Short tail rivet pulling fastening suite, disassembly and assembly tool and using method of disassembly and assembly tool

A short tail and kit technology, applied in the direction of threaded fasteners, rivets, connecting components, etc., can solve the problems of positioning accuracy, high positioning method requirements, difficult processing of grooves and buckles, and low life of buckles, etc., to achieve Reduce difficulty, disperse stress concentration effect, easy to process and manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

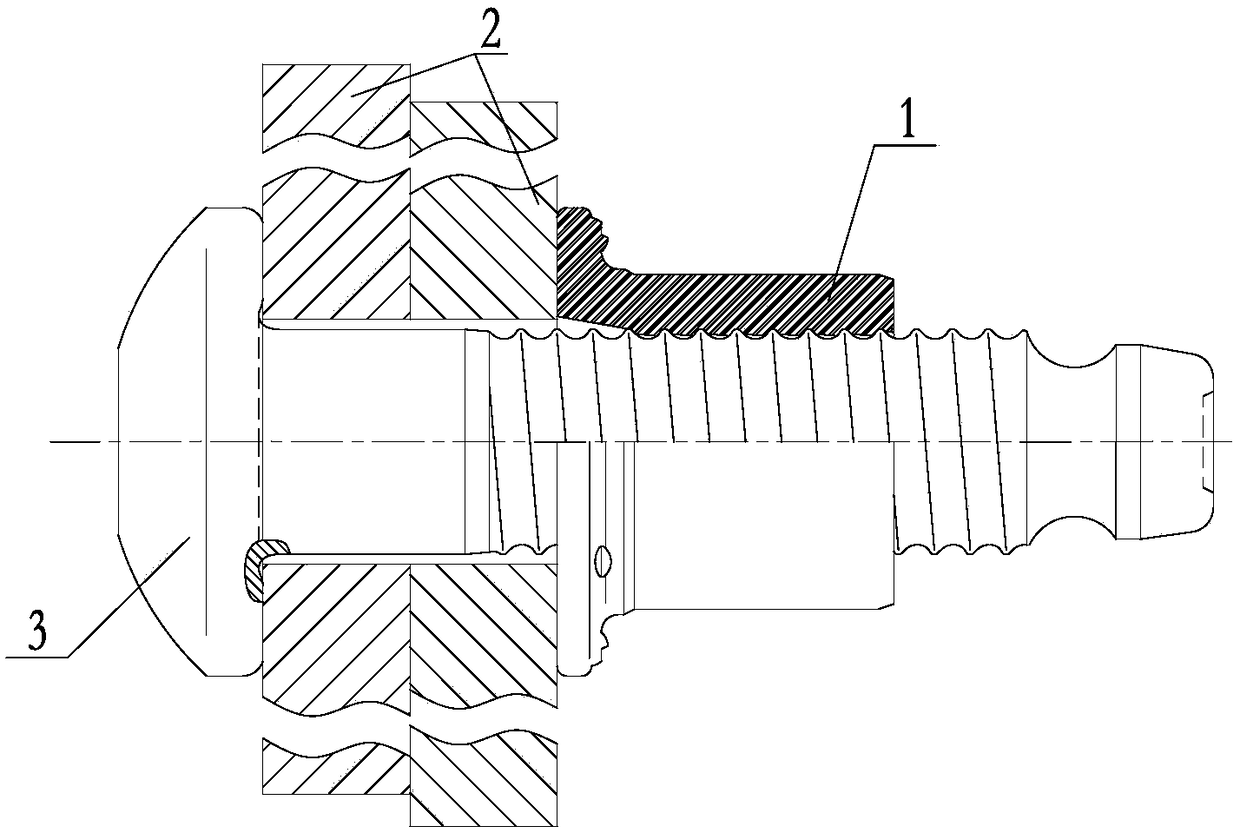

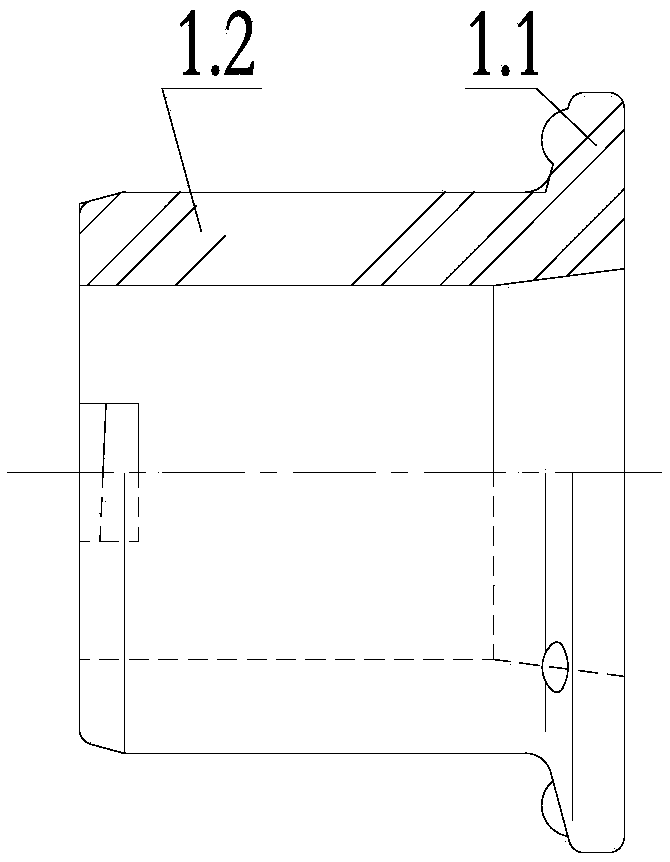

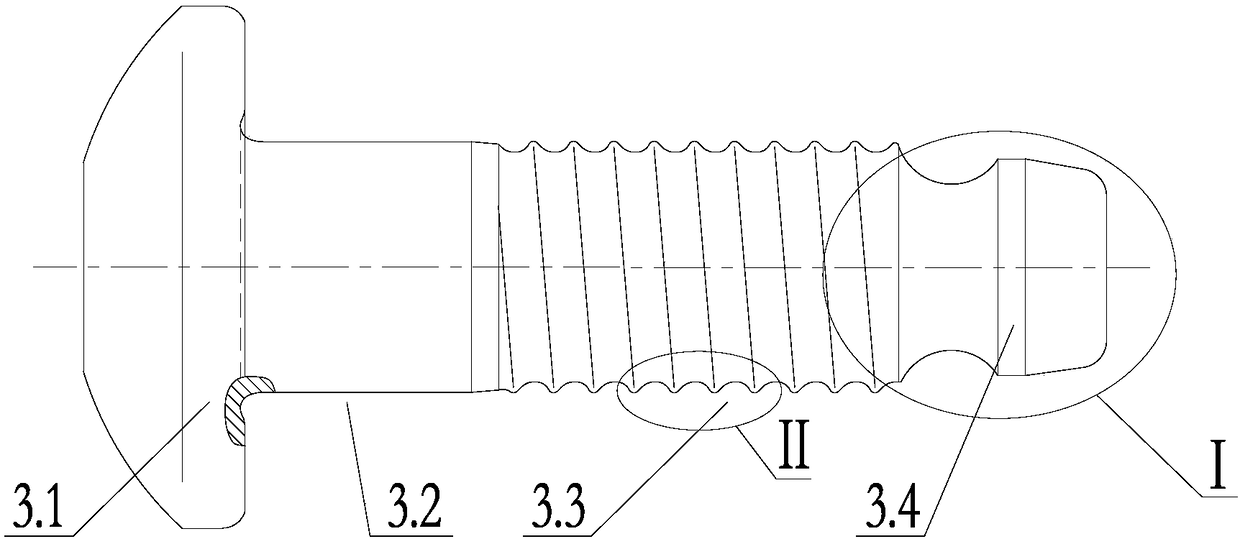

[0071] Such as Figure 1-Figure 5 As shown, this embodiment discloses a short-tail 3.4 blind rivet fastening kit, which includes a blind rivet bolt and a collar 1 matched with the blind rivet bolt; the blind rivet bolt includes a nail head 3.1 and a screw rod, and the screw rod includes The smooth section, the threaded section and the short tail 3.4 connected in sequence; the collar 1 includes a flange base 1.2 and a sleeve 1.1; the collar 1 is installed on the threaded section.

[0072] Specifically, the short tail 3.4 blind rivet fastening kit has the following characteristics:

[0073] 1) The short tail 3.4 includes a smooth spherical groove 3.4.1 and an axial locking step 3.4.2, and the part of the spherical groove 3.4.1 is treated by high-frequency induction quenching.

[0074] 2) The ratio of the spherical surface diameter to the width of the spherical groove 3.4.1 is 1-1.3.

[0075] 3) The cross section of the short tail 3.4 is circular, and the ratio of the maximum d...

Embodiment 2

