Modification method for polypropylene fibers

A polypropylene fiber and modification technology, applied in the direction of fiber type, fiber treatment, textile and paper making, etc., can solve the problems of low surface energy of polypropylene, poor physical and chemical adhesion, lack of active functional groups in molecular chain, etc. The effect of increasing the degree and enhancing the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A modification method of polypropylene fiber, comprising the following steps:

[0072] (1) After the polypropylene fiber is degreased, it is dried to constant weight and set aside;

[0073] (2) Preparation of chromic acid solution:

[0074] Proportion by mass, K 2 Cr 2 o 7 :H 2 O: Concentrated H 2 SO 4 =5:8:75, mix the three and react for 5 minutes to obtain chromic acid;

[0075] (3) Weigh the polypropylene fiber with constant weight, put it into the chromic acid solution, soak it at room temperature for 0.5h, and then react, the reaction temperature is 65-70°C, and the reaction time is 4min;

[0076] (4) The reacted polypropylene fibers are washed with distilled water, filtered, and dried in an oven at 80° C. for 8 hours, and then dried in a desiccator to constant weight to obtain modified polypropylene fibers;

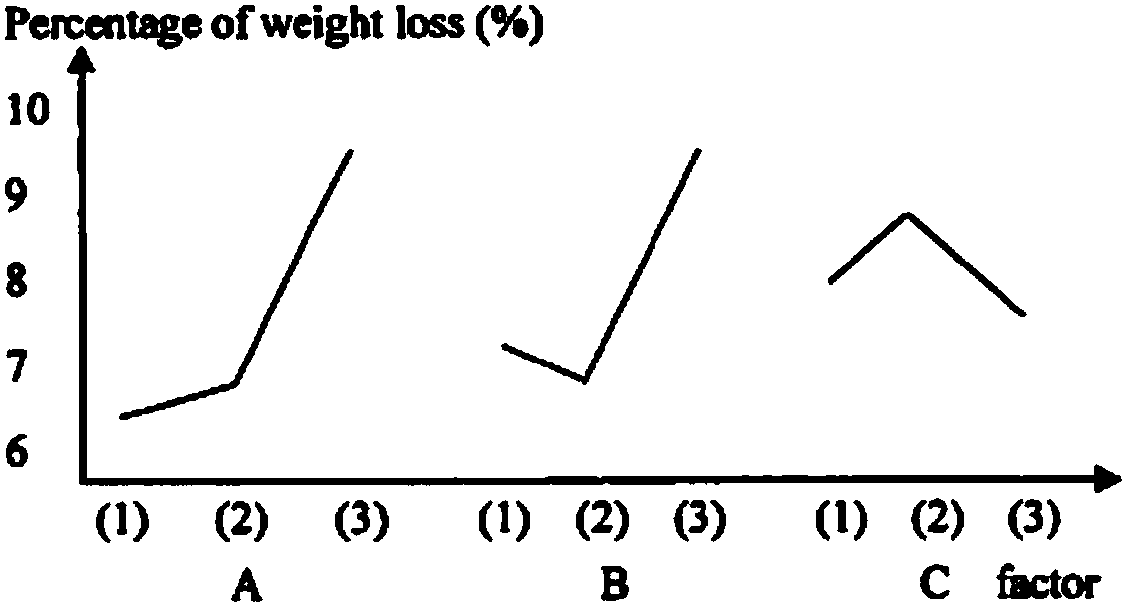

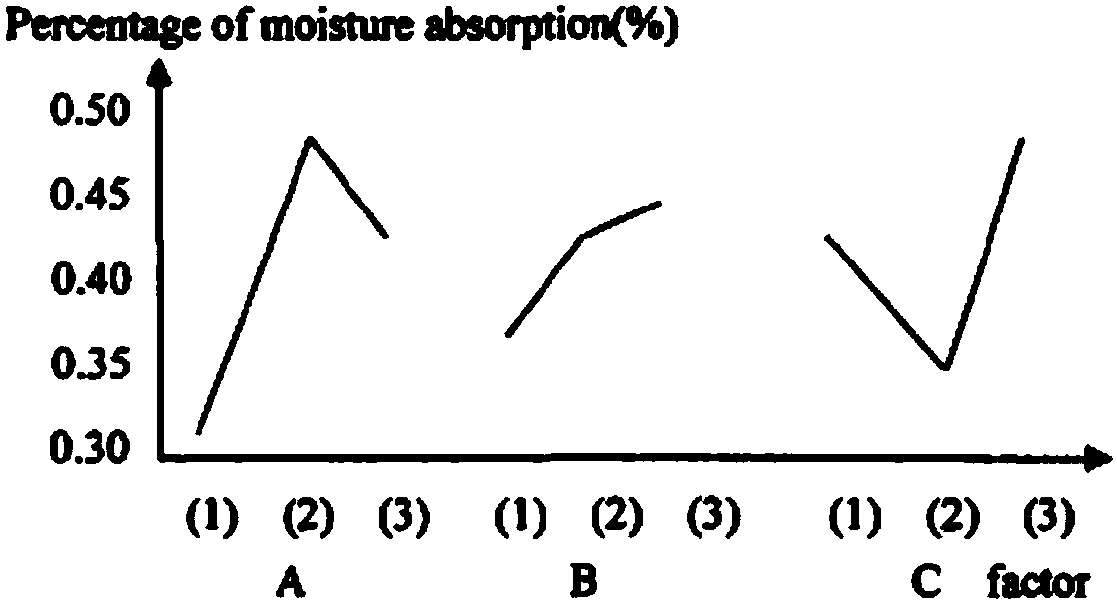

[0077] (5) Calculate the weight loss rate and moisture absorption rate of the modified polypropylene fiber, the weight loss rate is 6.34%, and the mo...

Embodiment 2

[0079] A modification method of polypropylene fiber, comprising the following steps:

[0080] (1) After the polypropylene fiber is degreased, it is dried to constant weight and set aside;

[0081] (2) Preparation of chromic acid solution:

