of the tube f...

Embodiment 2

[0029] Mix sodium hydroxide, ammonium dihydrogen phosphate, and ammonium metavanadate at a stoichiometric ratio of 3:2:3, place in an 800-degree muffle furnace, and keep the temperature for 1 hour; after cooling, take the mixture out of the muffle furnace , Grind into solid powder interphase A, mix interphase A and sucrose at a mass ratio of 3:1, and add 30ml of deionized water to configure suspension B; place suspension B in a ball mill jar Ball milling, the ball milling speed is 480rpm, and the ball milling time is 10h; after the ball milling, put the suspension B in an oven at 100°C for 12 hours and dry it at a constant temperature; after returning to room temperature, grind the dried suspension B into In the form of solid powder, place it in a tube furnace containing an argon atmosphere at a constant temperature of 350 degrees for 5 hours to remove excess water and gas to form a precursor C of sodium vanadium phosphate; take the precursor C out of the tube furnace, and Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com