[0086] This embodiment discloses a disassembly tool for installing and disassembling a short tail 3.4 blind rivet fastening kit disclosed in Embodiment 1, including a hydraulic station, oil pipe, driving device, installation kit and disassembly kit, hydraulic station Connect the driving device through the oil pipe, and the driving device is connected to the installation kit or the removal kit.

[0087] In this embodiment, the driving device is a hydraulic rod or a hydraulic cylinder.

[0088] Both the installation kit and the disassembly kit include an anvil 4.1 and an elastic buckle 4.2, and the anvil 4.1 is made of high-strength, high-hardness alloy steel material.

[0089] The anvil 4.1 is in the shape of a circular tube and the anvil 4.1 is relatively fixed to the driving device. The elastic buckle 4.2 is located in the lumen of the anvil 4.1. The elastic buckle 4.2 includes a plurality of circumferentially arranged clips, and the outer end of the clip is provided with a ...

Embodiment 3

[0094] Such as Figure 6-Figure 14 As shown, this embodiment discloses a specific method of using the disassembly tool in Embodiment 2, specifically including an installation method and a disassembly method.

[0095] The installation method includes the following steps:

[0096] S101: passing the blind rivet bolt through the through hole on the member 2, and putting the collar 1 on the threaded section;

[0097] S102: Insert the short tail 3.4 into the front end of the elastic buckle 4.2, so that the chuck head of the elastic buckle 4.2 contacts the spherical groove 3.4.1;

[0098] S103: Connect the installation kit with the driving device and start the hydraulic station. Under the action of the driving rod, the elastic buckle 4.2 moves into the anvil 4.1 tube cavity, and under the action of the anvil 4.1 tube wall, the clamp head of the elastic buckle 4.2 Buckle into the spherical pull groove 3.4.1 and engage;

[0099] S104: The elastic buckle 4.2 continues to move toward ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com