[0082] Proportion by mass, K 2 Cr 2 o 7 :H 2 O: Concentrated H 2 SO 4 =5:8:100, mix the three and react for 8 minutes to obtain chromic acid;

[0083] (3) Weigh the constant-weight polypropylene fiber, put it into the chromic acid solution, soak it at room temperature for 2.5 hours, and then react, the reaction temperature is 65-70°C, and the reaction time is 4 minutes;

[0084] (4) The reacted polypropylene fibers are washed with distilled water, filtered, and dried in an oven at 80° C. for 8 hours, and then dried in a desiccator to constant weight to obtain modified polypropylene fibers;

[0085] (5) Calculate the weight loss rate and moisture absorption rate of the modified polypropylene fiber, the weight loss rate is 6.82%, and ...

Embodiment 3

[0087] A modification method of polypropylene fiber, comprising the following steps:

[0088] (1) After the polypropylene fiber is degreased, it is dried to constant weight and set aside;

[0089] (2) Preparation of chromic acid solution:

[0090] Proportion by mass, K 2 Cr 2 o 7 :H 2 O: Concentrated H 2 SO 4 =5:8:125, mix the three and react for 10 minutes to obtain chromic acid;

[0091] (3) Weigh the polypropylene fiber with constant weight, put it into the chromic acid solution, soak it at room temperature for 2.5h, and then react, the reaction temperature is 65-70°C, and the reaction time is 8min;

[0092] (4) The reacted polypropylene fibers are washed with distilled water, filtered, and dried in an oven at 80° C. for 8 hours, and then dried in a desiccator to constant weight to obtain modified polypropylene fibers;

[0093] (5) Calculate the weight loss rate and moisture absorption rate of the modified polypropylene fiber, the weight loss rate is 13.90%, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com