Automated replacing device of copper pipe horizontal continuous casting filter

A horizontal continuous casting and filter technology, which is applied in the field of copper tube horizontal continuous casting equipment, can solve the problems of equipment damage, liquid splashing, time-consuming and labor-intensive problems, and achieve stability and uniformity, prevent turbulent splashing, and smooth replacement process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

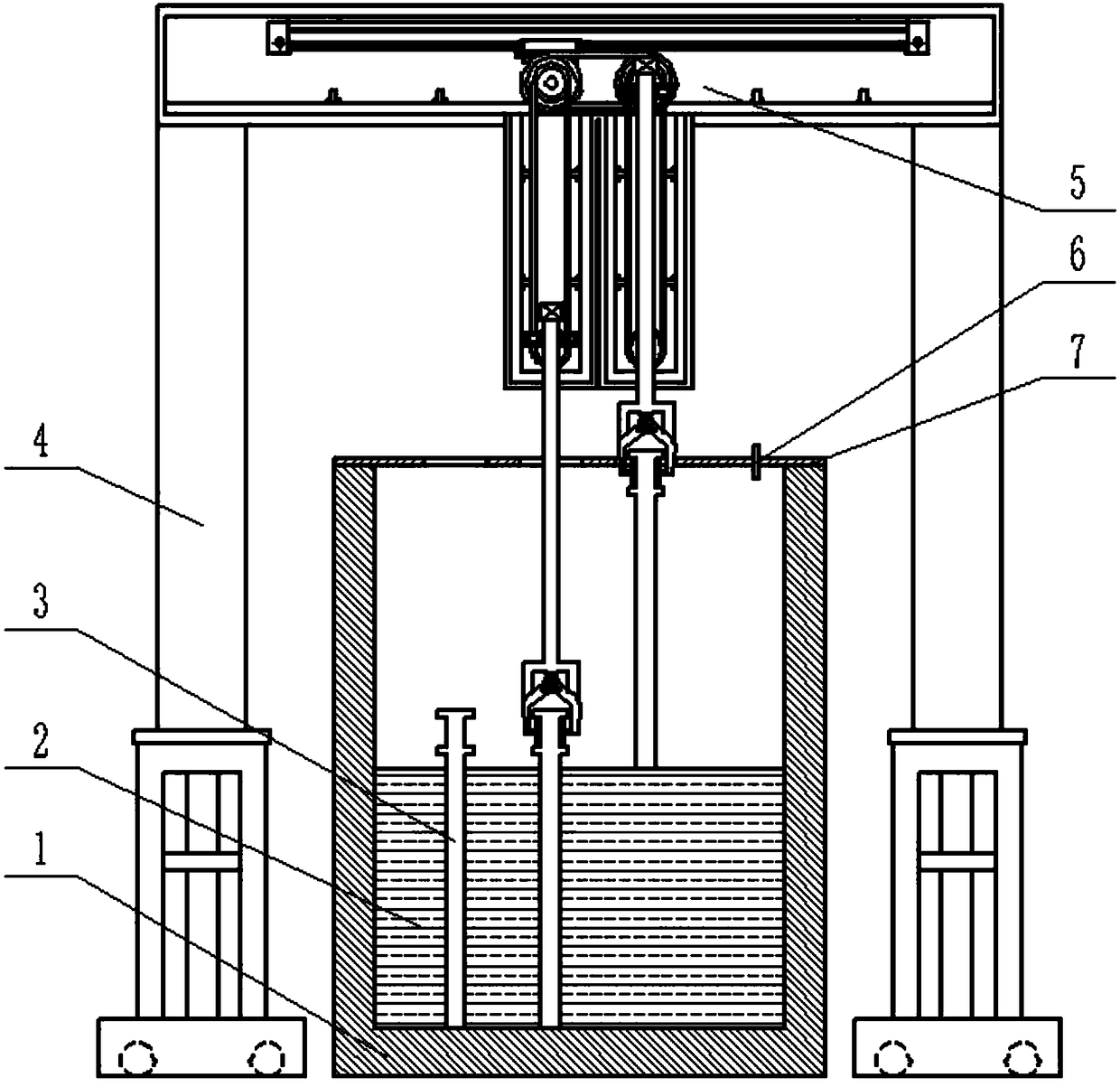

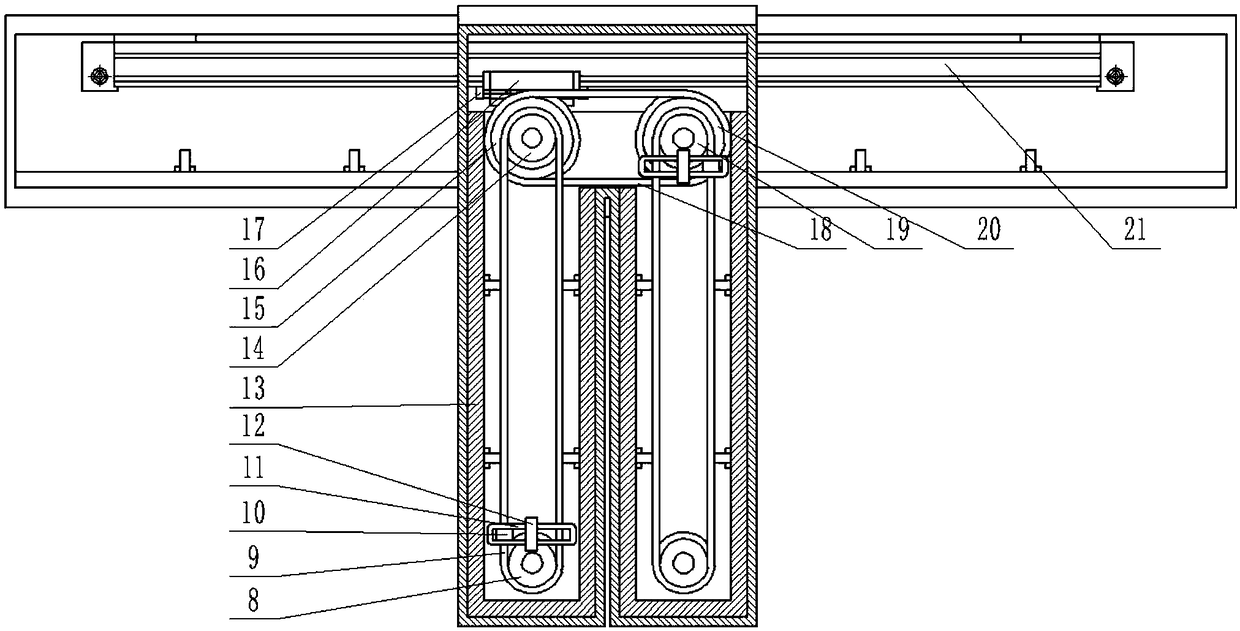

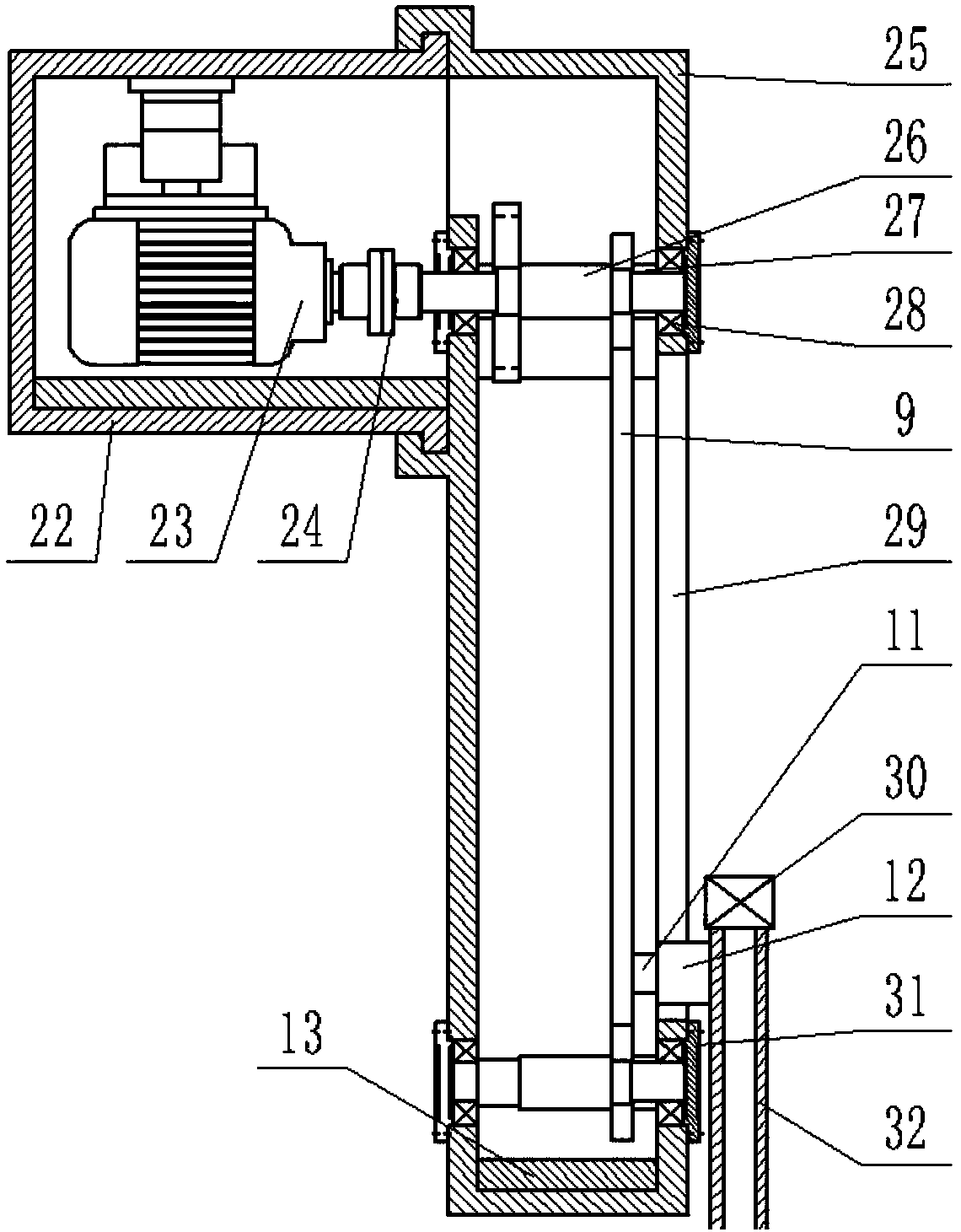

[0019] exist figure 1 , figure 2 with image 3 In the schematic diagram of the automatic replacement device for the copper tube horizontal continuous casting filter shown, the hydraulic lifting device 4 is two hydraulic cylinders with a movable mechanism at the bottom, and their upper ends are connected with the frame of the replacement device 5 respectively. The shells are connected at both ends. Described frame shell is made up of two parts of side opening channel steel type fixed shell 22 and two box type mobile shells 25 that are located on its side opening, as Figure 4 As shown, the two horizontal ends of the fixed housing are respectively provided with vertical eversion edges, and the mobile housing is provided with two corresponding horizontal bar-shaped grooves, and the eversion edges and the bar-shaped grooves form a sliding pair. , there is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com