Solid electrolyte interface membrane-coated negative electrode material composite material, preparation method and use thereof

A solid electrolyte and negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor thermal stability and poor safety performance, achieve suppression of expansion, high structural stability and thermal stability, and solve thermal problems. The effect of runaway problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

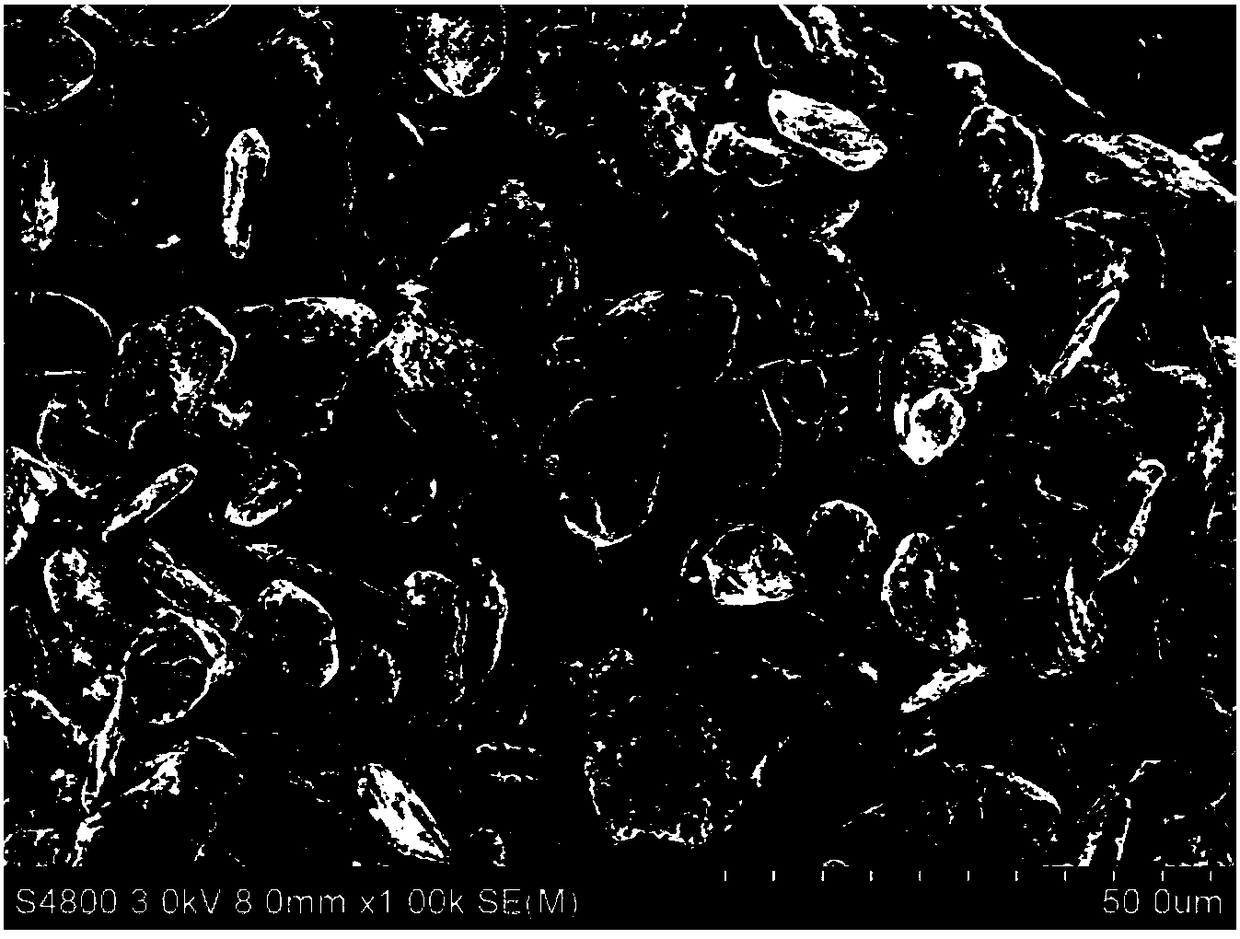

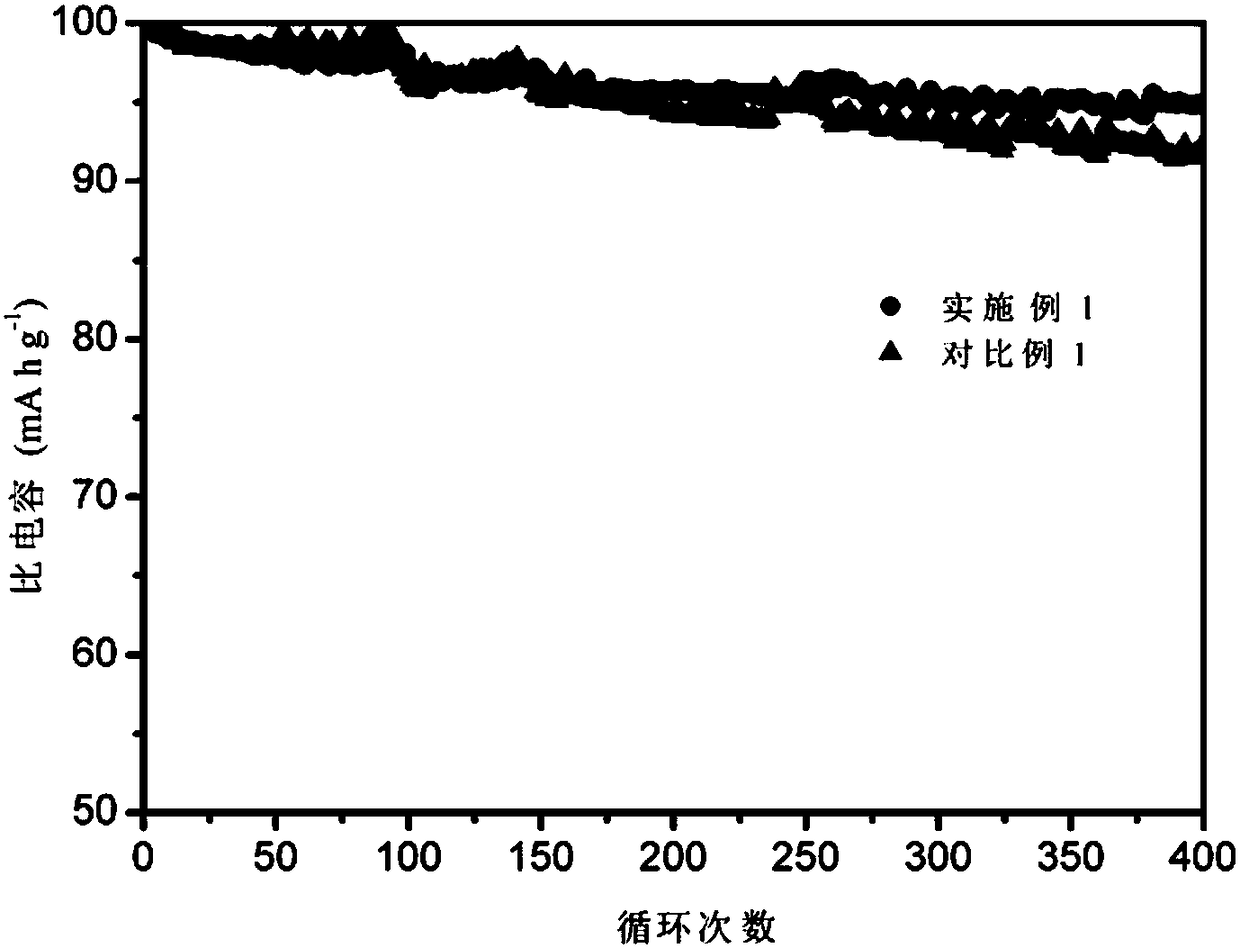

Embodiment 1

[0073] (1) Add a certain quality of aluminum nitrate nonahydrate and stabilizer TX-100 into an appropriate amount of deionized water, and continue to stir mechanically at 600rpm until the aluminum nitrate is dissolved. 2 / g~15m 2 / g flake artificial graphite powder to make it completely dispersed, the mass ratio of aluminum nitrate nonahydrate: TX-100: deionized water: flake artificial graphite is 1.9:2:7:5. The above mixed solution was heated in a water bath until the temperature of the internal reaction system was 75°C. Take a certain amount of urea, dissolve it in an appropriate amount of deionized water, and stir it with a glass rod to dissolve. During this process, the mass ratio of urea: deionized water is 6.1:10. Add the aqueous solution of urea into the above-mentioned mechanically stirred mixed solution by means of a peristaltic pump feeding, and then mechanically stir for 0.5h to mix evenly after the feeding is completed;

[0074] The temperature of the whole proce...

Embodiment 2

[0082] (1) Add a certain amount of aluminum chloride hexahydrate and sodium carboxymethyl cellulose into an appropriate amount of deionized water, stir and dissolve with a glass rod, and then add a median particle size of 10 μm to 20 μm under continuous mechanical stirring at a speed of 500 rpm. Surface area 1m 2 / g~15m 2 The quasi-spherical natural graphite powder of / g makes it completely dispersed, and the aluminum chloride hexahydrate added in this process: sodium carboxymethyl cellulose: deionized water: the mass ratio of natural graphite is: 0.5:5:7: 5. The above mixed solution was heated in a water bath until the temperature of the internal reaction system was 50°C. A certain amount of ammonia water (25wt.%) was dispersed in an appropriate amount of deionized water, stirred with a glass rod, and the mass ratio of ammonia water: deionized water in the process was 1.1:1. Use a peristaltic pump to add the above-mentioned ammonia solution to the above-mentioned mechanica...

Embodiment 3

[0087] (1) Add a certain amount of aluminum sulfate and TX-100 into an appropriate amount of deionized water, stir and dissolve, then add a medium particle size of 10 μm to 20 μm and a specific surface area of 1m under continuous mechanical stirring. 2 / g~15m 2 / g of spherical natural graphite powder to make it completely dispersed, the mass ratio of aluminum sulfate: TX-100: deionized water: graphite powder is 1:4:7:5. The above mixed solution was heated in a water bath until the temperature of the internal reaction system was 65°C. Take a certain amount of sodium hydroxide, dissolve it in an appropriate amount of deionized water, and stir to dissolve. During this process, the mass ratio of sodium hydroxide: deionized water is 0.24:1. Add the sodium hydroxide aqueous solution to the above-mentioned mechanically stirred mixed solution with a peristaltic pump, and then mechanically stir for 0.5h to mix evenly after the feeding is complete;

[0088] The temperature of the wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com